UV glue and preparation method thereof

A methyl and monomer technology, applied in the field of UV-curable coatings, can solve problems such as insufficient bonding strength and limited use of UV-curable adhesives, and achieve good thixotropy, easy processing and use, and good aging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

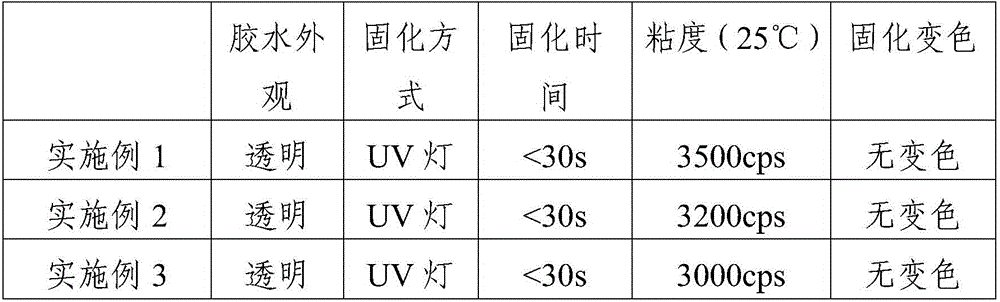

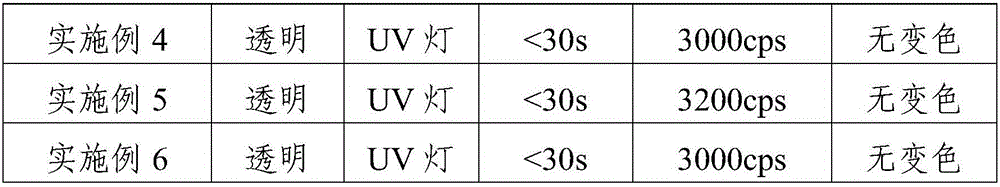

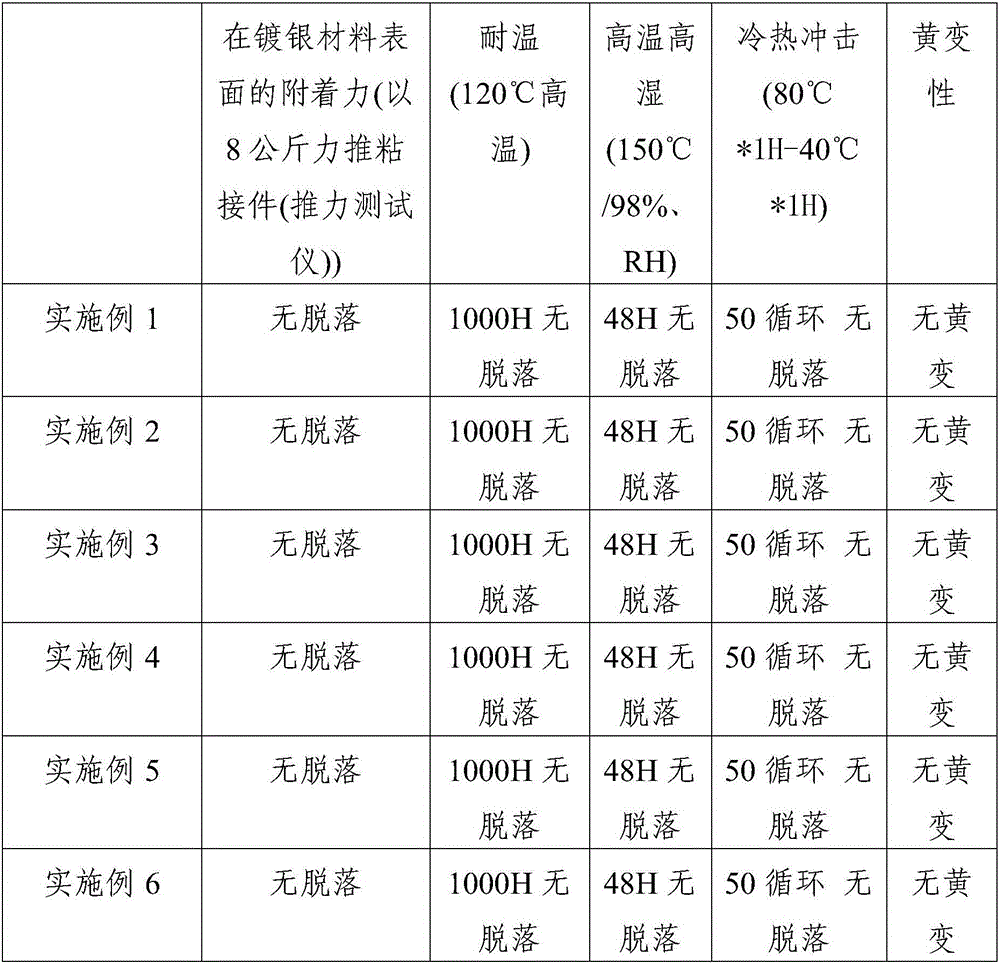

Examples

Embodiment 1

[0033]Accurately weigh each raw material by the following weight percentages, the 624-100 epoxy acrylate of Changxing Chemical: 20%, the 6141H-80 aliphatic polyurethane acrylate of Changxing Chemical: 35%, IBOA isobornyl acrylate: 25%, EM214 ( Tetrahydrofuran acrylate): 15%, photoinitiator 184 (1-hydroxycyclohexyl benzophenone): 2%, photoinitiator TPO (2,4,6-trimethylbenzoyl diphenylphosphine oxide): 2%, KH560 (γ-glycidyl etheroxypropyl trimethoxysilane): 0.5%, antioxidant 1010 (tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] Pentaerythritol ester): 0.5%; Add the above-mentioned components in the double planetary power mixing mixer in turn, vacuumize until the vacuum degree is -0.08MPa, stir at 700 rpm for 1-2 hours, stir evenly, and let it air to room temperature , to obtain a UV-curable adhesive with good adhesion to the silver-plated layer, and seal the package.

Embodiment 2

[0035] Accurately weigh each raw material by the following weight percentages, 624-100 epoxy acrylate of Changxing Chemical: 20%, 6141H-80 aliphatic polyurethane acrylate of Changxing Chemical: 35%, IBOMA isobornyl methacrylate: 25%, EM214 (tetrahydrofuran acrylate): 15%, photoinitiator 184 (1-hydroxycyclohexyl benzophenone): 2%, photoinitiator TPO (2,4,6-trimethylbenzoyl diphenylphosphine oxide ): 2%, KH560 (γ-glycidyl etheroxypropyl trimethoxysilane): 0.5%, antioxidant 1010 (tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propyl Acid] pentaerythritol ester): 0.5%; Add the above-mentioned components in the double planetary power mixing mixer in turn, vacuumize until the vacuum degree is -0.08MPa, stir for 1-2 hours at 700 rpm, stir evenly, and let it air in the air to room temperature to obtain a UV-curable adhesive with good adhesion to the silver-plated layer, which can be sealed and packaged.

Embodiment 3

[0037] Accurately weigh each raw material by the following weight percentages, Changxing Chemical's 624-100 epoxy acrylate: 18%, Changxing Chemical's 6141H-80 aliphatic polyurethane acrylate: 35%, IBOA (isobornyl acrylate): 25%, EM214 (tetrahydrofuran acrylate): 17%, photoinitiator 184 (1-hydroxycyclohexyl benzophenone): 2%, photoinitiator TPO (2,4,6-trimethylbenzoyl diphenylphosphine oxide) : 2%, KH560 (γ-glycidyl etheroxypropyl trimethoxysilane): 0.5%, antioxidant 1010 (tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid ] pentaerythritol ester): 0.5%; the above-mentioned components are added in the double planetary power mixing mixer successively, vacuumized to a vacuum degree of -0.08MPa, stirred for 1-2 hours at 700 rpm, stirred evenly, and left to air until At room temperature, obtain a UV-curable adhesive with good adhesion to the silver-plated layer, and seal the package.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com