Stepping type power ultrasonic strong pulse scale preventing and removing device and control method

An anti-scaling and descaling, ultrasonic technology, applied in the direction of using vibrating fluid, etc., can solve problems such as unsatisfactory anti-scaling and descaling effect, improper selection of components, performance parameters that do not meet control requirements, etc. Failure rate, fast scaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] A step-by-step power ultrasonic strong pulse anti-scaling and descaling device includes a main circuit part, a control unit part and a power supply part.

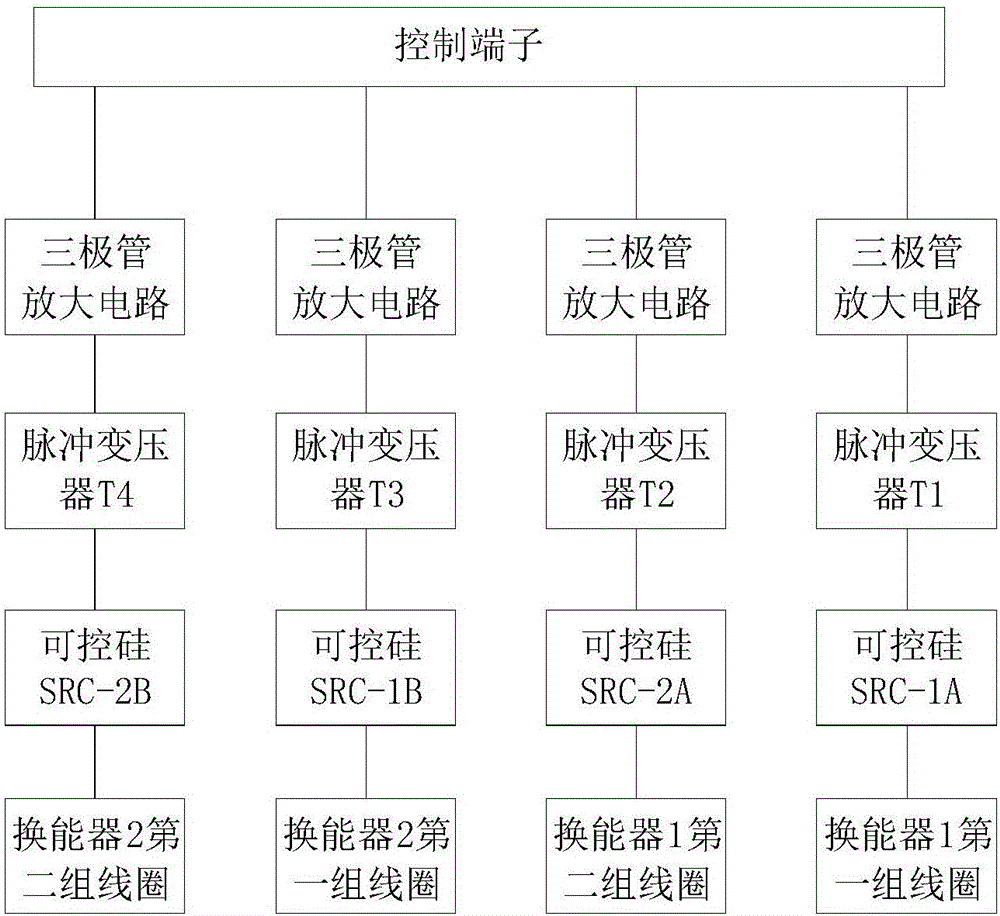

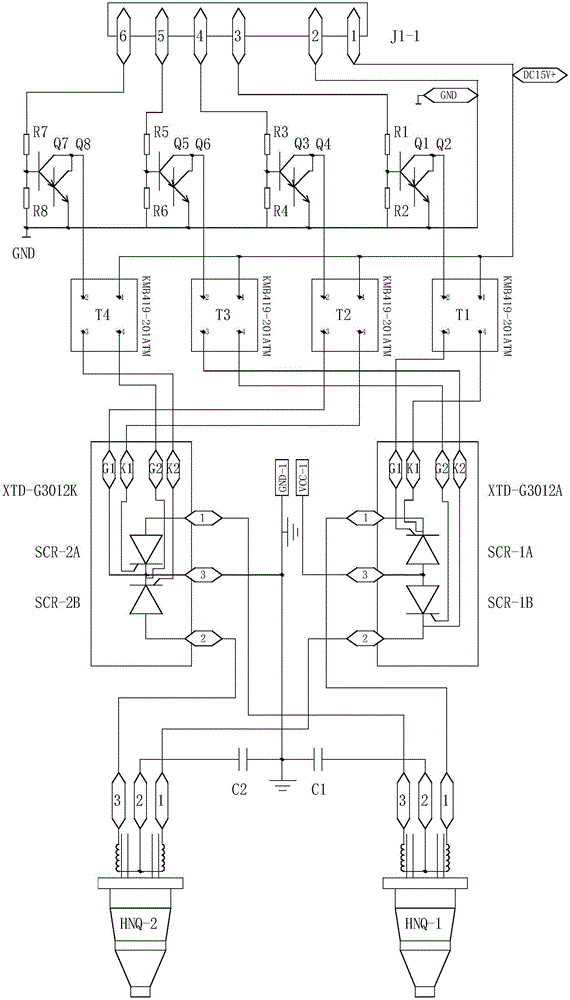

[0032] like figure 1 As shown, the main circuit part includes triode amplifier circuit, pulse transformer, thyristor, capacitor and transducer; The output end of the trigger signal sent by the control unit is connected to the input end of the pulse transformer, and the output end of the pulse transformer is connected to the trigger end of the thyristor.

[0033] like figure 2 As shown, the SCR trigger main circuit is divided into 4 circuits. The first triode amplifier circuit on the right is composed of transistors Q1 and Q2. Pin 3 of the input terminal is connected to the input terminal of the triode amplifier circuit through R1, and the output terminal is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com