A diatom plate with photocatalytic function and its production process

A production process, diatom board technology, applied in the direction of manufacturing tools, floors, covering/lining, etc., to achieve the effect of excellent adsorption and humidity control, good humidity control function, heat insulation, light weight and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

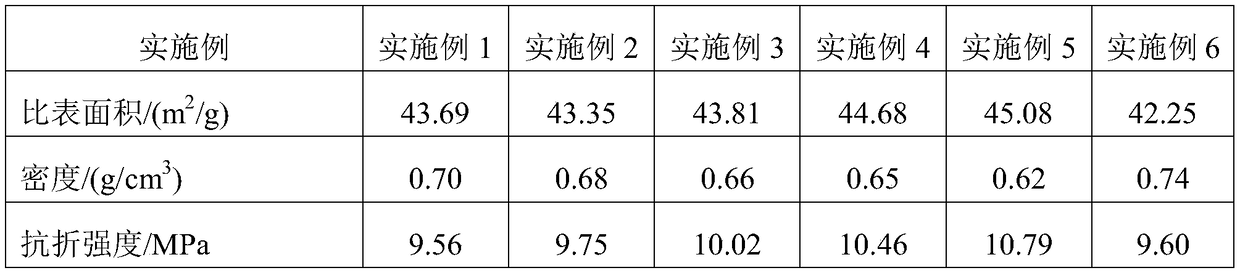

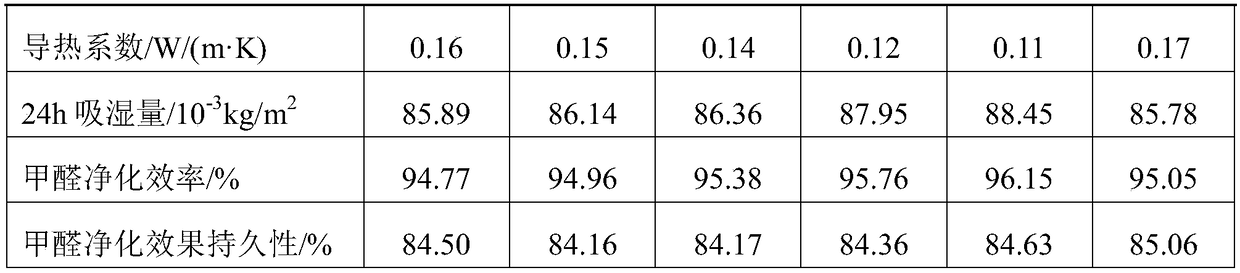

Examples

Embodiment 1

[0037] ①Weigh 35kg of diatomite, 40kg of lime, 10kg of volcanic ash, 10kg of wood fiber, 5kg of calcium sulfate whiskers, 1kg of hydroxyethyl cellulose, and 400kg of water according to formula A, and add them into a mixer for dispersion and slurry mixing to obtain slurry A; Formula B weighs 40kg of diatomite, 40kg of lime, 5kg of volcanic ash, 5kg of quartz powder, 5kg of wood fiber, 5kg of attapulgite, 1kg of methyl hydroxyethyl cellulose, nitrogen-doped nano-TiO 2 Add 1.2kg of diatomite composite material and 400kg of water into the mixer to disperse and adjust slurry to obtain slurry B;

[0038] ②Filter and convey the uniformly mixed slurry B through the flow machine, and spray the adhesive polyvinyl alcohol evenly on the surface of the filter cake before it reaches the rotary drum forming machine. The spraying amount is the solid mass of the sprayed filter cake. 1.0%; the rotary drum forming machine rolls the filter cake of the slurry B uniformly sprayed with the adhesive ...

Embodiment 2

[0043] ①Weigh 30kg of diatomite, 40kg of lime, 10kg of volcanic ash, 5kg of quartz powder, 8kg of wood fiber, 7kg of calcium sulfate whiskers, 1.2kg of hydroxyethyl cellulose according to formula A, and add 360kg of water into the mixer to disperse and adjust the slurry to obtain Slurry A; Slurry B formula is the same as embodiment 1;

[0044] ②Filter and convey the uniformly mixed slurry B through the flow machine, and spray the adhesive polyethylene glycol evenly on the surface of the filter cake before it reaches the rotary drum forming machine, and the spraying amount is the solid mass of the sprayed filter cake 1.3% of 1.3%; the rotary drum forming machine rolls the slurry B filter cake with the surface evenly sprayed with adhesive on the rotating drum; Slurry A filter cake solid mass 0.7% binder polyethylene glycol, after slurry A is rolled continuously for 12 layers, it is automatically replaced with slurry B, and the whole laminated wet diatom is completed after slurry...

Embodiment 3

[0049] ①Weigh 40kg of diatomite, 35kg of lime, 10kg of quartz powder, 11kg of wood fiber, 4kg of calcium sulfate whiskers, 1.5kg of ethyl hydroxyethyl cellulose, and 400kg of water into a mixer for dispersion and slurry preparation according to formula A. Slurry A; Slurry B formula is the same as embodiment 1;

[0050] ②Filter and convey the uniformly mixed slurry B through the flow machine, and spray the adhesive polyvinyl alcohol evenly on the surface of the filter cake before it reaches the rotary drum forming machine. The spraying amount is the solid mass of the sprayed filter cake. 1.2%; the rotary drum forming machine rolls the slurry B filter cake with the surface evenly sprayed with adhesive on the rotating drum; after rolling one layer, the flow machine automatically changes to filter and convey the slurry A, and sprays the material Slurry A filter cake solid mass 0.6% binder polyvinyl alcohol, after slurry A is continuously rolled for 14 layers, it is automatically r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com