A kind of oxygen carrier for producing high-quality syngas and its preparation method and application

An oxygen carrier and synthesis gas technology, which is applied in the chemical method of reacting gas medium with gas medium, gas and gas reaction under catalytic active body, gas fuel, etc., can solve the problem of low cycle reaction activity, investment and operating costs It can improve the conversion rate of CH4, increase the conversion rate of methane, and improve the selectivity of synthesis gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the present invention comprises the following steps:

[0042] 1) Dissolve barium nitrate / lanthanum nitrate in 60-80°C deionized water to obtain barium nitrate / lanthanum nitrate solution; dissolve ferric nitrate in 60-80°C deionized water to obtain ferric nitrate solution; dissolve aluminum nitrate in 60 Aluminum nitrate solution is obtained in deionized water at ~80°C; barium nitrate / lanthanum nitrate solution, ferric nitrate solution, and aluminum nitrate solution are all 0.9-1.2mol / L, and the concentration of cerium nitrate solution is 0.1-40.5mol / L;

[0043] 2) After uniformly mixing the barium nitrate / lanthanum nitrate solution and the ferric nitrate solution, use 0.1-2mol / L nitric acid to adjust the pH value to 1-2, then add the aluminum nitrate solution, and mix well to obtain a mixed solution; wherein the barium nitrate / The mol ratio of lanthanum nitrate and ferric nitrate is 1:n, and the mol ratio of ferric nitrate and aluminum nitrate...

