A kind of ultra-low rolling resistance and ultra-high wet grip tire tread compound and its preparation method and tire

A rolling resistance, tire tread technology, applied in the direction of rolling resistance optimization, special tires, tire parts, etc., can solve the problem of not considering low rolling resistance performance, only considering wet grip performance, etc., to reduce the Payne effect of fillers, The effect of reducing heat generation and improving the grounding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

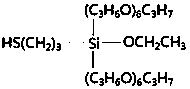

[0072] Raw material composition: 52 parts of solution polystyrene butadiene rubber Ⅰ, 26 parts of solution polystyrene butadiene rubber II, 22 parts of solution polystyrene butadiene rubber III, 90 parts of highly dispersed white carbon black 200MP, 12 parts of silane coupling agent I, 5 parts of silane Coupling agent Ⅱ, 10 parts of grip resin RICON330, 35 parts of high aromatic oil, 3.0 parts of anti-aging agent 6PPD, 2 parts of microcrystalline wax, 3 parts of zinc oxide, 1.5 parts of stearic acid, 2.5 parts of sulfur, 2.0 parts of accelerator CZ , 1.0 parts accelerator TOT-N.

[0073] Among them, solution polystyrene butadiene rubber Ⅰ: combined styrene accounts for 36% of the total weight of the polymer, vinyl accounts for 41% of the total weight of butadiene; solution polystyrene butadiene rubber II: combined styrene accounts for 42% of the total weight of the polymer %, vinyl accounts for 30% of the total weight of butadiene; solution polystyrene-butadiene rubber III: bo...

Embodiment 2

[0090] Raw material composition: 57 parts of solution polystyrene butadiene rubber Ⅰ, 23 parts of solution polystyrene butadiene rubber II, 20 parts of solution polystyrene butadiene rubber III, 100 parts of highly dispersed white carbon black 200MP, 14 parts of silane coupling agent I, 4 parts of silane Coupling agent II, 12 parts of grip resin RICON330, 40 parts of high aromatic oil, 4 parts of antioxidant 6PPD, 2 parts of microcrystalline wax, 3 parts of zinc oxide, 1.5 parts of stearic acid, 3.0 parts of sulfur, 2.3 parts of accelerator CZ , 0.5 parts accelerator TOT-N.

[0091] Among them, solution-polymerized styrene-butadiene rubber I, solution-polymerized styrene-butadiene rubber II and solution-polymerized styrene-butadiene rubber III are the same as in Example 1; the preparation method is the same as in Example 1.

Embodiment 3

[0093] Raw material composition: 61 parts of solution polystyrene butadiene rubber Ⅰ, 23.5 parts of solution polystyrene butadiene rubber II, 15.5 parts of solution polystyrene butadiene rubber III, 95 parts of highly dispersed white carbon black, 13 parts of silane coupling agent I, 3 parts of silane coupling Agent Ⅱ, 8 parts of grip resin RICON330, 37.5 parts of high aromatic oil, 2 parts of antiaging agent RD, 4 parts of antiaging agent 6PPD, 2 parts of microcrystalline wax, 3 parts of zinc oxide, 1.5 parts of stearic acid, 3.5 parts of sulfur, 1.9 Part accelerator CZ, 0.7 part accelerator TOT-N.

[0094] Among them, solution-polymerized styrene-butadiene rubber I, solution-polymerized styrene-butadiene rubber II and solution-polymerized styrene-butadiene rubber III are the same as in Example 1; the preparation method is the same as in Example 1.

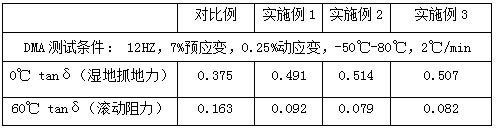

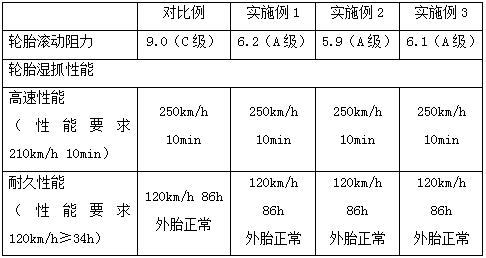

[0095] The relevant parameters of the ultra-low rolling resistance tire tread compound thus obtained are shown in Table 1, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com