High temperature and high pressure resistant alkali-free aluminosilicate glass for high pressure liquidometer

A high-pressure liquid, high-temperature-resistant technology, used in glass forming, glass furnace equipment, glass manufacturing equipment, etc., can solve the problems of low softening point, poor chemical stability, low Young's modulus, etc., to achieve uniform electric field heat distribution, The effect of uniform distribution of electric field lines and smooth melting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0028] The oxide composition and mass percentage of the alkali-free aluminosilicate glass of the high-temperature and high-pressure resistant high-pressure liquid level gauge are: SiO 2 (55~65)%, Al 2 o 3 (14~25)%, B 2 o 3 (3~8)%, CaO(5~12)%, MgO(4~10)%, BaO(3~8)%, As 2 o 3 (0.2~0.5)%, Sb 2 o 3 (0.2~0.5)%, NaNO 3 (0.1~0.3)%, ZrO 2 (0.2~0.5)%, adopt following technological process experiment and implement:

[0029] First of all, select the glass raw material to make it into the above-mentioned characteristic glass composition, configure it, mix it evenly, and melt it in the pool platinum electric furnace. Or cast into various wafer blanks, which are processed by precision annealing, grinding, polishing and tempering. The result obtained by above-mentioned technical process experiment:

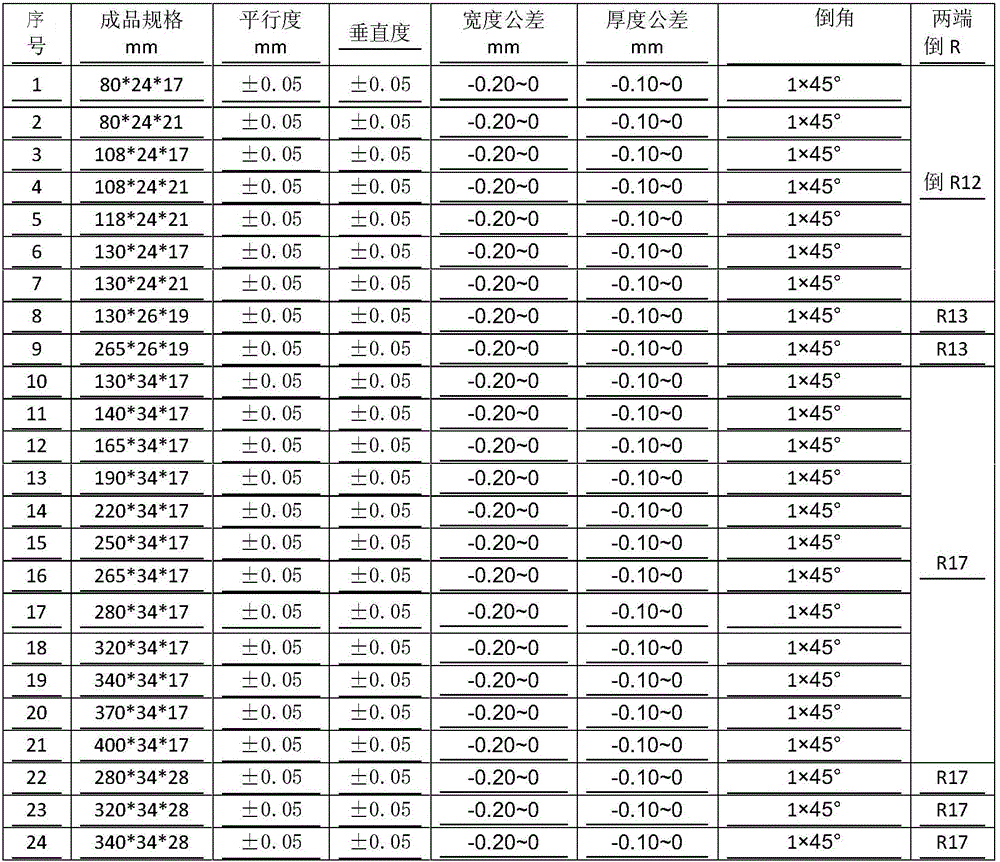

[0030] Table 1, chemical composition (wt.%) and glass performance table of experimental example:

[0031] composition Experimental example 1 Experimental example 2 Exp...

Embodiment 1

[0044] The tempering temperature is preferably 900°C, and the fan flow rate is preferably 15000m 3 / h.

[0045] First of all, according to Table 1 Experimental Example 1 glass component selection main raw material requirements, use quartz sand (150 μm sieve is less than 1%, 45 μm sieve is less than 30%, Fe 2 o 3 content less than 0.01wt.%), calcined alumina (average particle size 50μm), boric acid (400μm sieve is less than 10%, 63μm sieve is less than 10%), high-purity calcium carbonate (average particle size 250μm), high Pure magnesium oxide (average particle size 250 μm), barium carbonate (average particle size 50 μm). Fe in glass raw materials 2 o 3 Carry out strict control, requiring less than 100PPm, finished glass Fe 2 o 3 Less than 150PPm. The clarifying agent uses a variety of clarifying agent raw materials to make the ingredients meet the chemical composition of the glass in Table 1, and then melts it in an all-electric furnace with high thermal efficiency. Afte...

Embodiment 2

[0047] The tempering temperature is preferably 900°C, and the fan flow rate is preferably 15000m 3 / h.

[0048] For the actual composition of the glass, refer to Experimental Example 2 in Table 1, use the same raw materials and requirements as in Example 1, and adopt the same melting process system and test conditions. Table 1 shows the basic properties of the samples. (1) The density is 2.62g / cm 3 ; (2) The average coefficient of thermal expansion within the range of room temperature to 400°C is 45.89×10 -7 / °C; (3) softening temperature (10 5 ~10 7 Poise) 921°C; (4) Bending strength 258Mpa; (5) Transmittance 90.3% (6) Refractive index N d 1.5332 Young's modulus E (10 7 pa)8290

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com