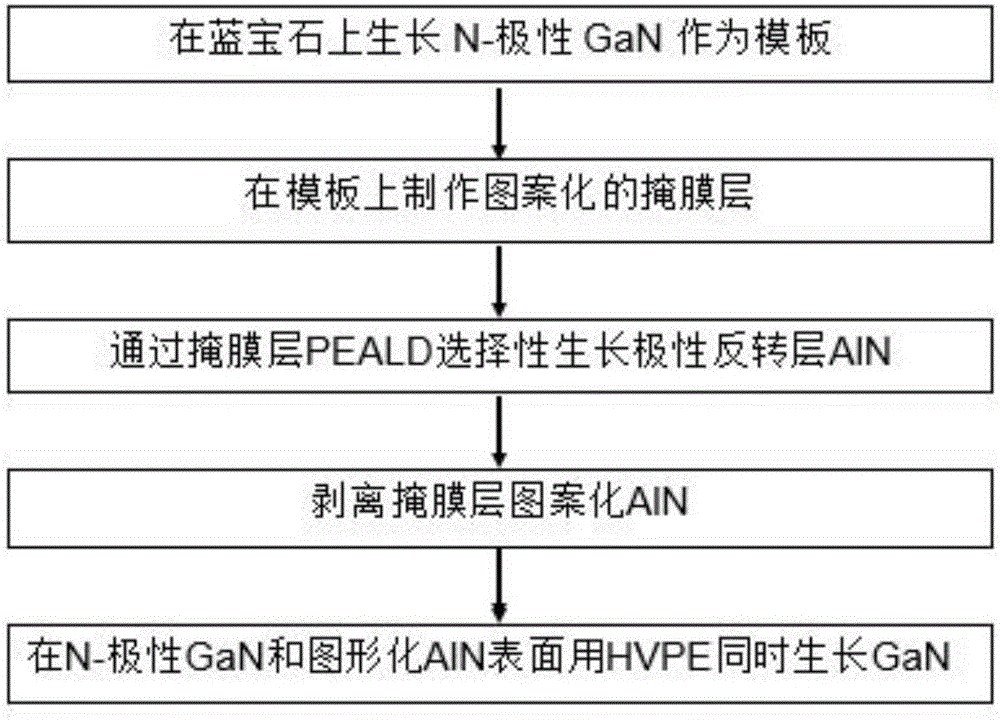

Method for growing polarity alternate GaN structure on N-polar GaN template

A technology of growing polarity and polarity, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of high cost of GaN substrates and difficult popularization of GaN structures, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Methods for growing alternating Ga- and N-polar GaN structures on sapphire substrates:

[0050] Step 1: Clean the sapphire substrate with isopropanol, acetone, methanol, alcohol, and deionized water at room temperature for 5 minutes, and finally wash it with N 2 blow dry.

[0051] Step 2: Put the cleaned sapphire substrate in the N-rich MOCVD reaction chamber, perform nitriding treatment at high temperature, and use triethylgallium TEG and NH 3 As Ga and N sources respectively, grow N-polar GaN with a film thickness of 1.5-2um under the conditions of a temperature of 1100°C, a chamber pressure of 150Torr, and a V / III ratio of 600-3000.

[0052] Step 3: Using N-polar GaN as a template, prepare a patterned photoresist by photolithography: soak the above sample in deionized water for 2 minutes, and then use 80°C standard cleaning solution SC1 (NH 4 0H:H 2 o 2 :H 2 (O=1:1:5) was cleaned for 10 minutes, then cleaned with deionized water and dried with nitrogen, and a la...

Embodiment 2

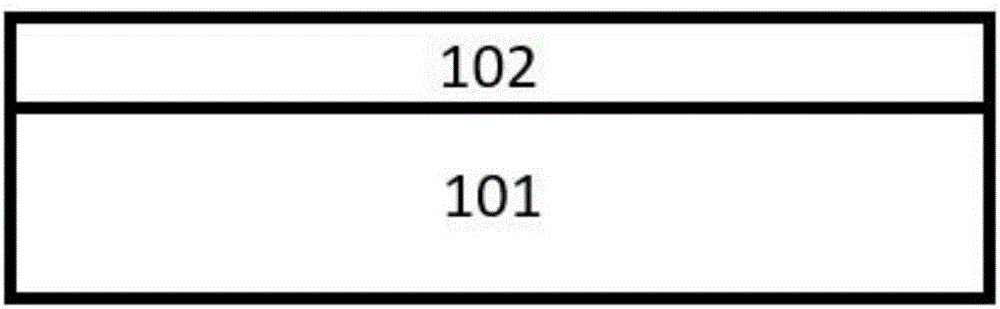

[0057] 1) Refer to figure 2 , the sapphire substrate 101 was ultrasonically cleaned with isopropanol, acetone, methanol, and alcohol at room temperature for 5 minutes, then repeatedly rinsed with deionized water, and washed with N 2 blow dry. The cleaned sapphire substrate 101 is placed in an N-rich MOCVD reaction chamber, and after nitriding treatment at high temperature, it is treated with triethylgallium TEG and NH 3 As Ga and N sources respectively, a 2um N-polar GaN layer 102 is grown under the conditions of a temperature of 1100° C., a chamber pressure of 150 Torr, and a V / III ratio of 3000.

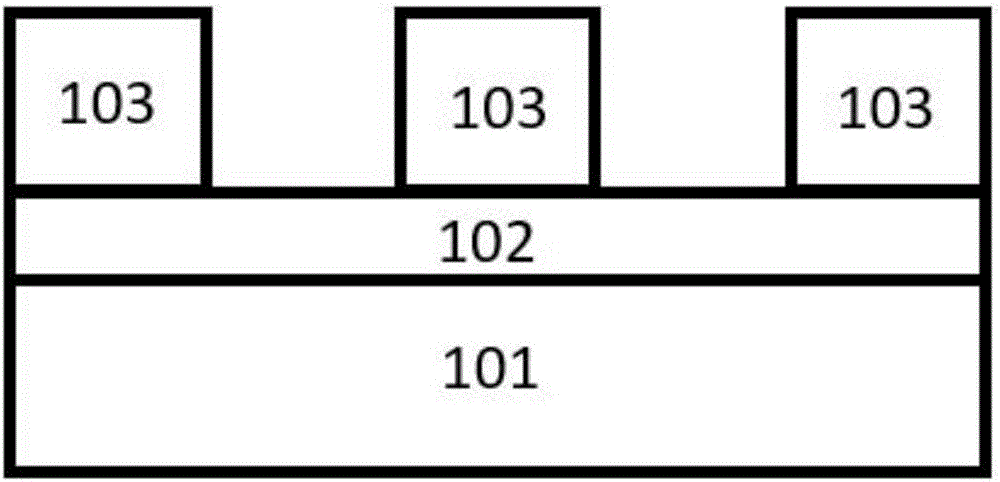

[0058] 2) Refer to image 3 , using N-polar GaN as a template, use a photolithography process to make a patterned photoresist 103: soak the sample in the previous step in deionized water for 2 minutes, and then use 80°C standard cleaning solution SC1 (NH40H: H2O2:H2O=1:1:5) was cleaned for 10 minutes, then cleaned with deionized water and dried with nitrogen, and a layer of pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com