Processing method for producing lubricant base oil and liquid fuel by using inferior heavy oil

A lubricating oil base oil and processing method technology, which is applied in the field of lubricating oil base oil, can solve the problems of poor quality heavy oil, low separation precision, and affecting product quality, so as to reduce device start-up and shutdown, improve yield and product quality, Effect of reducing gas and coke yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

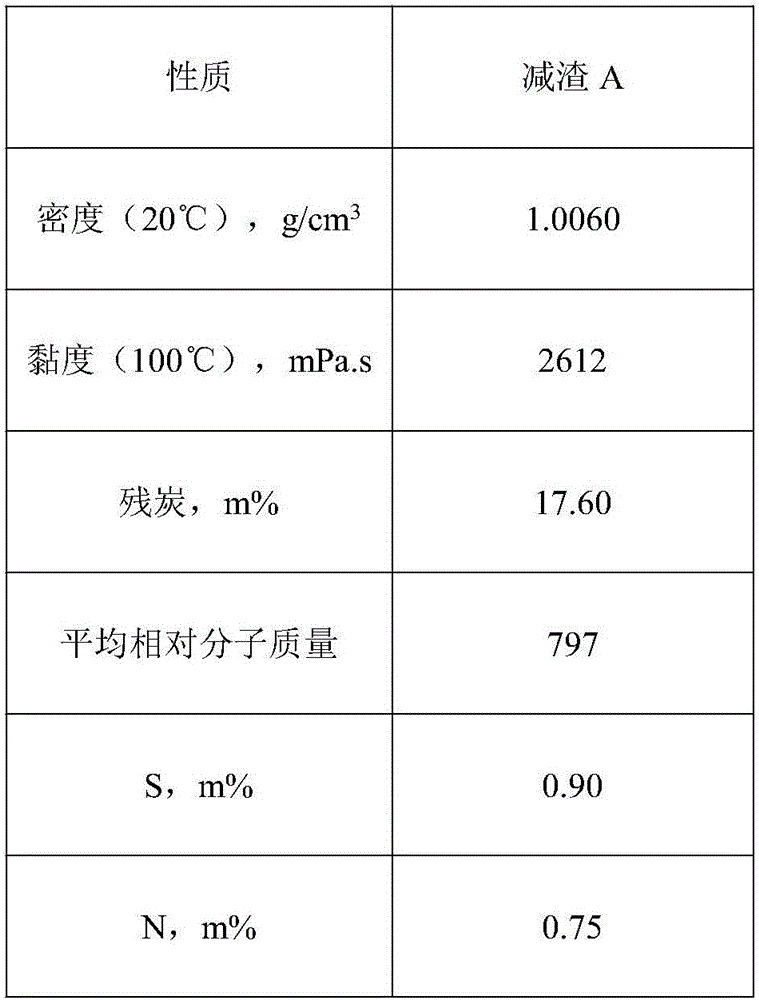

[0046] Example 2 of the present invention: VGO / VR=3:1 (m / m) mild hydroprocessing-catalytic cracking

[0047] Vacuum residual oil (referred to as VR) and vacuum gas oil (referred to as VGO) of a certain inferior crude oil are selected as the mixed feed for hydrotreating, and the mixing ratio of the two is VGO / VR=3:1 (m / m) ; Hydrotreating reaction conditions are temperature 390°C, pressure 9MPa, liquid hourly space velocity 1.0h -1 . The catalytic cracking experiment of hydrotreated oil was carried out on a small fixed fluidized bed reactor, using LBO-16 catalyst, the catalytic cracking reaction temperature was 500°C, the catalyst-to-oil ratio was 5, and the space velocity was 30h -1 . The yields of catalytic cracking dry gas, liquefied petroleum gas, gasoline, diesel and heavy oil were measured, and the amount of coke on the catalyst was analyzed. The distribution of catalytic cracking products is shown in Table 3.

[0048] Table 3 Product distribution wt% of catalytic crack...

