Gas sensor based on selective wave bands and detection method thereof

A gas sensor and sensor technology, applied in the direction of color/spectral characteristic measurement, instruments, measuring devices, etc., can solve the problems of poor selectivity and low sensitivity, and achieve the effects of improving stability, improving selectivity and reducing aging problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

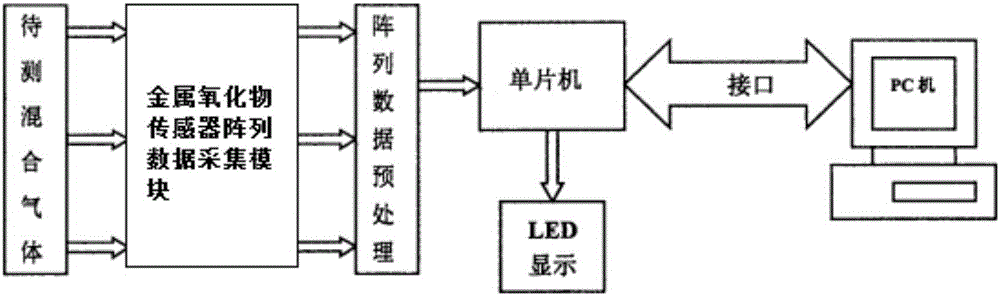

Image

Examples

Embodiment 1

[0029] see figure 1 and figure 2As shown, a gas sensor based on a selective wavelength band provided in this embodiment includes a packaging assembly 4, a metal oxide sensor array 1 and a light source 2, and the packaging assembly 4 combines the oxide sensitive material 3 of the metal oxide sensor array 1 and the The light source 2 is enclosed in a sealed space, and the packaging assembly 4 includes an air inlet 5 and an air outlet 6. The light source 2 is a light source with variable wavelength. In this embodiment, only one light source with variable wavelength is used, which can reduce the volume of the sensor. The wavelength band of the light source (range of wavelength) includes 180-254nm, 300-320nm, 340-360nm, 365-400nm and 500-600nm, and the metal oxide sensor array is provided with different oxide sensitive materials , under the irradiation of light of a certain wavelength band mentioned above, at least one metal oxide sensor has a higher sensitivity to a certain gas ...

Embodiment 2

[0048] The difference between the technical solution of this embodiment and that of Embodiment 1 is only the difference in the setting of the light source. In this embodiment, only the different parts are described, and the same parts will not be repeated. The light source in this embodiment is a plurality of light sources with fixed wavelength ranges. The variable light sources are separated and no longer continuously changed. Instead, they are made into fixed light sources with different wavelength ranges, and the gas sensor array unit is repeated, and then combined. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com