Low-melting-point and low-cadmium sliver brazing filler metal

A low-melting-point silver solder technology, applied in welding/cutting media/materials, welding media, metal processing equipment, etc., can solve the problems of limited annual output, difficult processing of silver solder, and lack of mass application, etc., to achieve The effect of reducing the content, avoiding oxidation or even softening of the workpiece, and good wetting and spreading properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

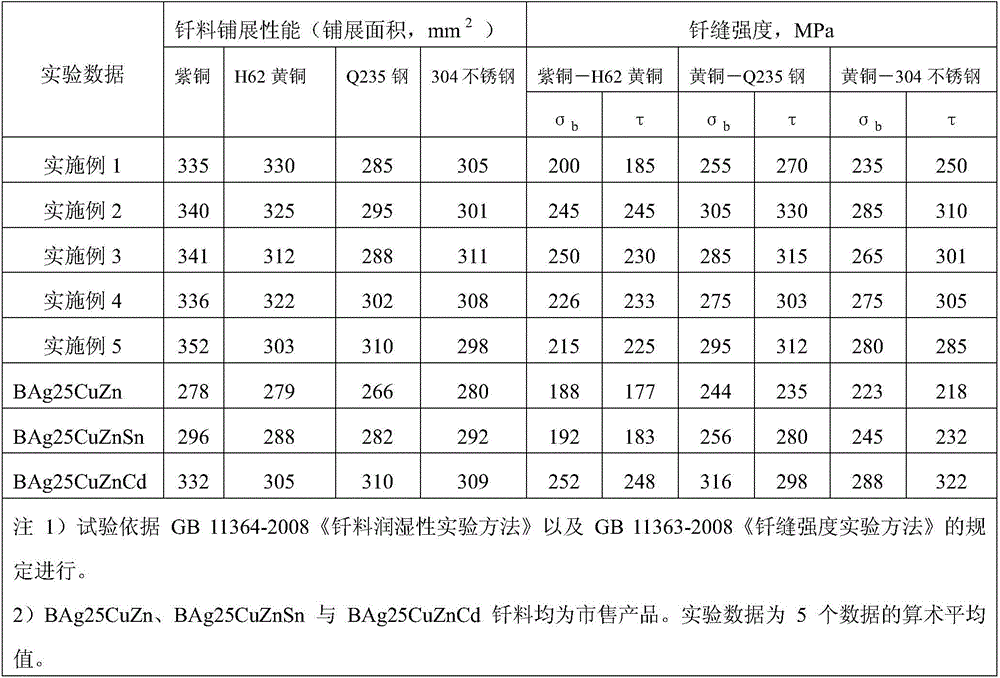

Embodiment 1

[0019] The chemical composition is: 24.0% Ag, 41.0% Cu, 0.05% Cd, 0.001% In, 0.005% Ga, and the balance is Zn.

[0020] The solidus temperature of the low-melting-point low-cadmium silver solder obtained in this example is in the range of 630° C. to 645° C., and the liquidus temperature is in the range of 695° C. to 710° C. (measurement errors are considered). See the data in brackets for the strength of the brazing seam when the flame brazing method is used, with FB102 flux, and the brazing base material is the following combination: red copper-H62 brass (σ b =225±25MPa, τ=215±30MPa), brass-Q235 steel (σ b =280±25MPa, τ=300±30MPa), brass-304 stainless steel (σ b =260±25MPa, τ=280±30MPa).

Embodiment 2

[0022] The chemical composition is: 26.0% Ag, 30.0% Cu, 0.13% Cd, 0.001% In, 0.001% Ga, and the balance is Zn.

[0023] The solidus temperature of the low-melting-point low-cadmium silver solder obtained in this example is in the range of 630° C. to 645° C., and the liquidus temperature is in the range of 695° C. to 710° C. (measurement errors are considered). See the data in brackets for the strength of the brazing seam when the flame brazing method is used, with FB102 flux, and the brazing base material is the following combination: red copper-H62 brass (σ b =225±25MPa, τ=215±30MPa), brass-Q235 steel (σ b =280±25MPa, τ=300±30MPa), brass-304 stainless steel (σ b=260±25MPa, τ=280±30MPa).

Embodiment 3

[0025] The chemical composition is: 25.0% Ag, 36.0% Cu, 0.10% Cd, 0.005% In, 0.005% Ga, and the balance is Zn.

[0026] The solidus temperature of the low-melting-point low-cadmium silver solder obtained in this example is in the range of 630° C. to 645° C., and the liquidus temperature is in the range of 695° C. to 710° C. (measurement errors are considered). See the data in brackets for the strength of the brazing seam when the flame brazing method is used, with FB102 flux, and the brazing base material is the following combination: red copper-H62 brass (σ b =225±25MPa, τ=215±30MPa), brass-Q235 steel (σ b =280±25MPa, τ=300±30MPa), brass-304 stainless steel (σ b =260±25MPa, τ=280±30MPa).

PUM

| Property | Measurement | Unit |

|---|---|---|

| solidus temperature | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

| solidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com