High-strength low alloy steel force transfer rod and manufacturing method thereof

A technology of low-alloy steel and manufacturing method, applied to roads, pavement details, roads, etc., can solve problems such as low strength of dowel bars, non-corrosion resistance, short fatigue life, etc., and achieve the effect of economic value and maintenance cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

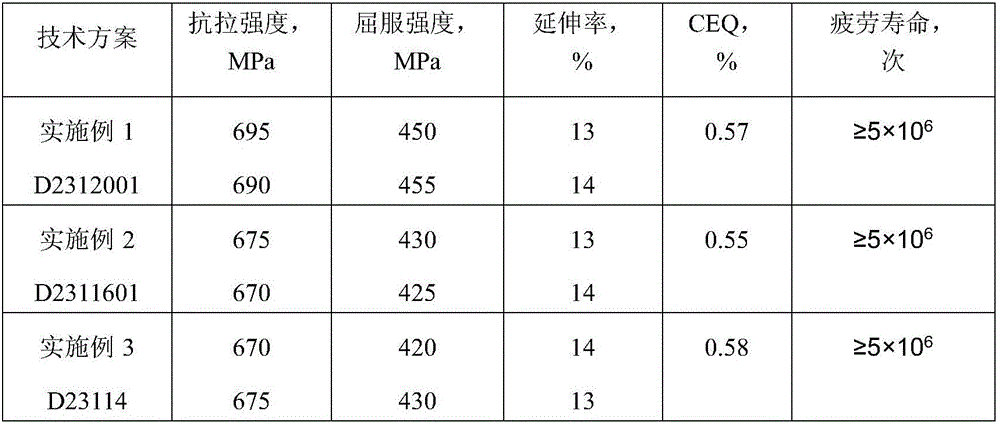

Examples

Embodiment Construction

[0026] The technological steps of embodiment 1~3 are: the first step: smelting

[0027] Electric furnace smelting, the tapping temperature is not lower than 1580°C, the tapping amount is 51.6t, and the alloying elements Mn and Cr are adjusted to the lower limit of the target value before tapping.

[0028] When the LF refining ladle is in place, it is energized to heat up, and the composition is fine-tuned to the required composition range of the finished product.

[0029] The continuous casting start temperature is the liquidus temperature plus 60-80°C. Continuous casting casts a 150mm×150mm square continuous casting billet with a billet length of 9000mm.

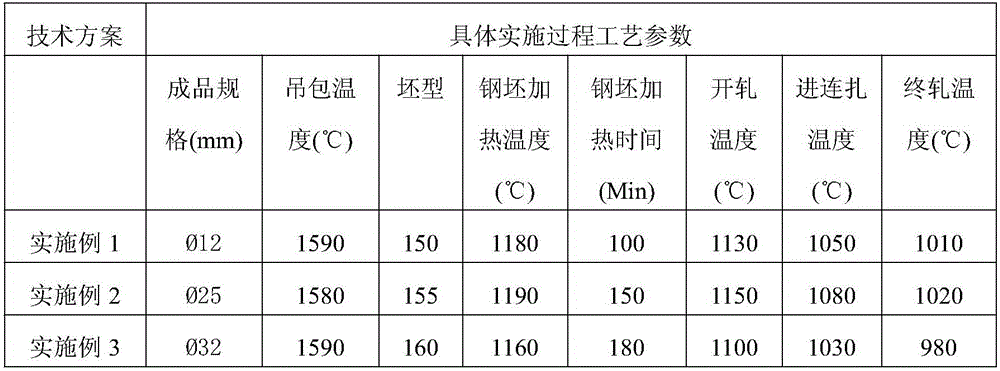

[0030] Step Two: Rolling

[0031] Heating process: The heating process adopts furnace insulation below 800°C, and the temperature is raised to 1160°C-1240°C at a speed of no more than 100°C / h, and then kept for more than 1.5 hours.

[0032] Rolling process: the starting rolling temperature is not lower than 1060°C; the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com