Method for preparing ergothioneine

A technology of ergothioneine and concentration, applied in the direction of organic chemistry, etc., can solve the problems of waste, low content of ergothioneine extract, difficulty in large-scale production, etc., achieve huge economic benefits, reduce production costs, reduce waste of resources and Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

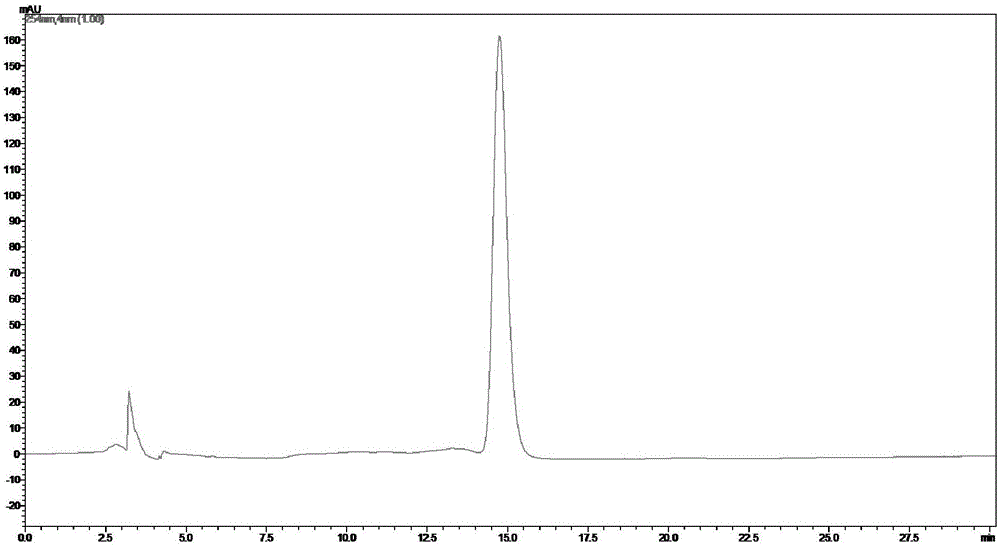

[0030] The conditions of the HPLC detection method for ergothioine:

[0031] Column: Kromasil 100-5NH 2 Column (250mm×4.60mm, E36056)

[0032] Detection wavelength: 254nm

[0033] Flow rate: 1.0ml / min

[0034] Column temperature: 30℃

[0035] Mobile phase: acetonitrile-5mmol / L ammonium acetate (80:20)

[0036] Injection volume: 20μL.

Embodiment 2

[0038] (1) Extraction: Add 500g of water to 100g of Hazel mushrooms, and extract 3 times at 95°C for 3, 2 and 1 hours of extraction time. Filter. The mesh number of the filter is 120. Combine the filtrate. Leave it to cool down until the temperature is lower than 50°C, discard the precipitate, and get the supernatant;

[0039] (2) Macroporous resin adsorption and separation: The supernatant obtained in (1) is adsorbed on HP20 type macroporous resin, water, and the volume percentage concentration is 5%, 15%, 25%, 35%, 50% ethanol aqueous solution Gradient elution, each 250ml is used as a receiving volume. Analytical HPLC is used to collect ergothioine-rich eluents, combine the eluents, and then under the condition that the temperature is ≤60℃ and the vacuum degree is 0.06~0.08MPa Concentrate under reduced pressure with a sugar content of 40 to obtain a macroporous resin separation product;

[0040] (3) Polyamide resin separation: disperse the macroporous resin separation product ob...

Embodiment 3

[0042] This embodiment includes four steps, among which steps (1) to (3) are the same as in embodiment 2, and step (4) operates as follows.

[0043] (4) ODS low-pressure column chromatography separation: the thioneine extract obtained by step (3) polyamide separation is adsorbed on ODS low-pressure column with water and the volume percentage concentration is 5%, 10%, 20%, 35 5% ethanol aqueous solution for gradient elution, each 25ml as a receiving volume, detected by analytical HPLC, with pure thioneine as the reference substance, collect the eluate rich in thioneine, and then at the temperature ≤60℃, Concentrate under reduced pressure under the condition of a vacuum degree of 0.06 to 0.08 MPa to obtain a concentrated thioneine product with a sugar content of 10. Measured by the method of Example 1, the content of ergothioneine is 80.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com