Surface modification method of tungsten and aluminum composite material

A composite material and surface modification technology, applied in the direction of improving process efficiency, improving energy efficiency, etc., can solve problems such as low hardness, low material bonding force, and reduce surface quality, and improve wear resistance and corrosion resistance. , good density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for surface modification of a W / Al composite material, specifically comprising the steps of:

[0026] (1) First place the W / 2024Al composite material with a volume percentage of W of 5% in a high-frequency induction heating furnace, and adjust the position of the material in the high-frequency induction heating coil;

[0027] (2) Turn on the power of the equipment, vacuumize the induction heating furnace (less than 0.1Pa) or pass in an inert gas (argon or nitrogen, etc.) to protect the atmosphere;

[0028] (3) Set the frequency of induction heating to 10KHZ, start induction heating, each induction heating time is 5s, and continue the next induction heating after the pause time is greater than 10min, and conduct induction heating for a total of 5 times until the surface heating temperature reaches 600°C , to generate a dense protective layer of tungsten-aluminum intermetallic compound on the surface area of the material.

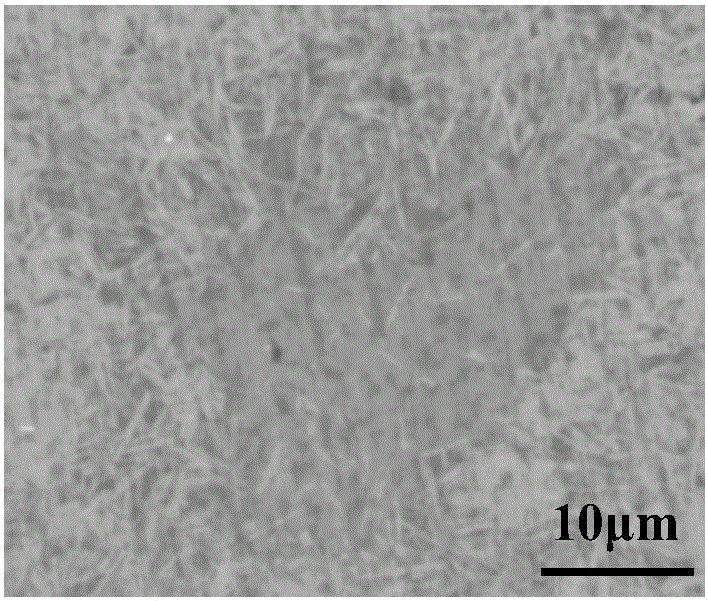

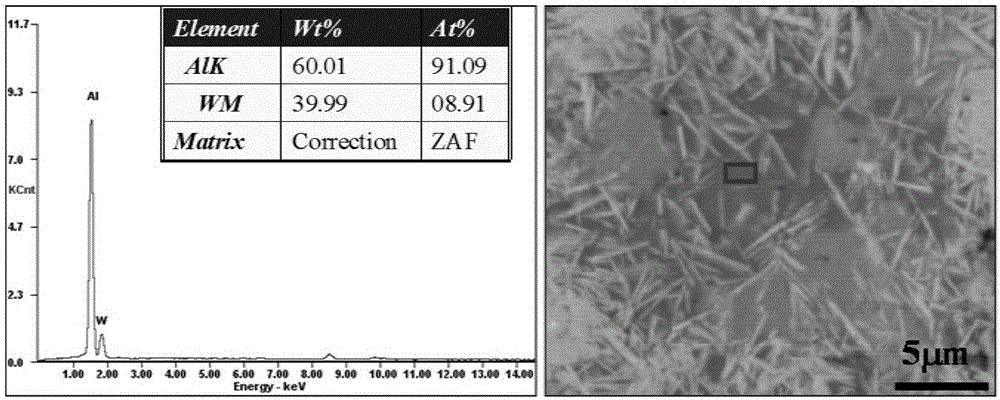

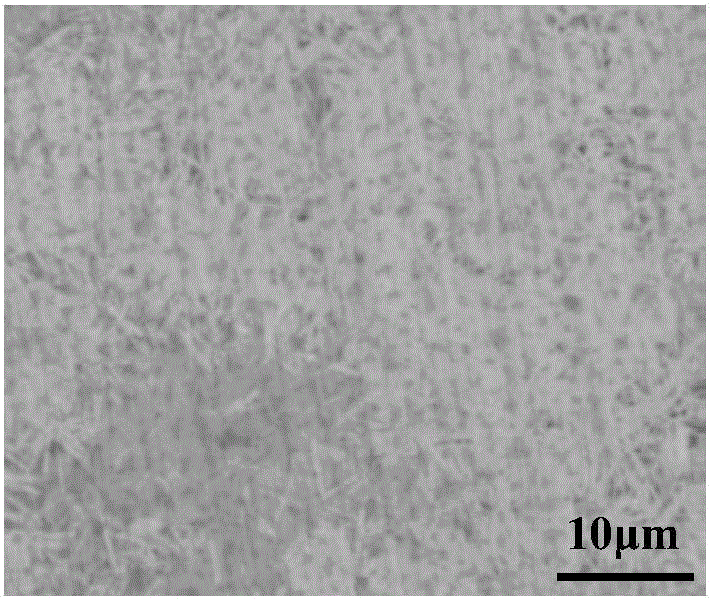

[0029] According to XRD, SEM and app...

Embodiment 2

[0031] A method for surface modification of a W / Al composite material, specifically comprising the steps of:

[0032] (1) First, place the W / 2024Al composite material with a W volume percentage of 20% in a high-frequency induction heating furnace, and adjust the position of the material in the high-frequency induction heating coil;

[0033] (2) Turn on the power of the equipment, vacuumize the induction heating furnace (less than 0.1Pa) or pass in an inert gas (argon or nitrogen, etc.) to protect the atmosphere;

[0034] (3) Set the frequency of induction heating to 100KHZ, start induction heating, each induction heating time is 5s, and continue the next induction heating after the pause time is greater than 10min, and conduct induction heating for a total of 5 times until the surface heating temperature reaches 700°C , to generate a dense protective layer of tungsten-aluminum intermetallic compound on the surface area of the material.

[0035] According to XRD, SEM and app...

Embodiment 3

[0037] A method for surface modification of a W / Al composite material, specifically comprising the steps of:

[0038] (1) first place the W / Al composite material with a volume percentage of W of 10% in a high-frequency induction heating furnace, and adjust the position of the material in the high-frequency induction heating coil;

[0039] (2) Turn on the power of the equipment, vacuumize the induction heating furnace (less than 0.1Pa) or pass in an inert gas (argon or nitrogen, etc.) to protect the atmosphere;

[0040] (3) Set the frequency of induction heating to 50KHZ, start induction heating, each induction heating time is 5s, and continue the next induction heating after the pause time is greater than 10min, a total of 5 times of induction heating, until the surface heating temperature reaches 600°C , to generate a dense protective layer of tungsten-aluminum intermetallic compound on the surface area of the material.

[0041] According to XRD, SEM and appearance inspect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com