Method for preparing polymer blend microspheres

A technology of blends and microspheres, which is applied in the fields of preparing polystyrene-polyester blend microspheres and polymer blending microspheres, can solve the problem that it is difficult to prepare polycondensation polymers and vinyl monomer polymers. problems such as blending microspheres, etc., to achieve the effect of good interphase interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

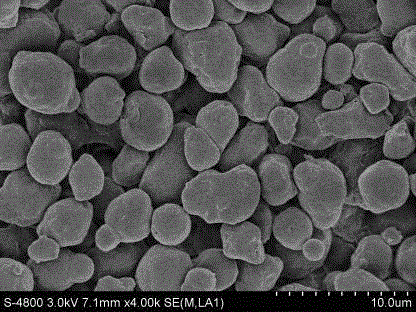

Image

Examples

Embodiment 1

[0017] (1) Dissolve 5 grams of polyester (ES-403, produced by Skybonsk Chemical (Suzhou) Co., Ltd.) in 20 grams of styrene, and place it in a 250-ml three-neck bottle;

[0018] (2) Add 0.35 g of azobisisobutyronitrile, start stirring, and raise the temperature to 55 °C;

[0019] (3) Add a compound emulsifier consisting of 0.4 grams of Span80 and 3.2 grams of Tween 80;

[0020] (4) After stirring for 20 minutes, add 100 ml of deionized water dissolved with 0.3 g of PVA1788, 0.03 g of sodium lauryl sulfate, and 0.2 g of potassium chloride, and increase the stirring speed to 1500 r / min;

[0021] (5) After 30 minutes, reduce the low stirring rate to 600 rpm; raise the temperature to 75 °C for 5 hours, cool down to room temperature, and stop stirring;

[0022] (6) The reaction product is centrifuged, washed and dried to obtain the finished product.

[0023] Example 1 finished product etc. are tested and obtain following result:

[0024] (1) The glass transition temperature Tg wa...

example 2

[0032] (1) Dissolve 9 grams of polyester (ES-403, produced by Skybonsk Chemical (Suzhou) Co., Ltd.) in 40 grams of styrene and place it in a 500 ml three-necked bottle;

[0033] (2) Add 0.7 g of azobisisobutyronitrile, start stirring, and raise the temperature to 55 °C;

[0034] (3) Add a compound emulsifier consisting of 0.6 grams of Span80 and 3.6 grams of Tween 80;

[0035] (4) After stirring for 25 minutes, add 200 ml of deionized water dissolved with 0.6 g of PVA1788, 0.05 g of sodium lauryl sulfate, and 0.4 g of potassium chloride, and increase the stirring speed to 1300 r / min;

[0036] (5) After 35 minutes, reduce the low stirring rate to 550 rpm; raise the temperature to 76 °C for 5 hours, cool down to room temperature, and stop stirring;

[0037] (6) The reaction product is centrifuged, washed and dried to obtain the finished product.

[0038] Example 2 finished product is carried out microsphere particle size and distribution test and obtains following result:

[...

example 3

[0041] (1) Dissolve 6 grams of polyester (ES-403, produced by Skybonsk Chemical (Suzhou) Co., Ltd.) in 30 grams of styrene, and place it in a 500 ml three-neck bottle;

[0042] (2) Add 0.5 g of azobisisobutyronitrile, start stirring, and raise the temperature to 60 °C;

[0043](3) Add a compound emulsifier consisting of 0.5 grams of Span80 and 3.8 grams of Tween 80;

[0044] (4) After stirring for 20 minutes, add 200 ml of deionized water dissolved with 0.5 g of PVA1788, 0.05 g of sodium lauryl sulfate, and 0.4 g of potassium chloride, and increase the stirring speed to 1400 rpm;

[0045] (5) After 30 minutes, reduce the low stirring rate to 500 rpm; raise the temperature to 78 ℃ for 5 hours, cool down to room temperature, and stop stirring;

[0046] (6) The reaction product is centrifuged, washed and dried to obtain the finished product.

[0047] Example 3 finished product is carried out microsphere particle size and distribution test and obtains following result:

[0048]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com