Tundish coating and preparation method thereof

A smear and tundish technology, applied in the field of tundish smear and its preparation technology, can solve the problems of poor lubricating performance, easy to fall off, weak bonding performance, etc., achieve good lubricating performance, ensure purity, and enhance bonding performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

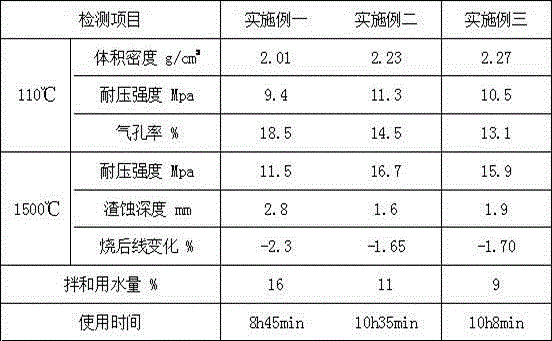

Examples

preparation example Construction

[0015] A preparation method for a tundish coating material, comprising the following steps:

[0016] (1) Crush the waste magnesia bricks to obtain waste magnesia brick particles; grind part of the waste magnesia brick particles into a powder with a diameter of less than or equal to 200 mesh; the other part is sieved through a 1mm and 3mm sieve to obtain a particle with a diameter between 0-1mm Waste magnesia brick particles between 1-3mm.

[0017] (2) Grind the magnesium powder into a powder with a diameter of 200 mesh or less.

[0018] (3) Detect the screened and ground waste magnesia brick particles and powder and magnesia powder.

[0019] (4) Proportioning the tested raw materials, silicon micropowder, water glass and hemp fiber according to the ratio of claim 1; mixing the raw materials for 5-10 minutes after the blending.

[0020] (5) The finished product after kneading is sub-packaged.

Embodiment 1

[0022] A tundish smear material, its main raw materials include waste magnesia bricks and 96 magnesia, and auxiliary materials include silicon micropowder, water glass and hemp fiber. The proportion of each component is as follows: the weight percentage of 200 mesh waste magnesia brick powder is 13%; the weight percentage of waste magnesia brick particles with a diameter of 0-1mm is 28%; %; The weight percentage of 200 order 96 magnesia is 7%; The weight percentage of silicon micropowder is 3%; The weight percentage of water glass is 0.2%; The weight percentage of hemp fiber is 0.9%.

[0023] A preparation method for a tundish coating material, comprising the following steps:

[0024] (1) Crush the waste magnesia bricks to obtain waste magnesia brick particles; grind part of the waste magnesia brick particles into a powder with a diameter of less than or equal to 200 mesh; the other part is sieved through a 1mm and 3mm sieve to obtain a particle with a diameter between 0-1mm ...

Embodiment 2

[0030] A tundish smear material, its main raw materials include waste magnesia bricks and 96 magnesia, and auxiliary materials include silicon micropowder, water glass and hemp fiber. The proportion of each component is as follows: the weight percentage of 200 mesh waste magnesium brick powder is 15%; the weight percentage of waste magnesium brick particles with a diameter of 0-1mm is 31%; the weight percentage of waste magnesium brick particles with a diameter of 1-3mm is 34% %; The weight percentage of 200 order 96 magnesia is 10%; The weight percentage of silicon micropowder is 5%; The weight percentage of water glass is 0.5%; The weight percentage of hemp fiber is 1.1%.

[0031] A preparation method for a tundish coating material, comprising the following steps:

[0032] (1) Crush the waste magnesia bricks to obtain waste magnesia brick particles; grind part of the waste magnesia brick particles into a powder with a diameter of less than or equal to 200 mesh; the other par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com