Method for assembling tundish prestressing force applying mechanism and preparation technology of downwarping-preventing tundish

An assembly method and a tundish technology, which are applied in the field of iron and steel metallurgical continuous casting, can solve problems such as deflection and deformation, and achieve the effects of improving service life, avoiding excessive temperature, and increasing continuous casting furnaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

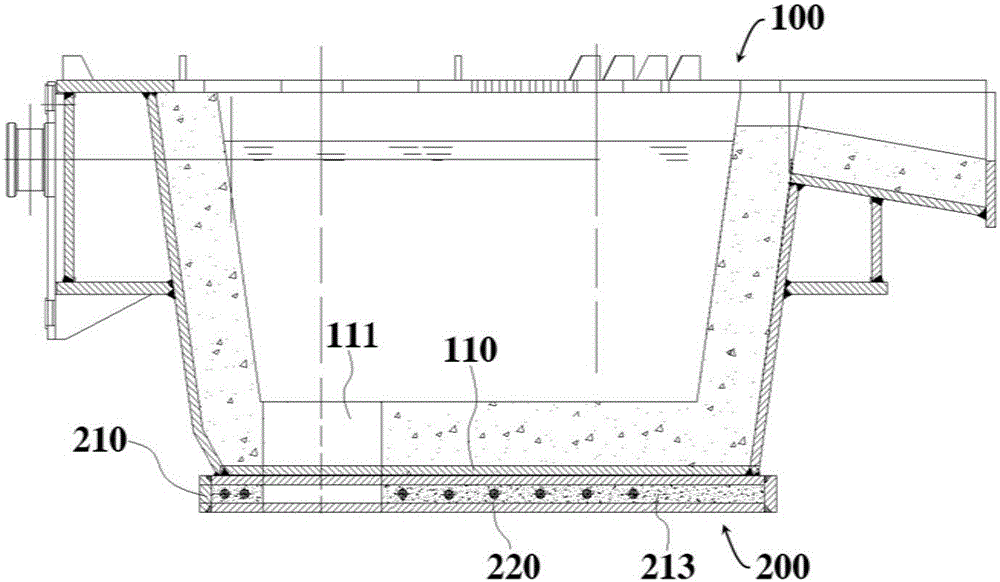

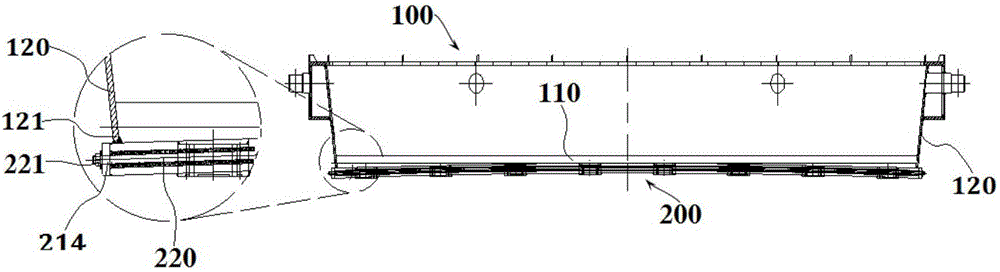

[0053] Such as Figure 5 As shown, an assembly method of a tundish prestressing mechanism in this embodiment:

[0054] (1) Preparation of concrete

[0055] The quality of each component is as follows: 45kg of cement, 35kg of refractory aggregate, 10kg of filler, 13kg of additive, 1kg of antirust agent, 1kg of water reducing agent, and 5kg of water to obtain the mixture, and add the mixture to the mixer and stir for 10-20min. Obtain refractory concrete slurry after stirring evenly;

[0056] Wherein the above cement is C60 Portland cement, the filler is composed of copper powder and crushed stone, and the ratio of copper powder and crushed stone is 1:1, the copper powder is deoxidized copper powder, and the particle size of the filler is 3 ~10mm continuously graded granular material, the additives are composed of water glass and sodium fluorosilicate, the masses are respectively 8 kg of water glass and 5 kg of sodium fluorosilicate. The refractory aggregate is composed of zir...

Embodiment 2

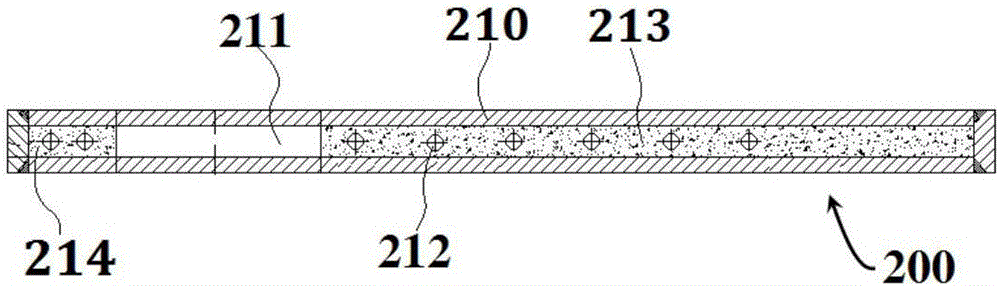

[0096] The basic content of this embodiment is the same as that of Embodiment 1, except that the 10-strand billet continuous casting machine of 3#10 machine of a certain company’s No. 1 and Table 2, it can be seen that the distance between the centers of steel bar sleeves 212 is 100 mm, and the diameter of steel bar sleeves 212 is The diameter of the prestressed steel bar 220 is The deformation of the designed prestress applying mechanism 200 is D=70mm, and the designed prestress of the prestress applying mechanism 200 is 500MPa.

[0097] A method of applying prestress to control the deflection of the tundish in this embodiment: each component of the heat-resistant concrete is composed of the following parts by mass: 43 kg of cement, 25 kg of refractory aggregate, 5 kg of filler, 8 kg of additive, 1 kg of antirust agent, and Aqua 1kg, water 5kg; Wherein the above-mentioned cement is C60 portland cement, and described filler is to be made up of copper powder, converter wind-...

Embodiment 3

[0104] The basic content of this embodiment is the same as that of Embodiment 1, except that the components of the heat-resistant concrete are composed according to the following mass parts: 40 kg of cement, 30 kg of refractory aggregate, 8 kg of filler, 15 kg of additive, 1 kg of antirust agent, water reducing agent Agent 1kg, water 5kg; Wherein the above-mentioned cement is C60 portland cement, and described filler is made up of copper powder, blast furnace slag, crushed stone, and ratio is 1:1:1, and described copper powder is deoxidized copper powder, the particle size of the filler is continuously graded from 3 to 10 mm, and the additives are composed of water glass and sodium fluorosilicate, and the masses are 9 kg of water glass and 6 kg of sodium fluorosilicate.

[0105] When the tundish of this embodiment is used for continuous casting, the number of continuous casting furnaces reaches 58 furnaces. The tundish of this embodiment does not have bad plastic deformation, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com