Embodiment 1

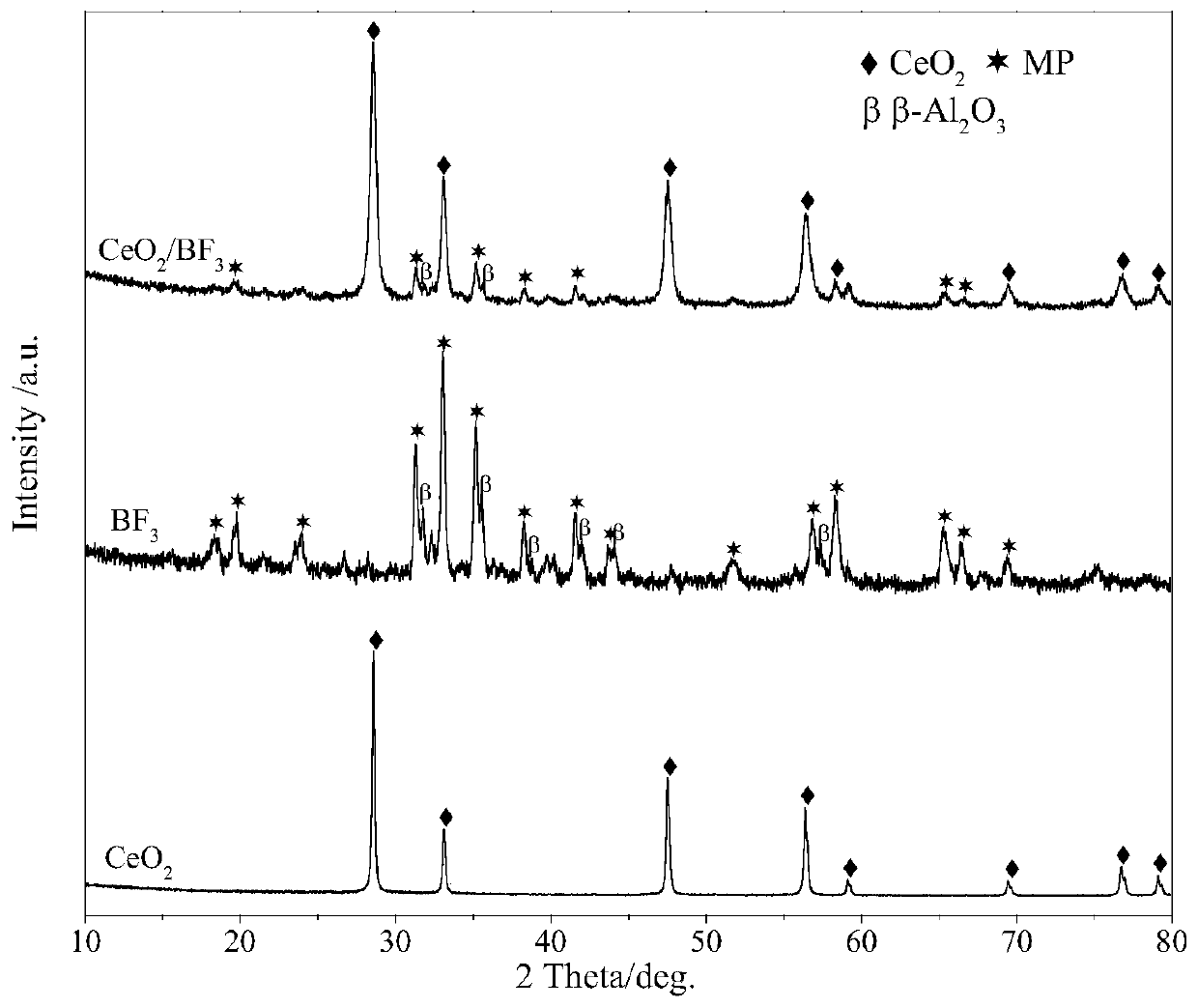

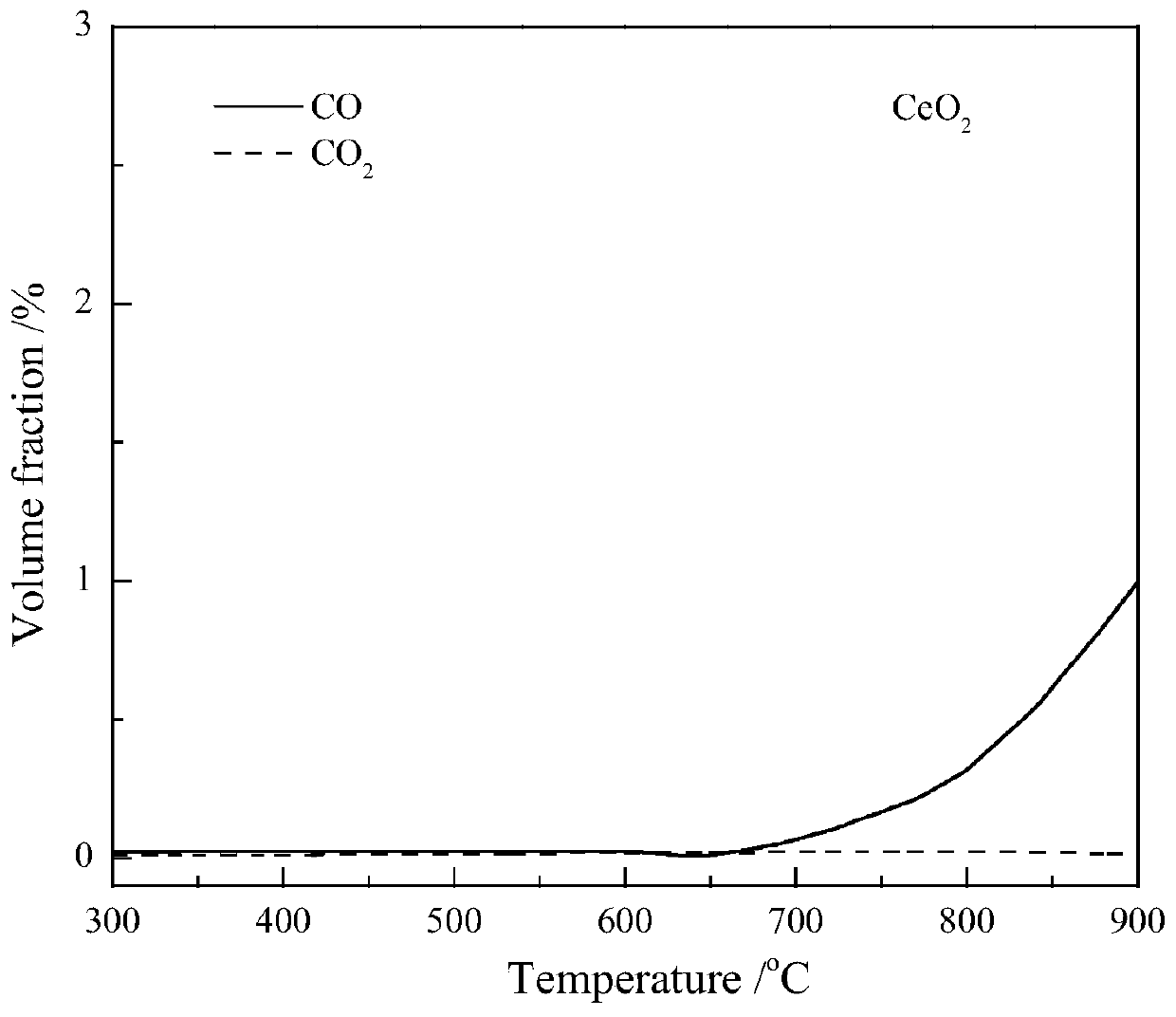

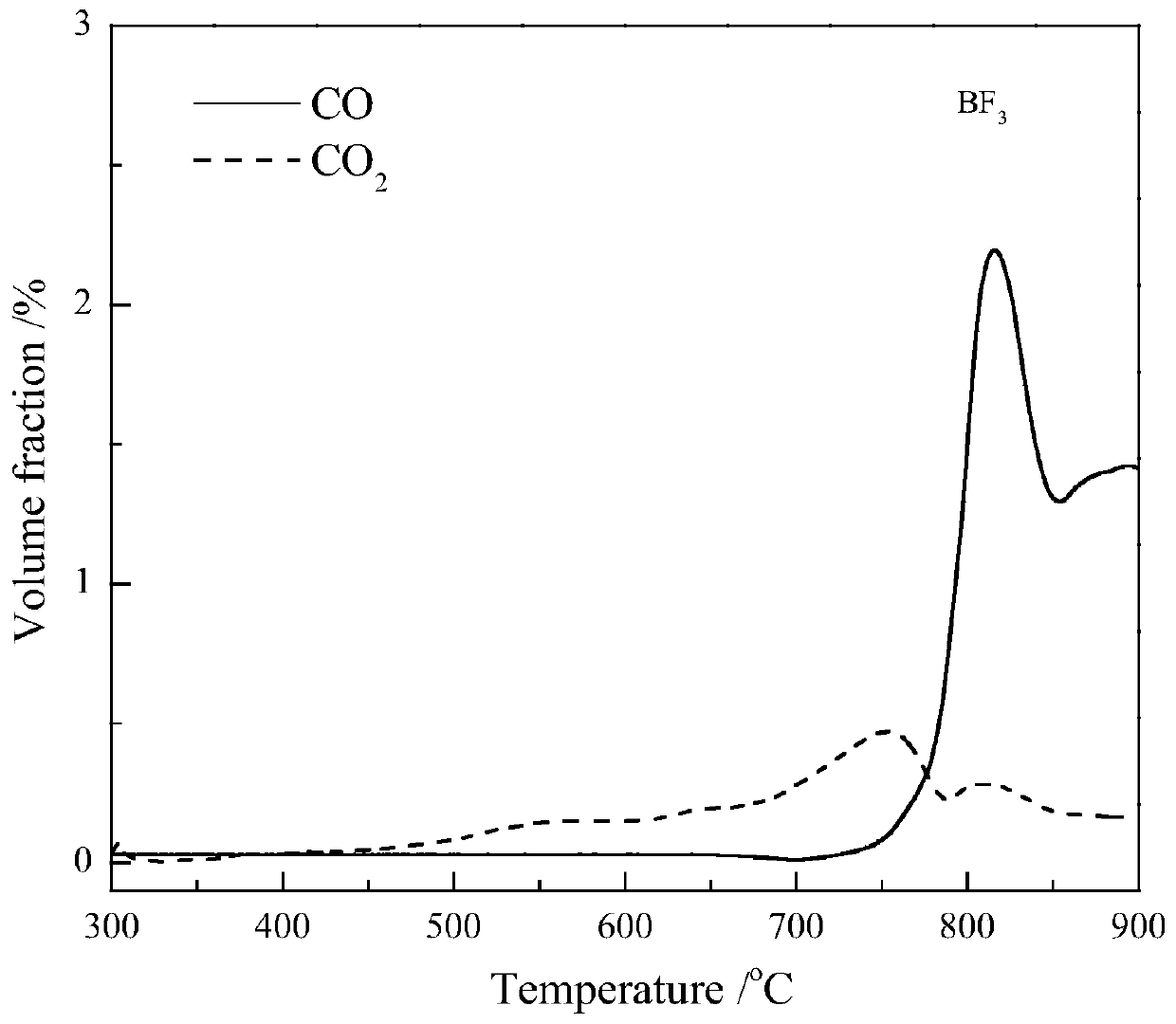

[0057] Non-equilibrium plasma treatment of CeO prepared by impregnation method 2 -BF 3 (x=0.5) Complex oxygen carriers. Barium nitrate (Ba(NO 3 ) 2 ), ferric nitrate (Fe(NO 3 ) 3 9H 2 O) and aluminum nitrate (Al(NO 3 ) 3 9H 2 O) were respectively dissolved in deionized water at 70° C. to form 1.0 mol / L solutions of barium nitrate, iron nitrate and aluminum nitrate. After mixing barium nitrate solution and ferric nitrate solution evenly, use 0.1moL / L nitric acid to adjust the pH value to 1.0, then add aluminum nitrate solution, after mixing evenly, to obtain a mixed solution, quickly add the mixed solution to an excess of 1.1mol / L In L saturated ammonium carbonate solution, stir rapidly at 70°C at a speed of 625r / min for 5 hours, filter and dry at 110°C for 11 hours, then first roast at 400°C for 4 hours, then roast at 1200°C for 5 hours, grind Oxygen carrier BF 3 .

[0058] Oxygen carrier BF 3 Slowly pour into the previously prepared 4.2mol / L cerium nitrate soluti...

Embodiment 2

[0060] Preparation of CeO prepared by non-equilibrium plasma treatment impregnation method at different calcination temperatures 2 -BF 3 (x=0.5) Complex oxygen carriers. Prepare the precursor CeO before roasting with the method of embodiment 1 earlier 2 -BF 3 , and then placed in a muffle furnace, first fired at 500°C for 4 hours, and then fired at 600°C, 700°C, 900°C, and 1000°C for 5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com