A copper-based ternary composite metal oxide hollow nanomaterial, preparation method and application

A ternary composite and hollow nanotechnology, which is applied in the preparation of amino hydroxyl compounds, the preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, etc. High economic cost and other problems, to achieve the effect of easy scale-up experiment, low production cost, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

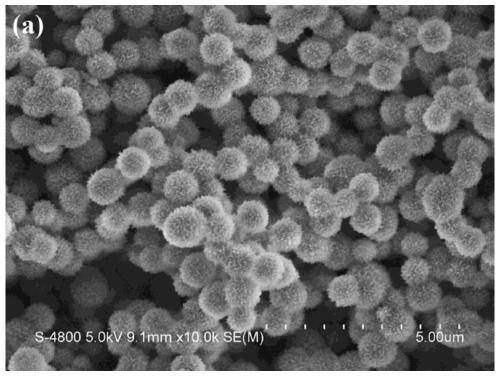

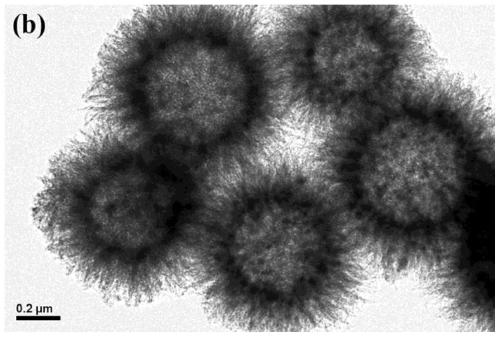

[0043] A method for preparing copper-based ternary composite metal oxide hollow nanomaterials, comprising the following steps:

[0044] A. Mixing: At room temperature, add 0.2416g copper nitrate trihydrate and 0.2908g nickel nitrate hexahydrate to 30ml of a mixed solvent of ethylene glycol and water with a volume ratio of 1:2, and add 0.6g urea and 0.5g poly Vinylpyrrolidone, fully stirred to make a homogeneous solution;

[0045] B, heating: the solution prepared in step A is heated to 90 ℃, and the reaction time is 10 hours;

[0046] C. Drying: Cool the precipitate heated in step B, transfer it to a beaker after ultrasonication, centrifuge the mother liquor, wash it with water, wash it with alcohol, and dry it in vacuum at 60°C to constant weight to obtain hollow Cu- Ni precursor material;

