A<2>/O-BCO improvement process utilizing fermented sludge

An O-BCO, improved technology, applied in water/sludge/sewage treatment, biological sludge treatment, aerobic and anaerobic process treatment, etc., can solve the problem of unstable denitrification and phosphorus removal efficiency and low sewage treatment effect , the problem of high operating energy consumption, to achieve the effect of convenient management, alleviation of sludge disposal problems, and high biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

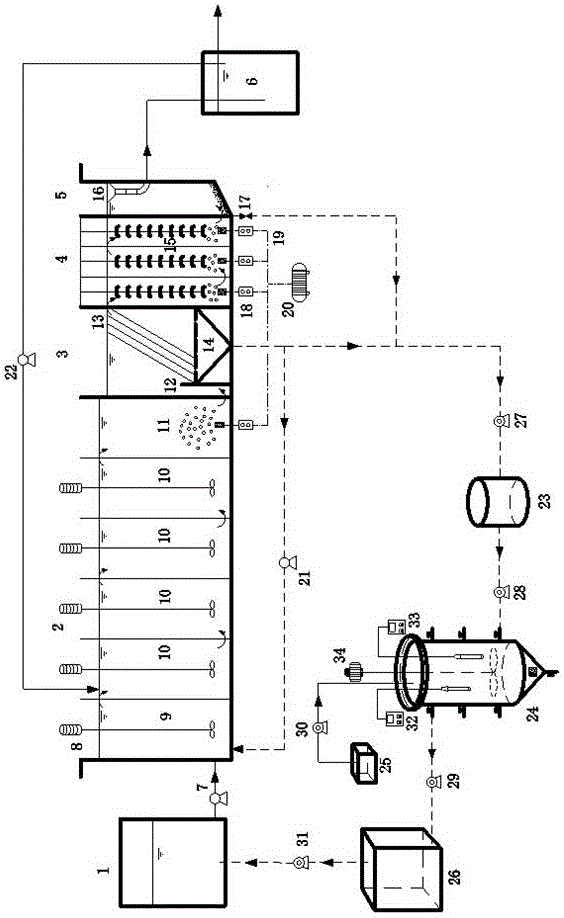

[0019] 1. Equipment introduction:

[0020] figure 1 Middle: 1-raw water tank; 2-A 2 / O reactor; 3- inclined plate sedimentation tank; 4-biological contact oxidation tank; 5-sedimentation area; 6-outlet water tank; 7-inlet pump; ;11-Aerobic zone; 12-Overflow baffle; 13-Inclined plate; 14-Sludge funnel; 15-Combined packing; 16-Overflow port; Air dry pipe; 20-blower; 21-sludge return pump; 22-nitration liquid return pump; 23-sludge storage tank; 24-fermentation tank; ; 28-lift pump II; 29-lift pump III; 30-lift pump IV; 31-lift pump V; 32-ORP tester; 33-pH tester; 34-fermentation tank stirring device.

[0021] A 2 / O reactor 2 includes anaerobic zone 9 , anoxic zone 10 and aerobic zone 11 .

[0022] A 2 The aerobic zone 11 of the / O reactor 2 is connected with the inclined plate sedimentation tank 3 through the overflow baffle 12, and the effluent is connected with the biological contact oxidation tank 4.

[0023] The biological contact oxidation tank 4 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com