Silver palladium/packfong stratiform composite material and preparation method

A layered composite material and composite material technology, which is applied in the field of silver-palladium/zinc-nickel-nickel layered composite material and its preparation, can solve the problems of reducing the market competitiveness of materials, reducing mechanical properties, and cracking of the base layer, so as to improve the appearance quality and Effects of electrical contact performance, improvement of surface quality and performance, and good interface bonding strength

Active Publication Date: 2010-12-22

CHONGQING CHUANYI AUTOMATION

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, when the Zn in BZn volatilizes seriously, causing the Zn content in the Zn-rich layer to reach more than 13%, it may still have a bad influence on the performance of the composite material.

First of all, after a large amount of Zn in BZn volatilizes, it will cause poor Zn in the base layer and reduce its mechanical properties. Especially in the case of uneven distribution of BZn alloy components, severe volatilization of Zn will lead to cracks in the base layer; secondly, Zn on the surface of AgPd If the content is too high, the contact resistance of the brush will increase at the initial stage of operation, which will reduce the early performance of the micro-motor; thirdly, if the Zn content is too high, the corrosion resistance of the surface of the brush will be reduced, causing abnormal startup of the new motor (such as the increase of the starting current). Da et al.); Finally, the influence of Zn on the metallic luster of the AgPd surface caused some high-end users to doubt the performance of the AgPd / BZn layered composite material in the field of brushes, reducing the market competitiveness of the material

Therefore, some technologies have been developed to reduce the amount of Zn deposited, such as mechanical grinding, increasing the strength and frequency of the blowing furnace, etc., but these technologies either cause the loss of precious metal materials, or it is difficult to ensure the consistency of Zn content, so the practical value is not great

Some companies have reduced Zn volatilization by electroplating copper on the surface of BZn, but the technology of controlling Zn volatilization by preparing a metal nickel layer has not been reported yet.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

