Silicon or silicon alloy composite lithium ion battery negative electrode material containing lithium bis(oxalate)borate as well as preparation method and application of negative electrode material

A technology of lithium bisoxalatoborate and lithium oxalateborate, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low solubility, low conductivity, poor low temperature performance and hygroscopicity, etc. Long cycle life, excellent film-forming ability, improved electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Commercial silicon powder and high-purity iron powder were loaded into a high-energy ball mill filled with argon at a mass ratio of 9:1 for mechanical alloying, and ferrosilicon alloy powder was obtained after high-energy ball milling for 10 hours. Then ball mill the powder with citric acid and acetylene black at a mass ratio of 5:5:1, ball mill for 1 hour under an argon protective atmosphere, and then carbonize at 600°C for 30 minutes under a nitrogen-hydrogen mixed protective gas. The mass percentage of the carbon material was measured to be 19.5% by means of elemental testing and analysis. Then add 5% lithium bisoxalate borate, stir and mix to obtain a ferrosilicon alloy-18.6% carbon-4.7% lithium bisoxalate borate composite lithium ion battery negative electrode material.

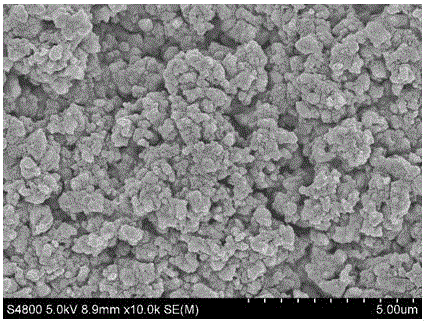

[0054] figure 1 Scanning electron micrograph of the ferrosilicon alloy-18.6% carbon-4.7% bisoxalate lithium borate composite lithium ion battery negative electrode material prepared in Example 1 ...

Embodiment 2

[0060] Commercial silicon powder, sucrose, and acetylene black were mixed by high-energy ball milling at a mass ratio of 6:3.5:0.5, ball milled for 30 minutes under an argon protective atmosphere, and then carbonized at 700°C for 1 hour under a nitrogen-hydrogen mixed protective gas. The mass percentage of the carbon material was measured to be 10.9% by means of an elemental test and analysis method. Then add 1% lithium bisoxalate borate, stir and mix to obtain a silicon-10.9% carbon-1% lithium bisoxalate borate composite lithium ion battery negative electrode material. Figure 5 The cycle curve of the silicon-10.9% carbon-1% bisoxalate lithium borate composite lithium ion battery negative electrode material prepared in Example 2 of the present invention under the charge and discharge condition of 300 mA / g. Its first reversible (charging) capacity reaches 1858 mAh / g, and after 100 cycles, the capacity is 1411 mAh / g, and the capacity retention rate is 75.9%, showing excellent c...

Embodiment 3

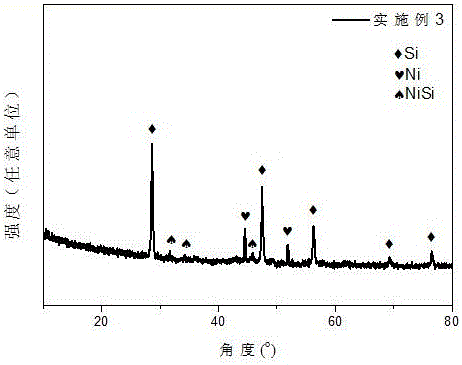

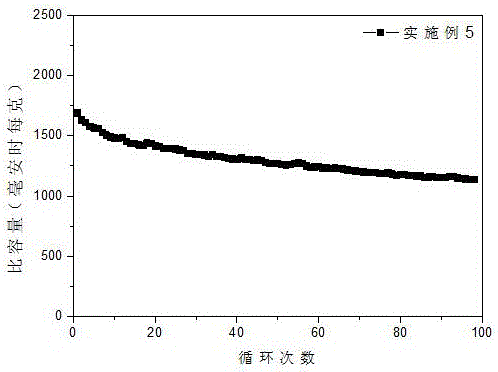

[0063] Commercial silicon powder and nickel powder are smelted at high temperature under argon protective gas at a mass ratio of 3:2, followed by high-temperature atomization to obtain silicon-nickel alloy powder. Then the powder and vapor-phase-grown carbon fiber were mixed by high-energy ball milling at a mass ratio of 7:3, ball milled for 16 hours under an argon protective atmosphere, and then 10% by mass percentage of lithium dioxalate borate was added for stirring and mixing to obtain A silicon-nickel alloy-27.3% carbon-9.1% lithium bisoxalate borate composite lithium-ion battery negative electrode material. Figure 6 For the XRD test results of the silicon-nickel alloy-27.3% carbon-9.1% lithium dioxalate borate composite lithium ion battery negative electrode material prepared in Example 3 of the present invention, obvious silicon and nickel elements can be seen from the figure, and there are Nickel-silicon alloy formation. Figure 7 The cycle curve of the silicon-nicke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com