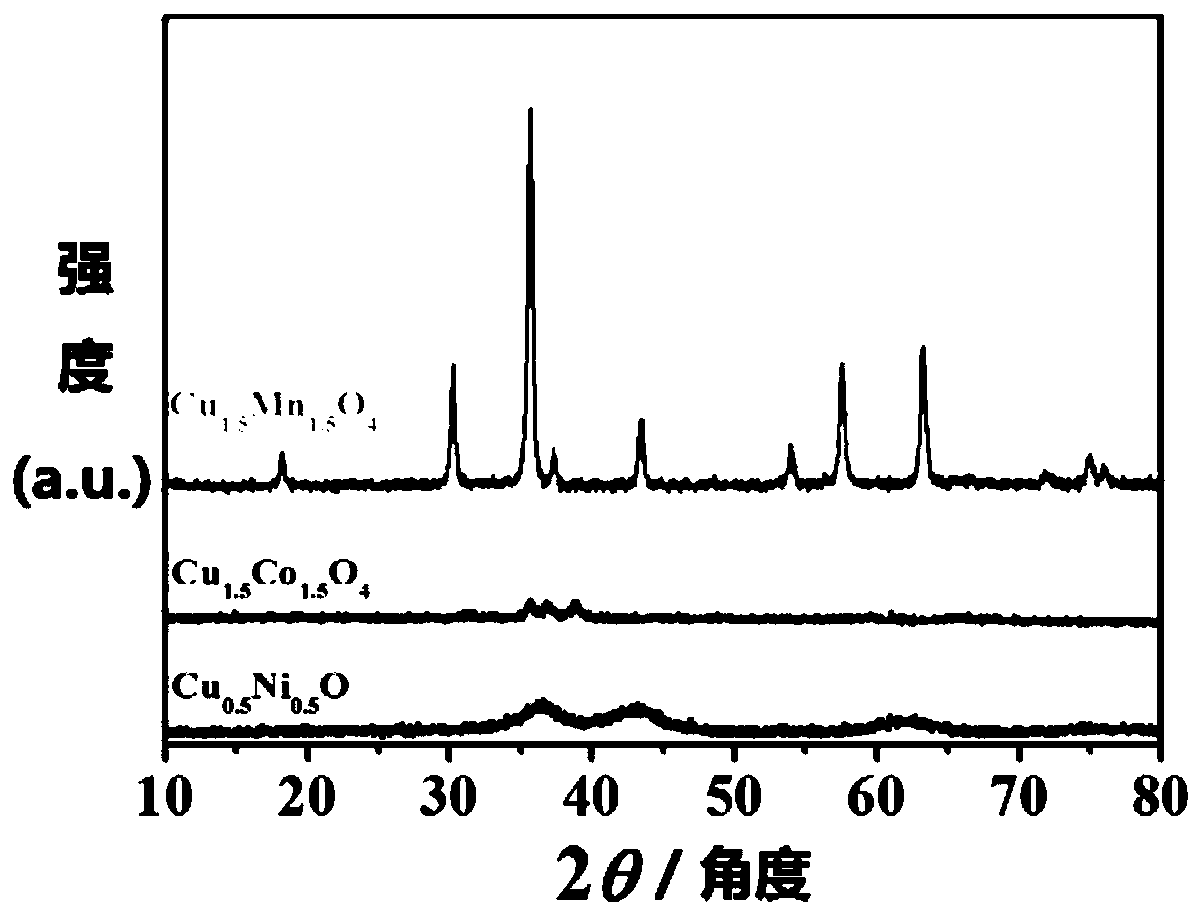

[0047] D. Calcination: place the dried product obtained in step C to calcine at a temperature of 300°C in an air environment. The calcination time is 5 hours. The calcination does not r...

Embodiment 2

[0052] A method for preparing copper-based ternary composite metal oxide hollow nanomaterials, comprising the following steps:

[0053] A. Mixing: At room temperature, add 0.242g copper nitrate trihydrate and 0.146g cobalt nitrate hexahydrate to 30ml of a mixed solvent of ethylene glycol and water with a volume ratio of 1:2, and add 0.6g urea and 0.5g poly Vinylpyrrolidone, fully stirred to make a homogeneous solution;

[0054] B, heating: the solution prepared in step A is heated to 90 ℃, and the reaction time is 10 hours;

[0055] C. Drying: Cool the precipitate heated in step B, transfer it to a beaker after ultrasonication and let it stand still, centrifuge the mother liquor, wash it with water and alcohol, and dry it in vacuum at 60°C to constant weight to obtain a hollow Cu-Co precursor body material;

[0056] D. Calcination: place the dry product obtained in step C for calcination at a temperature of 400° C. in an air environment for 5 hours. The calcination does not ...

Embodiment 3

[0061] A method for preparing copper-based ternary composite metal oxide hollow nanomaterials, comprising the following steps:

[0062] A. Mixing step: at room temperature, add 0.120ml of manganese nitrate (50% by mass fraction) solution and 0.242g of copper nitrate trihydrate to 30ml of a mixed solvent of ethylene glycol and water with a volume ratio of 1:2, and Add 1.2g urea and 0.5g polyvinylpyrrolidone, stir well to make a uniform solution;

[0063] B, heating step: the solution prepared in step A is heated to 90 ℃, and the reaction time is 10 hours;

[0064] C. Drying step: Cool the precipitate heated in step B, transfer it to a beaker after ultrasonication and let it stand still, centrifuge the mother liquor, wash it with water and alcohol, and dry it in vacuum at 50°C to constant weight to obtain hollow Cu-Mn Precursor;

[0065] D. Calcination step: place the dried product obtained in step C to calcine at a temperature of 550° C. in the air environment for 5 hours, wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com