Embodiment 3

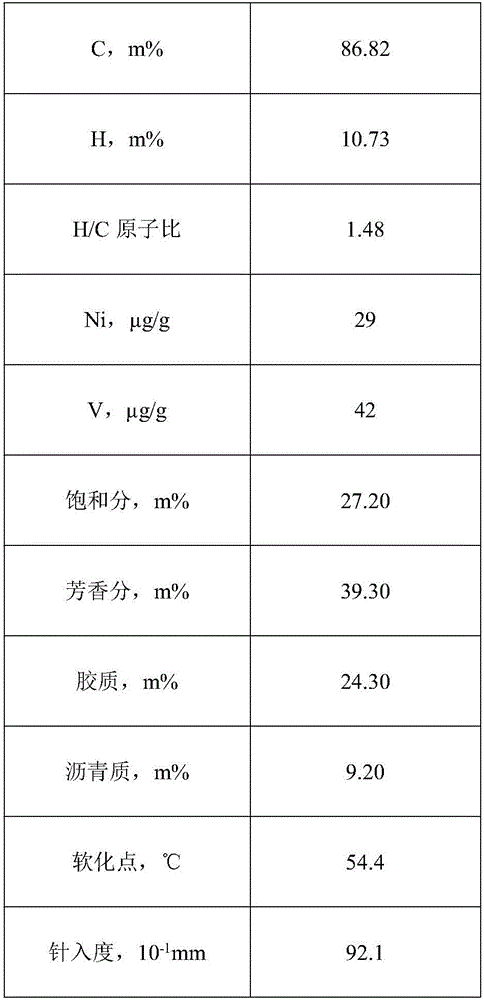

[0050] Embodiment 3 of the present invention: Selective solvent deasphalting of residual oil-hydroprocessing-catalytic cracking

[0051] The vacuum residue VR of an inferior crude oil was selected as raw material, and solvent deasphalting was carried out with pentane as solvent to obtain light deasphalted oil LDAO and heavy deasphalted oil HDAO. The properties of deasphalted oil LDAO and HDAO are shown in Table 4.

[0052] Table 4 Properties of LDAO and HDAO

[0053]

[0054] LDAO and VGO are mixed according to a certain mass ratio of 1:1 as the feed for hydroprocessing (I), and the reaction conditions of hydroprocessing are temperature 370°C, pressure 10.5MPa, liquid hourly space velocity 1.0h -1 .

[0055] The product distribution after hydroprocessing (I) is shown in Table 4. The raw material A is VGO, and the raw material B is a mixture of LDAO and VGO at a mass ratio of 1:1.

[0056] The properties of some products after two kinds of raw materials and hydroprocessin...

Embodiment 4

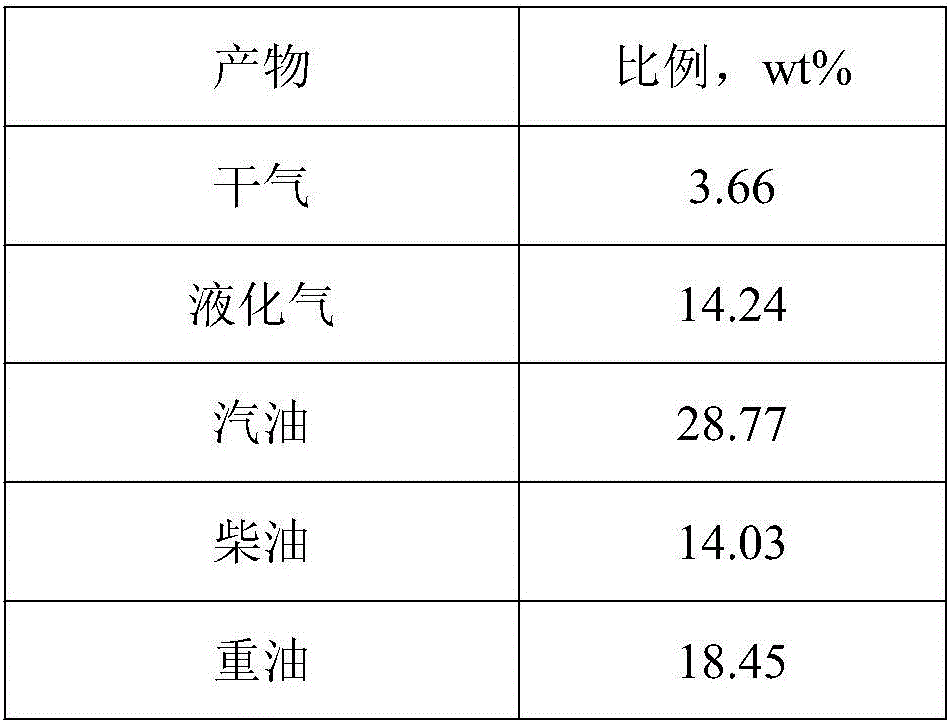

[0066] Example 4 of the present invention: Selective solvent deasphalting-hydroprocessing-catalytic cracking-oil slurry reverse mixing hydroprocessing (II) raw material

[0067] A poor-quality vacuum residue VR was selected as raw material, and pentane was used as solvent for selective solvent deasphalting to obtain deasphalted oils LDAO and HDAO. LDAO and VGO are mixed according to the mass ratio of 1:1 and used as the feed for hydroprocessing (I). The reaction conditions of hydroprocessing (I) are 380°C, pressure 12.5MPa, liquid hourly space velocity 1.2h -1 .

[0068] The product distribution after hydroprocessing (I) is shown in Table 7. The raw material A is VGO, and the raw material B is a mixture of LDAO and VGO at a mass ratio of 1:1.

[0069] The properties of some products after two kinds of raw materials and hydroprocessing (I) are shown in Table 8.

[0070] Table 7 Hydrofining reaction product distribution

[0071]

[0072]

[0073] Table 8 Raw materials a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com