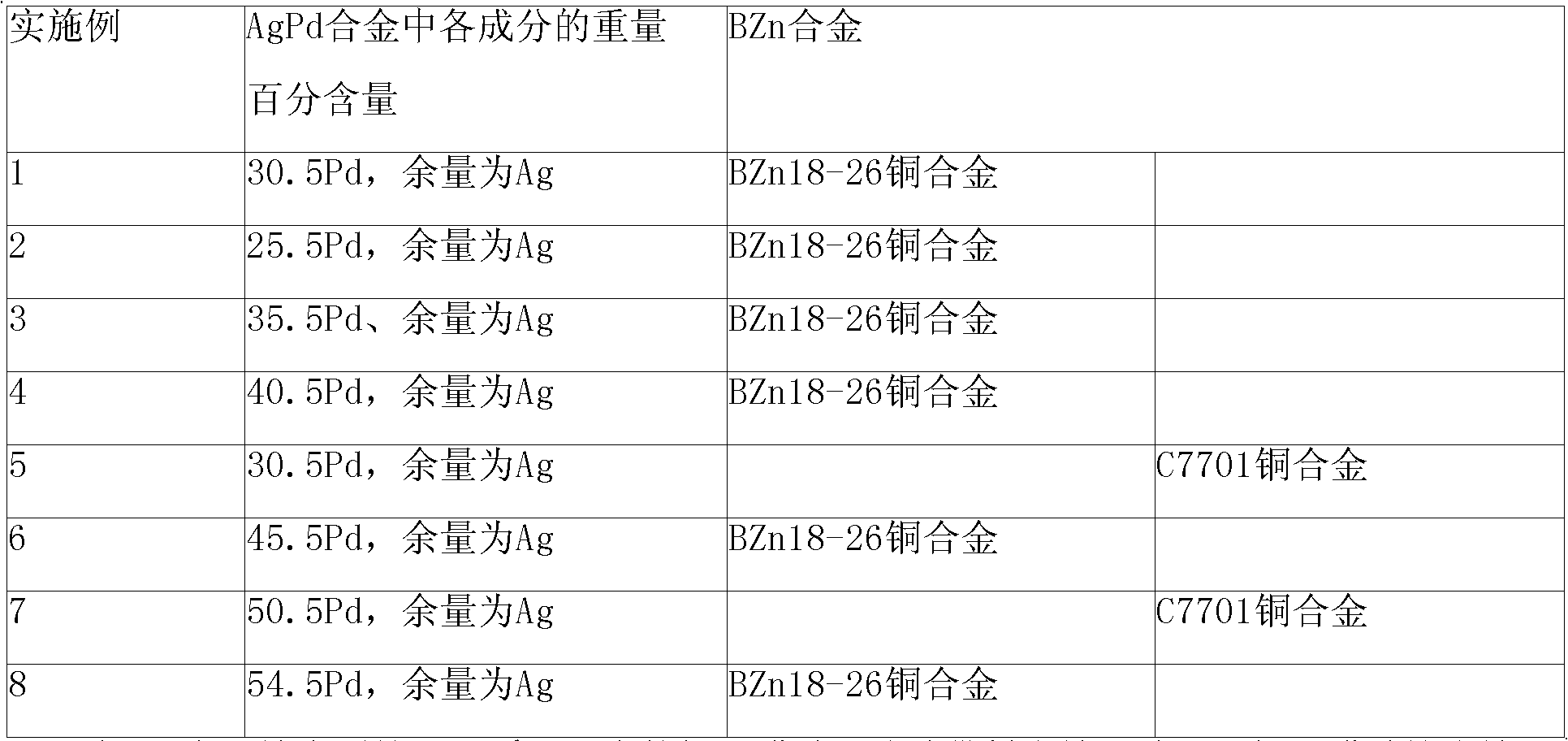

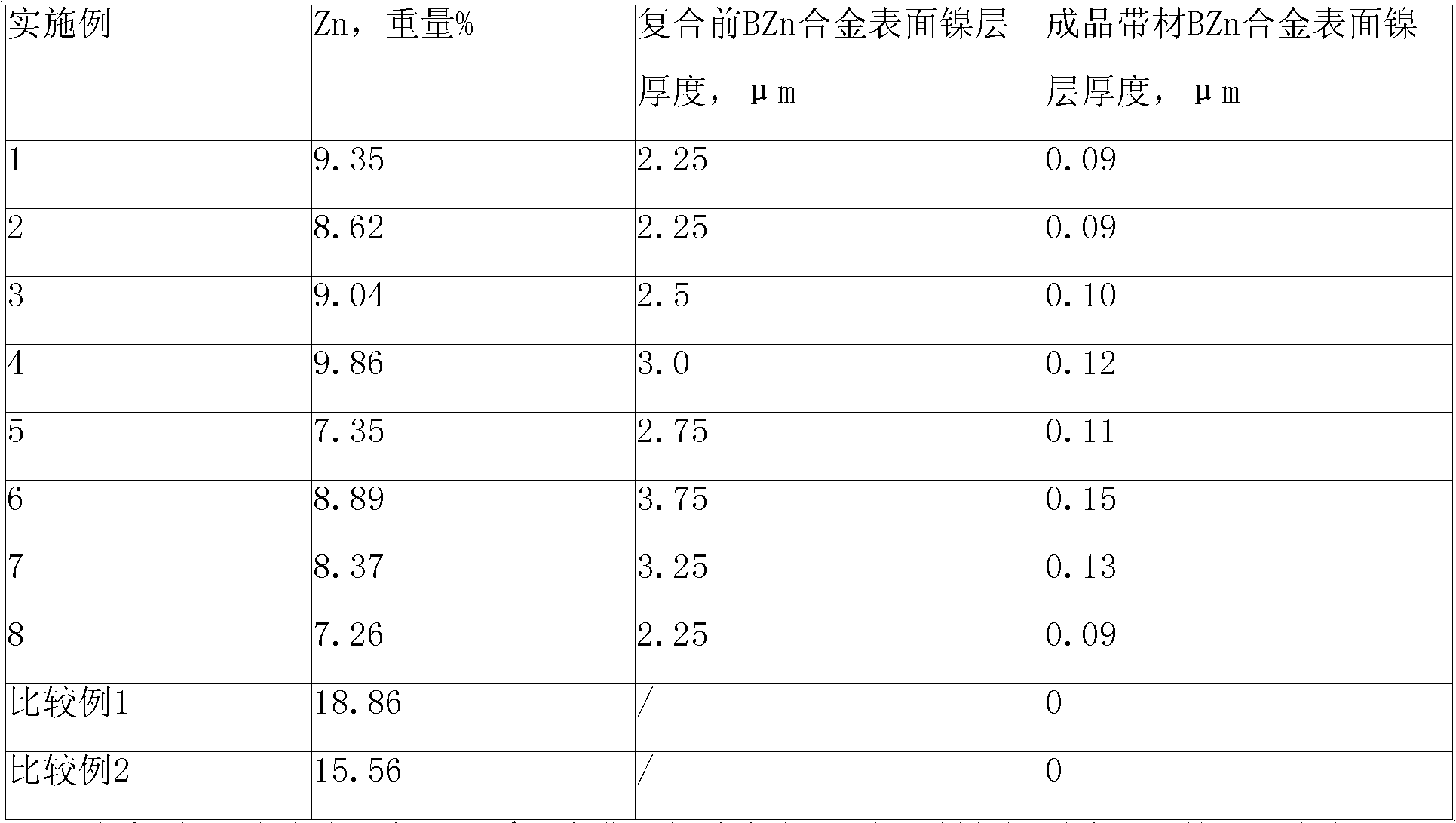

[0023] Get AgPd and BZn material in table 1, prepare silver-palladium / zinc-nickel-nickel layered composite material of the present invention according to the following process method:

[0024] Table 1

[0025]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a silver palladium / packfong stratiform composite material and a preparation method. The silver palladium / packfong stratiform composite material is characterized by being composed of a BZn alloy the surface of which is coated with metallic nickel and AgPd, wherein the AgPd is a work layer and the BZn is a basement layer. The preparation method of the material comprises thefollowing steps: adopting sulfamate continuous strip plating to plate a metal nickel layer on a BZn copper alloy surface; and carrying out hot rolled cladding on the AgPd alloy under the protection of nitrogen or hydrogen or the mixed gas of nitrogen and hydrogen. In the method of the invention, a metal nickel layer is plated on the BZn surface so as to control volatilization of Zn, thereby reducing deposition and enrichment of Zn on the surface of the AgPd layer, improving metal luster thereof, increasing initial usability of a brush material and satisfying requirements from high-end users.

Description

technical field [0001] The invention relates to a material used for a brush of a micro-motor, in particular to a silver-palladium / zinc-nickel-nickel layered composite material and a preparation method thereof. Background technique [0002] Silver-palladium alloy (hereinafter referred to as AgPd) has excellent electrical contact performance and corrosion resistance, and zinc white copper (copper-zinc-nickel alloy, hereinafter referred to as BZn) has excellent properties such as high strength and elasticity. The AgPd / BZn layer composed of the two Shaped composite material (AgPd is the working layer, BZn is the base layer, and the slash " / " between the two alloys indicates the interface between the two, the same below.) has the advantages of the above two aspects, so it is commonly used in micro motors brush material. This composite strip is produced by a hot-rolled clad process, or by a cold-rolled clad process, but it needs to experience high temperatures during the annealin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01R39/20H01R39/24H01R43/12C25D3/12B32B15/01

Inventor 杨贤军刘安利周晓荣赵明华徐永红章应

Owner CHONGQING CHUANYI AUTOMATION

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com