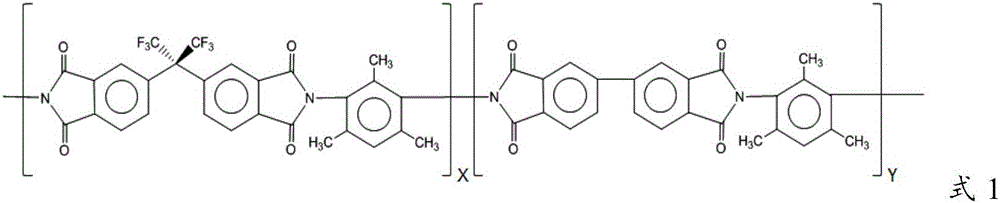

Carbon molecular sieve (cms) hollow fiber membranes and preparation thereof from pre-oxidized polyimides

A technology made of carbon molecular sieve membrane and polyimide is applied in the field of hydrogen separation CMS, which can solve the problems of increasing the thickness of the separation layer and reducing the permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

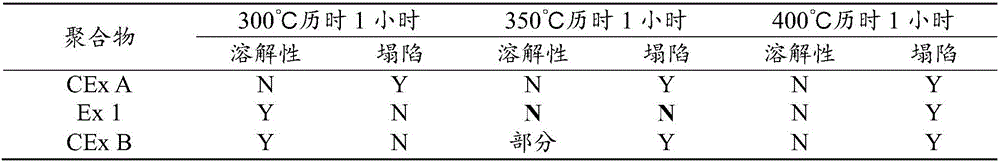

[0025] Example (Ex) 1, comparative example (CEx) A and CEx B

[0026] Defect-free Matrimid, 6FDA-DAM and 6FDA / BPDA-DAM precursor fibers were formed by dry jet / wet quench fiber spinning method. The fiber spinning setup and conditions are described in "Olefins-selective asymmetric carbon molecular sieve hollow fiber membranes for hybrid membrane- distillation processes for olefin / paraffin separations), Journal of Membrane Science (423-424 (2012), pp. 314-323). In that approach, the polymer precursor was first dried overnight in a vacuum oven operated at a set point temperature of 110°C to remove moisture and residual organics. The spinning dope was prepared as follows: at room temperature by sealed Glass vials were placed on a roller to form a visually homogeneous polymer solution (Matrimid TM =26.2wt% polymer, 53wt% N-methyl-2-pyrrolidone (NMP), 14.9wt% ethanol (EtOH) and 5.9wt% tetrahydrofuran (THF); 6FDA-DAM=22wt% polymer, 43wt% NMP, 25 wt% EtOH, 10 wt% THF; and 6FDA / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com