SiO2-containing benzoxazine/bismaleimide resin composite material and preparation method thereof

A technology of maleimide resin and benzoxazine is applied in the field of benzoxazine/bismaleimide resin composite material and preparation thereof, and can solve the problem of poor molding processability, high brittleness of cured product, and high curing temperature. Advanced problems, to achieve the effect of good combination, simple and convenient preparation process, and improved comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A SiO 2 The benzoxazine / bismaleimide resin composite material consists of the following raw materials in parts by weight: 1 part contains SiO 2 benzoxazine monomer, 100 parts of diphenylmethane bismaleimide and 10 parts of allyl ether.

[0035] The above containing SiO 2 The preparation method of benzoxazine / bismaleimide resin composite material, it comprises the steps:

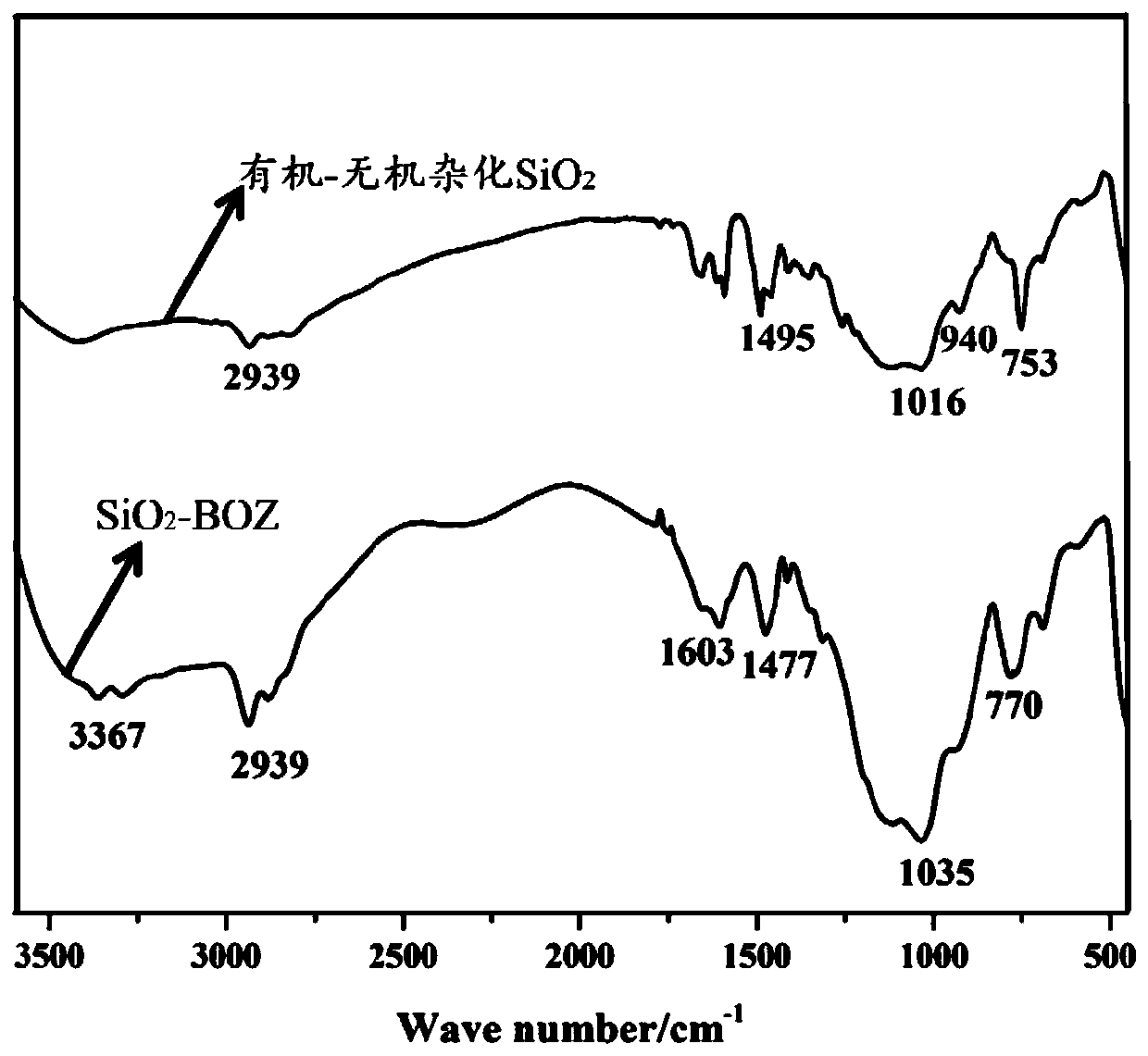

[0036] (1) Contains SiO 2 Preparation of benzoxazine monomers:

[0037] Organic-inorganic hybrid SiO with amino groups at the end 2 Mix it with paraformaldehyde with a degree of polymerization of 8 at a molar ratio of 1:2, pour the mixed solution into a 250mL three-neck flask with a magnet and a condensing reflux tube, set the device on a magnetic stirring electric heating mantle, and install it , start stirring, and raise the temperature to 35°C, stir for 2h; then add phenol, wherein the molar ratio of phenol to paraformaldehyde with a degree of polymerization of 8 is 1:2, then heat up to 120°C, ...

Embodiment 2

[0047] A SiO 2 The benzoxazine / bismaleimide resin composite material consists of the following raw materials in parts by weight: 5 parts containing SiO 2 benzoxazine monomer, 100 parts diphenylmethane bismaleimide and 50 parts allyl ether.

[0048] The above containing SiO 2 The preparation method of benzoxazine / bismaleimide resin composite material, it comprises the steps:

[0049] (1) Contains SiO 2 Preparation of benzoxazine monomers:

[0050] Organic-inorganic hybrid SiO with amino groups at the end 2 Mix it with paraformaldehyde with a degree of polymerization of 20 at a molar ratio of 1:2, pour the mixed solution into a 250mL three-neck flask with a magnet and a condensing reflux tube, set the device on a magnetic stirring electric heating mantle, and install it , start stirring, and raise the temperature to 40°C, stir and react for 1.5h; then add phenol, wherein the molar ratio of phenol to paraformaldehyde with a degree of polymerization of 20 is 1:2, then heat up...

Embodiment 3

[0060] A SiO 2 The benzoxazine / bismaleimide resin composite material consists of the following raw materials in parts by weight: 10 parts containing SiO 2 benzoxazine monomer, 100 parts diphenylmethane bismaleimide and 100 parts allyl ether.

[0061] The above containing SiO 2 The preparation method of benzoxazine / bismaleimide resin composite material, it comprises the steps:

[0062] (1) Contains SiO 2 Preparation of benzoxazine monomers:

[0063] Organic-inorganic hybrid SiO with amino groups at the end 2 Mix with paraformaldehyde with a degree of polymerization of 50 at a molar ratio of 1:2, pour the mixture into a 250mL three-neck flask with a magnet and a condensing reflux tube, and set the device on a magnetic stirring electric heating mantle. After installation , start stirring, and raise the temperature to 45°C, stir and react for 1h; then add phenol, wherein the molar ratio of phenol to paraformaldehyde with a degree of polymerization of 50 is 1:2, then heat up t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com