Externally-mounted sub-spindle

A plug-in, spindle technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of low demand for linear motor machine tools, small market demand, and high equipment cost, etc., to achieve Solve the accuracy requirements and efficiency problems, easy to adjust and control, and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

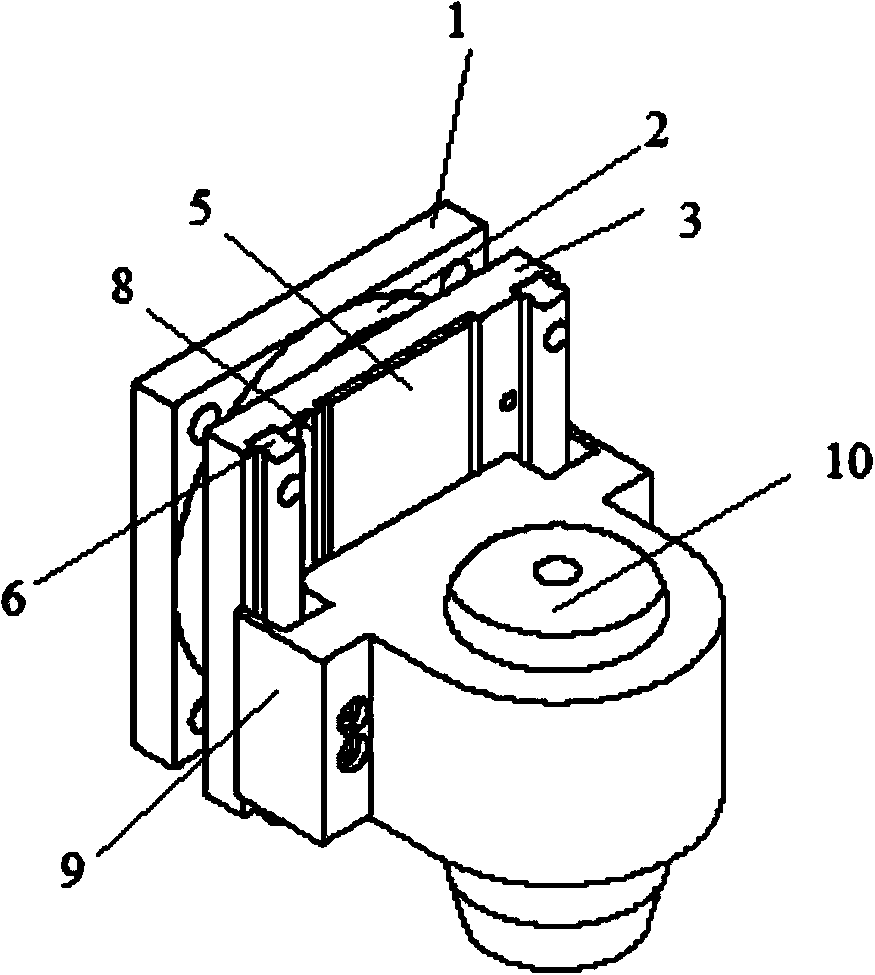

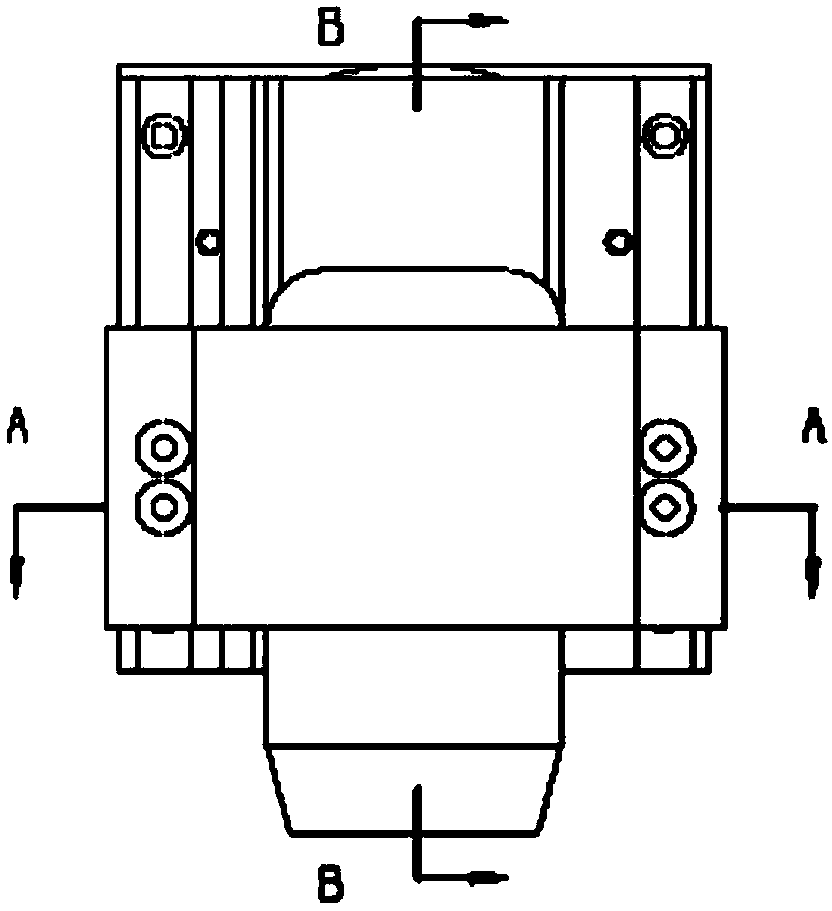

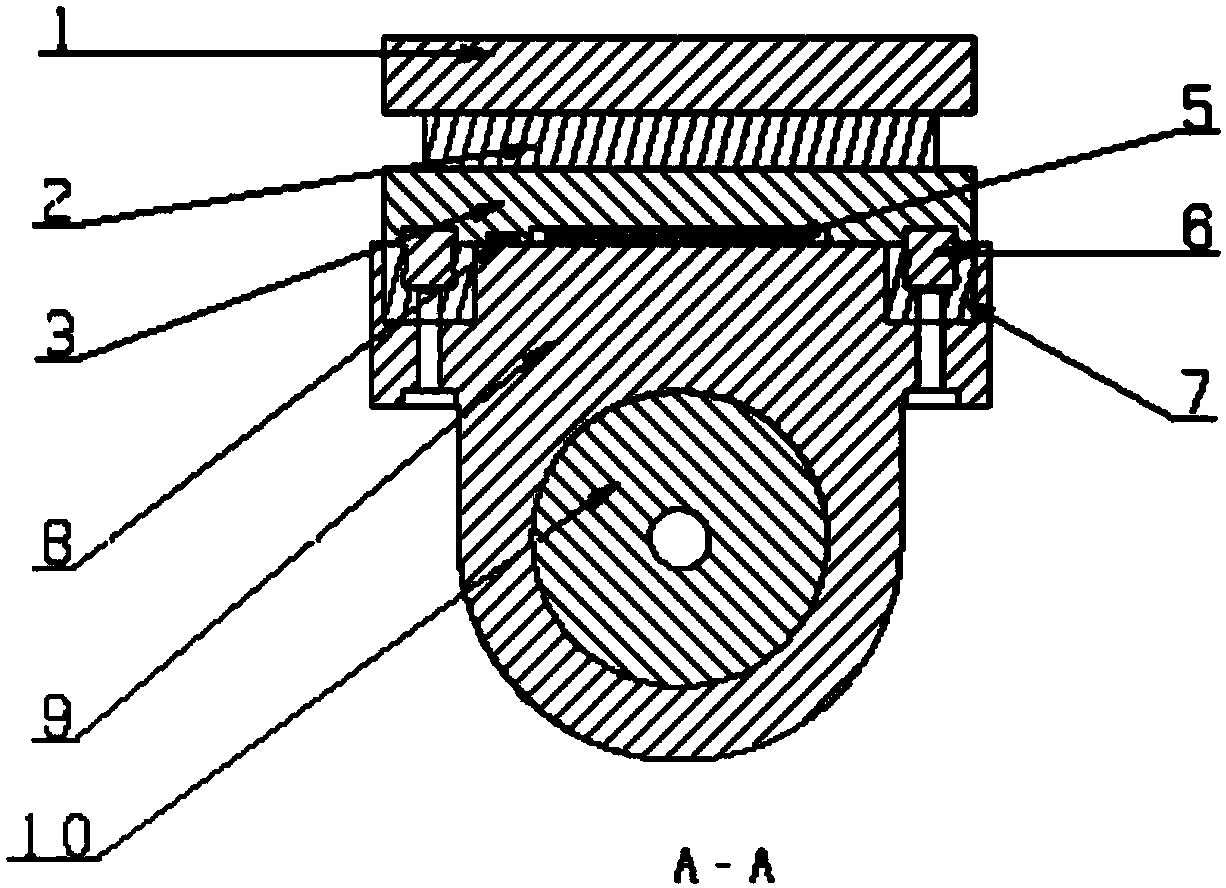

[0032] Such as Figure 1-5 As shown, an externally mounted sub-spindle can be used alone or in conjunction with traditional mechanical equipment, for example, through the Z-axis screw drive movement of the CNC machine tool itself or equipped with a linear motor for independent movement. In this embodiment, the external sub-spindle is used in combination with a CNC machine tool. The CNC machine tool includes a machine bed 101, a workbench 102 and a main shaft 103. The external sub-spindle 104 is installed on the main shaft 103 of the CNC machine tool. The external hanging sub-spindle 104 includes a fixed connection plate 1, an adjustable index plate 2, a sliding backing plate 3, a precision guide rail 6, a linear slider 7, a main shaft mounting seat 9, and a high-speed main shaft 10; The connecting plate 1 is fixed on the main shaft 103 by bolts or magnetic force. The adjustable indexing plate 2 and the sliding backing plate 3 are sequentially arranged on the installation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com