Production method for medical pressure-sensitive adhesive tape or sheet

A technology of pressure-sensitive adhesive tape and pressure-sensitive adhesive, which is applied in the medical and health field, can solve problems such as seepage, achieve the effect of eliminating print-through problems and enhancing viscosity recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

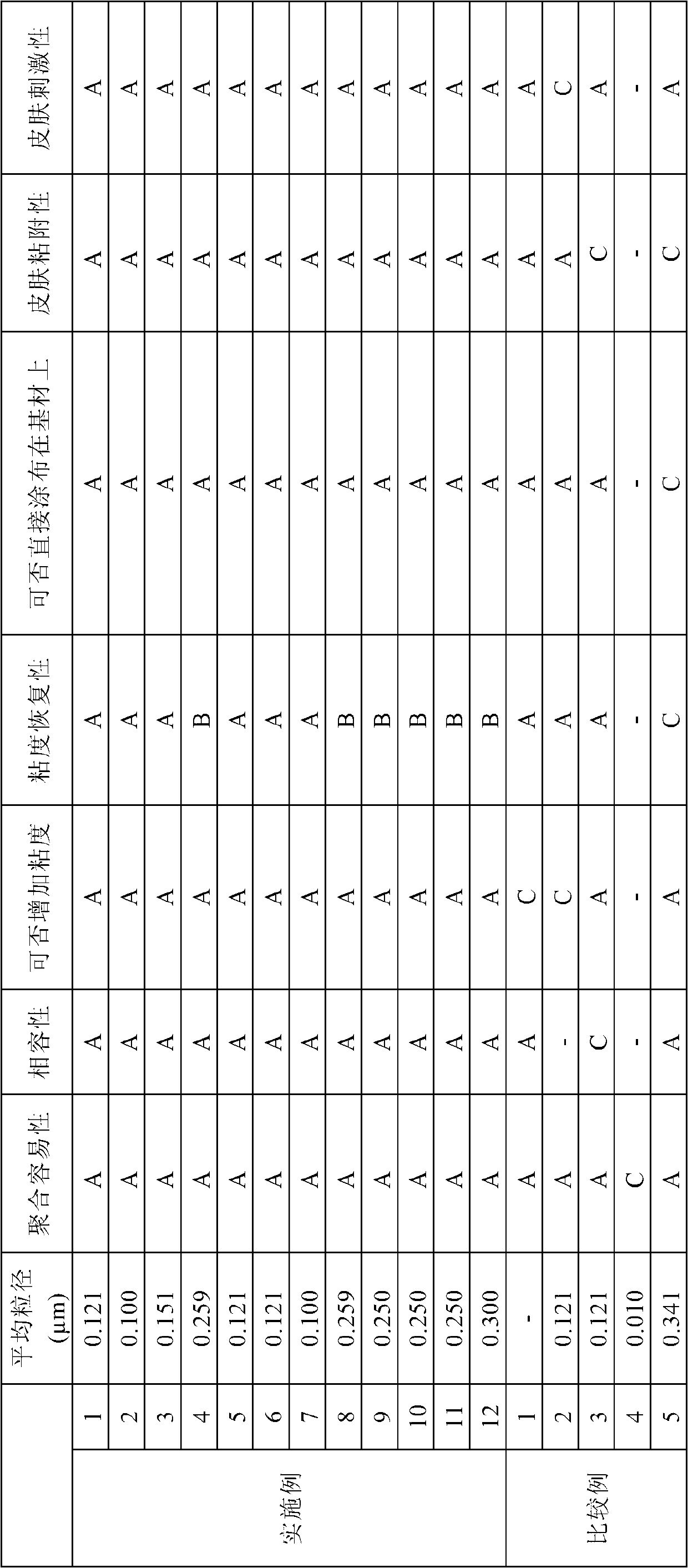

Examples

preparation example Construction

[0020] The alkyl (meth)acrylate (alkyl (meth)acrylate) used as the main component monomer in the step of preparing the monomer mixture for emulsion polymerization in the production method of the present invention is used for the pressure of the finally obtained The sensitive adhesive is an adhesive-imparting component, and an alkyl ester having an alkyl group having a carbon number of 1 or more and preferably 15 or less is used. Specific examples thereof include alkyl (meth)acrylates having a straight-chain or straight-chain alkyl group, such as methyl ester, ethyl ester, butyl ester, pentyl ester, hexyl ester, heptyl ester, octyl ester, nonyl ester, decyl ester, Undecyl and tridecyl esters. These can be used alone or in combination of two or more. Among them, n-octyl ester, isooctyl ester, 2-ethylhexyl ester, n-nonyl ester, and isononyl ester are preferably used from the viewpoint of exhibiting good pressure-sensitive adhesive properties as a medical pressure-sensitive adhes...

Embodiment 1

[0048]Add 0.03 parts by weight of 1 - dodecyl mercaptan, 2 parts by weight of polyoxyethylene lauryl ether ammonium sulfate and 36 parts by weight of water, and then the whole solution was emulsified by a high-speed mixer to obtain a monomer emulsion.

[0049] Next, 4 parts by weight of monomer emulsion, 1 part by weight of polyoxyethylene lauryl ether ammonium sulfate and 46 parts by weight of water were charged into a reaction vessel equipped with a cooling pipe, nitrogen inlet pipe, thermometer and stirrer, and nitrogen was introduced While stirring the mixture for 1 hour. Subsequently, 0.1 part by weight of 2,2'-azobis[N-(2-carboxyethyl)-2-methylpropionamidine]hydrate was charged, and the reaction was allowed to proceed at 60°C for 1 hour. Then, 104 parts by weight of the monomer emulsion obtained above was continuously added dropwise over 4 hours to thereby perform emulsion polymerization, and the resulting solution was aged for 3 hours to obtain a water-dispersed copoly...

Embodiment 2

[0053] Except that the monomer mixture for emulsion polymerization in Example 1 was changed to include 100 parts by weight of 2-ethylhexyl acrylate, 4 parts by weight of acrylic acid and 0.02 parts by weight of 3-methacryloxypropyltrimethoxysilane The monomer mixture, and polyoxyethylene lauryl ether ammonium sulfate as an emulsifier is added to the monomer emulsion in an amount of 1 part by weight and added to the outside of the reaction vessel in 2 parts by weight, to be the same as in Example 1 The medical pressure-sensitive adhesive tape of the present invention is manufactured in a manner.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com