Method for improving rate capability of ternary cathode material of lithium ion battery

A lithium-ion battery and positive electrode material technology, applied in the field of new energy materials and energy storage devices, can solve the problems of material rate performance deterioration, cycle performance deterioration, specific capacity reduction, etc., achieve fast drying speed, improve rate performance, and cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

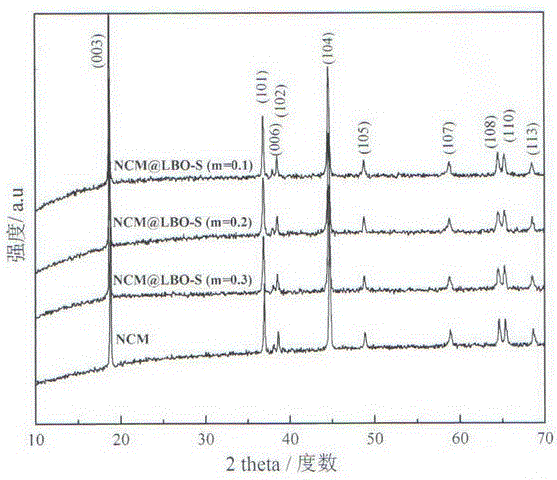

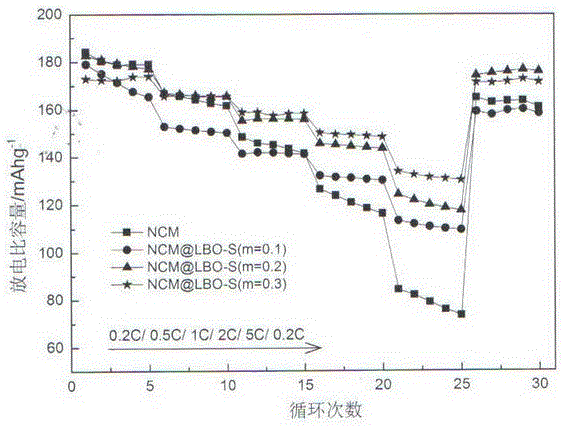

[0022] a. Mix lithium carbonate, boron trioxide and lithium sulfate in a molar ratio of Li:B:S=1:2:0.1, add to deionized water, stir at a constant speed for 0.5h, and wait until the mixture is completely dissolved to obtain a coating solution;

[0023] b. LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The ternary cathode material is LiNi according to the mass ratio 1 / 3 co 1 / 3 mn 1 / 3 o 2 : Li 2 O-2B 2 o 3 -mLi 2 SO 4 =100:5 mixing, slowly adding to the coating solution obtained in step a, maintaining a stirring speed of 100r / min, and stirring into a uniform slurry;

[0024] c. Spray-dry the slurry obtained in step b, control the inlet temperature to 220°C, and the outlet temperature to 110°C, and collect the dried powder;

[0025] d. Put the dried powder in step c into a muffle furnace for heat treatment at a temperature of 500° C., a heating rate of 5° C. / min, and a time of 10 hours to obtain a mixture;

[0026] e, the mixture obtained in step d is ground evenly, and 200 mesh sieves ...

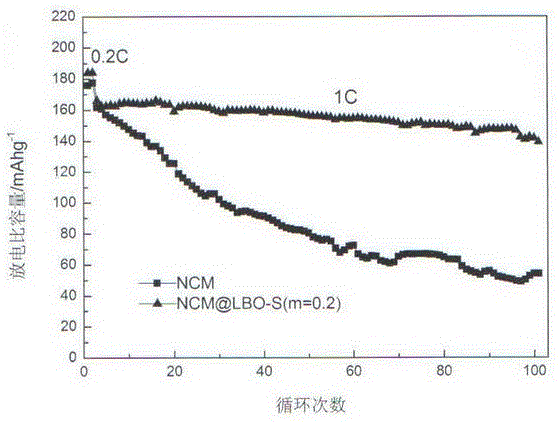

Embodiment 2

[0028] a. Mix lithium carbonate, boric acid, and lithium sulfate in a molar ratio of Li:B:S=1:2:0.2, add to deionized water, stir at a constant speed for 0.5h, and wait until the mixture is completely dissolved to obtain a coating solution;

[0029] b. LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The ternary cathode material is LiNi according to the mass ratio 1 / 3 co 1 / 3 mn 1 / 3 o 2 : Li 2 O-2B 2 o 3 -mLi 2 SO 4 = 100:3 mixing, slowly adding to the coating solution obtained in step a, maintaining a stirring speed of 150r / min, and stirring into a uniform slurry;

[0030] c. Spray-dry the slurry obtained in step b, control the inlet temperature to 220°C, and the outlet temperature to 110°C, and collect the dried powder;

[0031] d. Put the dried powder in step c into a muffle furnace for heat treatment at a temperature of 500° C., a heating rate of 5° C. / min, and a time of 10 hours to obtain a mixture;

[0032] e, the mixture obtained in step d is ground evenly, and 200 mesh sieves ar...

Embodiment 3

[0034] a. Mix lithium hydroxide, boric acid, and lithium sulfate in a molar ratio of Li:B:S=1:2:0.3, add to deionized water, stir at a constant speed for 1 hour, and wait until the mixture is completely dissolved to obtain a coating solution;

[0035] b. LiNi 0.5 co 0.2 mn 0.3 o 2 The ternary cathode material is LiNi according to the mass ratio 0.5 co 0.2 mn 0.3 o 2 : Li 2 O-2B 2 o 3 -mLi 2 SO 4 =100:1 mixing, slowly adding to the coating solution obtained in step a, maintaining a stirring speed of 200r / min, and stirring into a uniform slurry;

[0036] c. Spray-dry the slurry obtained in step b, control the inlet temperature to 220°C, and the outlet temperature to 110°C, and collect the dried powder;

[0037] d. Put the dried powder in step c into a muffle furnace for heat treatment at a temperature of 550° C., a heating rate of 5° C. / min, and a time of 10 hours to obtain a mixture;

[0038] e, the mixture obtained in step d is ground evenly, and 200 mesh sieves a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com