Attapulgite-reinforced resin solid acid catalyst and preparation method thereof

The technology of solid acid catalyst and attapulgite is applied in the field of chemical industry, which can solve the problems of easy swelling and deactivation of mechanical properties, and achieve the effect of good anti-swelling performance and high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: This embodiment illustrates the method for synthetic solid acid catalyst

[0041] Using attapulgite and other raw materials, the solid acid catalyst was synthesized in the following steps.

[0042] (1) Modification of attapulgite

[0043] Add 3g of attapulgite to 150mL of toluene, add 1mL of deionized water and 0.1g of γ-(methacryloyloxy)propyltrimethoxysilane successively while stirring continuously, and react at 60°C for 14h. The modified attapulgite was washed repeatedly with ethanol, filtered, and then vacuum-dried at 60°C for 12 hours.

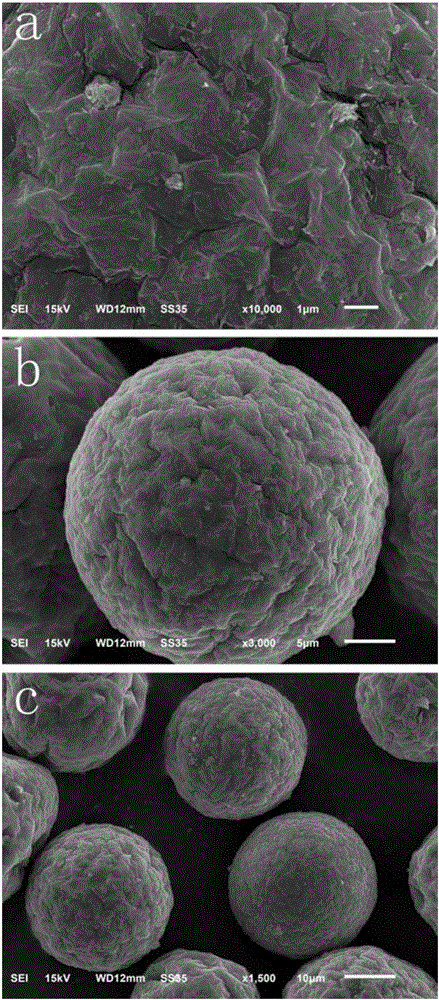

[0044] (2) Synthesis and sulfonation of attapulgite / polystyrene microspheres

[0045]Disperse 0.5g of the modified attapulgite in 120mL of deionized water, mix 1mL of divinylbenzene, 4mL of styrene and 0.3g of benzoyl peroxide, and add it to the suspension of attapulgite, homogenize Machine shaking for 30s, then poured into a 250mL three-neck flask, the reaction temperature was 70°C, and polymerized under mechanica...

Embodiment 2

[0052] Embodiment 2: This embodiment illustrates the method for synthetic solid acid catalyst

[0053] Using attapulgite and other raw materials, the solid acid catalyst was synthesized in the following steps.

[0054] (1) Modification of attapulgite

[0055] Add 3g of attapulgite to 150mL of toluene, add 1mL of deionized water and 0.1g of γ-(methacryloyloxy)propyltrimethoxysilane successively while stirring continuously, and react at 70°C for 12h. The modified attapulgite was washed repeatedly with ethanol, filtered, and then vacuum-dried at 60°C for 12 hours.

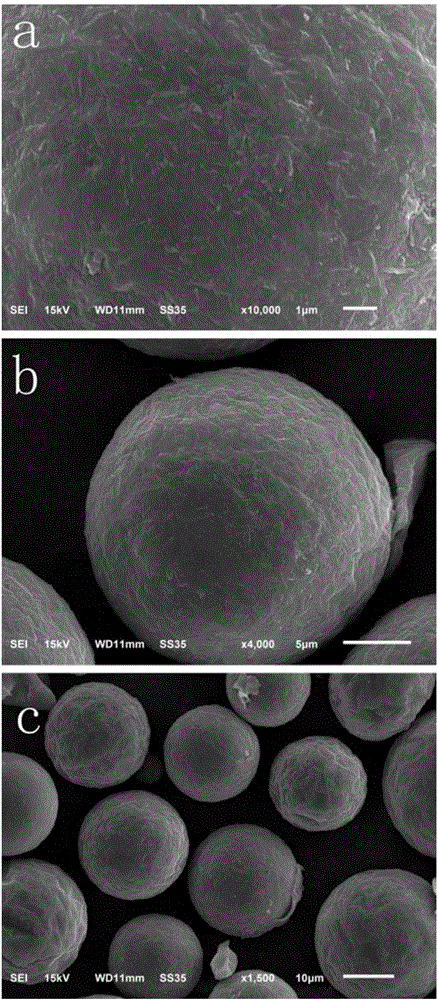

[0056] (2) Synthesis and sulfonation of attapulgite / polystyrene microspheres

[0057] Disperse 1 g of the modified attapulgite in 120 mL of deionized water, mix 1 mL of divinylbenzene, 4 mL of styrene and 0.3 g of benzoyl peroxide, add it to the suspension of attapulgite, and homogenize Shake for 30s, then pour into a 250mL three-necked flask, and polymerize for 7h under mechanical stirring at a reaction temperatur...

Embodiment 3

[0063] Embodiment 3: This embodiment illustrates the method for synthetic solid acid catalyst

[0064] Using attapulgite and other raw materials, the solid acid catalyst was synthesized in the following steps.

[0065] (1) Modification of attapulgite

[0066] Add 3g of attapulgite to 150mL of toluene, add 1mL of deionized water and 0.1g of γ-(methacryloyloxy)propyltrimethoxysilane successively while stirring continuously, and react at 80°C for 10h. The modified attapulgite was washed repeatedly with ethanol, filtered, and then vacuum-dried at 60°C for 12 hours.

[0067] (2) Synthesis and sulfonation of attapulgite / polystyrene microspheres

[0068] Disperse 1.5g of modified attapulgite in 120mL of deionized water, mix 1mL of divinylbenzene, 4mL of styrene and 0.3g of benzoyl peroxide, and add it to the suspension of attapulgite, homogenize Machine shaking for 30s, then poured into a 250mL three-neck flask, the reaction temperature was 60°C, and polymerized under mechanical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com