Buffer composite packaging paper and preparation method thereof

A composite packaging and high molecular polymer technology, applied in the field of cushioning composite packaging paper and its preparation, can solve the problems of lack of moisture-proof and waterproof, poor cushioning and shock-absorbing effect of packaging paper, etc., achieve better waterproof effect, ensure cushioning reduction Shock effect, a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

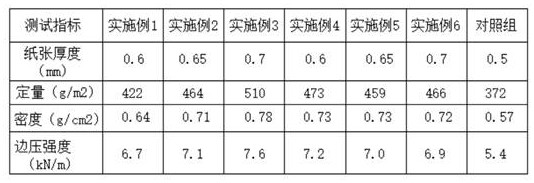

Examples

Embodiment 1

[0023] According to 25 parts of tapioca starch, 15 parts of styrene propylene, 13 parts of crotonate, 5 parts of paraffin, 2 parts of sodium dodecylbenzenesulfonate, and the parts by weight of 1 part of silicon dioxide are prepared by weighing and preparing the moisture-proof agent for subsequent use;

[0024] The calcium carbonate and the titanate coupling agent were fully mixed and reacted for 6 hours according to the weight ratio of 3:1 to prepare a modified foaming agent for use;

[0025] Weigh the wrapping paper raw material according to the following parts by weight: 6 parts by weight of brucite fiber, 3 parts by weight of modified foaming agent, 60 parts by weight of talcum powder, 10 parts by weight of high molecular polymer, 5 parts by weight of Dispersant, the moistureproof agent of 10 parts by weight;

[0026] Soak the brucite fiber in the modified foaming liquid for 24 hours, and the soaking temperature is 50°C, then filter and dry to obtain the fibrous foaming age...

Embodiment 2

[0028] According to 27 parts of tapioca starch, 17 parts of styrene propylene, 15 parts of crotonate, 7 parts of paraffin, 4 parts of sodium dodecylbenzene sulfonate, and the parts by weight of 3 parts of silicon dioxide are prepared by weighing and preparing the moisture-proof agent for subsequent use;

[0029] Calcium carbonate and titanate coupling agent were fully mixed and reacted for 6 hours according to the weight ratio of 3:1.5 to prepare a modified foaming agent for use;

[0030] Weigh the wrapping paper raw material according to the following parts by weight: 12 parts by weight of brucite fiber, 6 parts by weight of modified foaming agent, 75 parts by weight of talcum powder, 12 parts by weight of high molecular polymer, 7 parts by weight of Dispersant, the moistureproof agent of 15 parts by weight;

[0031] Soak the brucite fiber in the modified foaming liquid for 24 hours, and the soaking temperature is 55°C, then filter and dry to obtain the fibrous foaming agent;...

Embodiment 3

[0033] According to 30 parts of tapioca starch, 17 parts of styrene propylene, 15 parts of crotonate, 6 parts of paraffin, 3 parts of sodium dodecylbenzenesulfonate, and 3 parts of silicon dioxide, the moistureproof agent is prepared by weighing and preparing for subsequent use;

[0034] The calcium carbonate and the titanate coupling agent were fully mixed and reacted for 6 hours according to the weight ratio of 3:2 to prepare a modified foaming agent for use;

[0035] Weigh the wrapping paper raw material according to the following parts by weight: 18 parts by weight of brucite fiber, 9 parts by weight of modified foaming agent, 90 parts by weight of talcum powder, 15 parts by weight of high molecular polymer, 10 parts by weight of Dispersant, the moistureproof agent of 20 parts by weight;

[0036] Soak the brucite fiber in the modified foaming solution for 24 hours, and the soaking temperature is 60°C, then filter and dry to obtain a fibrous foaming agent; mix the fibrous f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com