Oxiracetam oral preparation and preparation method thereof

Another, oral instant film technology, applied in the field of oxiracetam oral preparations and its preparation, can solve the problems of complex development and production process, coalescence of solid particles, self-administration by patients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

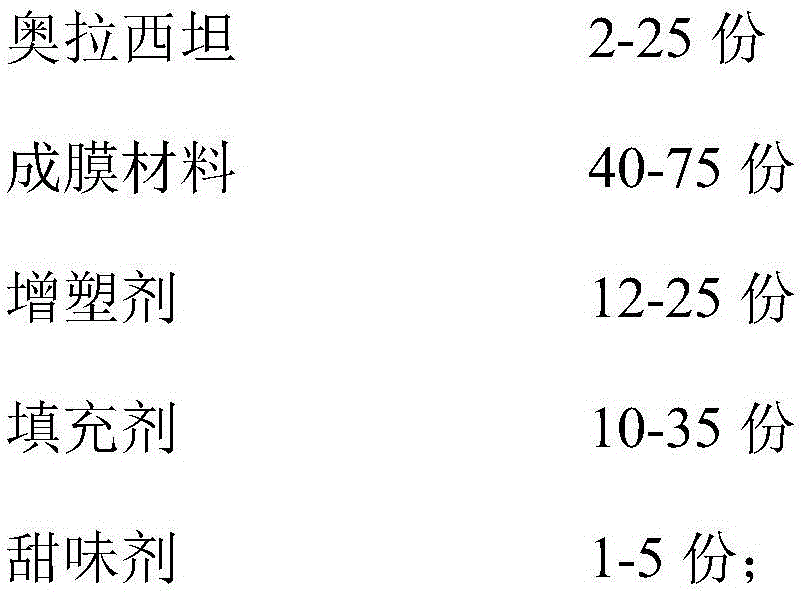

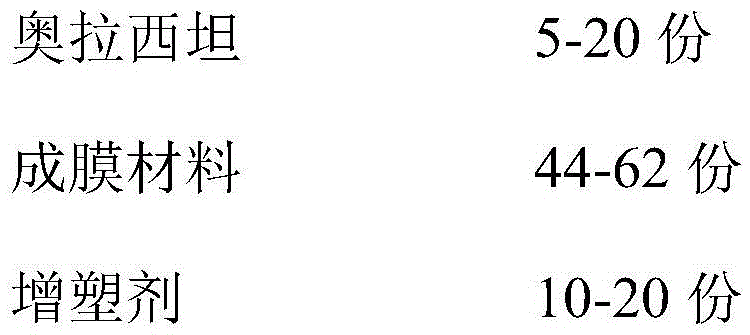

Method used

Image

Examples

Embodiment 1

[0089] The preparation of oxiracetam film adopts the following steps:

[0090] 1) Dissolve 58g of film-forming material (acrylic acid ester and hydroxypropyl methylcellulose, wherein the dosage of hydroxypropylmethylcellulose is 30g) with 80mL of deionized water, and remove air bubbles to obtain a uniform viscous liquid;

[0091] 2) Disperse 18g of dibutyl phthalate, 15g of microcrystalline cellulose and 2g of xylitol with 50mL of deionized water to form a dispersion;

[0092] 3) Add the dispersion of step 2) to the viscous liquid of step 1), and add 7g of oxiracetam to disperse evenly, and then let it stand to remove air bubbles;

[0093] 4) Coat the viscous liquid after removing air bubbles with a drug film coating dryer at a coating speed of 50cm / min, then dry at 65-68°C, peel off and cut.

Embodiment 2

[0095] The preparation of oxiracetam film adopts the following steps:

[0096] 1) Dissolve 50g of film-forming material (acrylic acid ester and hydroxypropyl methylcellulose, wherein the dosage of hydroxypropylmethylcellulose is 10g) with 50mL of deionized water, and remove air bubbles to obtain a uniform viscous liquid;

[0097] 2) Disperse 12g triacetin, 20g low-substituted hydroxypropyl cellulose and 1g acesulfame potassium with 60mL deionized water to form a dispersion;

[0098] 3) Add the dispersion of step 2) to the viscous liquid of step 1), and add 17g of oxiracetam to disperse evenly, and then let it stand to remove air bubbles;

[0099] 4) Coat the viscous liquid after removing air bubbles with a drug film coating dryer at a coating speed of 80cm / min, then dry at 70-72°C, peel off and cut.

Embodiment 3

[0101] The preparation of oxiracetam film adopts the following steps:

[0102] 1) Dissolve 50g of film-forming material (acrylic acid ester and hydroxypropyl methylcellulose, wherein the dosage of hydroxypropylmethylcellulose is 20g) with 50mL of deionized water, and remove air bubbles to obtain a uniform viscous liquid;

[0103] 2) Disperse 15g of trimethyl citrate, 15g of microcrystalline cellulose and 5g of aspartame with 40mL of deionized water to form a dispersion;

[0104] 3) Add the dispersion of step 2) to the viscous liquid of step 1), and add 15g of oxiracetam to disperse evenly, then let it stand to remove air bubbles;

[0105] 4) Coat the viscous liquid after removing air bubbles with a drug film coating dryer at a coating speed of 70cm / min, then dry at 80-85°C, peel off and cut.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com