Drug-loaded protein microparticles and preparation method thereof

A technology of protein particles and proteins, applied in the field of materials science, can solve the problems of poor slow and controlled release of drugs, achieve significant technological progress, prolong the time of slow and controlled release, and prevent clogging problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Preparation of high-voltage electrostatic spraying working fluid

[0031] 12 g of zein and 2 g of ibuprofen were dissolved in 100 mL of a mixed solvent of acetic acid and ethanol, where the volume ratio of acetic acid:ethanol was 30:70.

[0032] The mixed solvent of acetic acid and ethanol with a volume ratio of 30:70 was used as the electrospray sheath fluid.

Embodiment 2

[0033] Example 2: Preparation of drug-loaded protein particles by ordinary single-jet high-voltage electrospray process

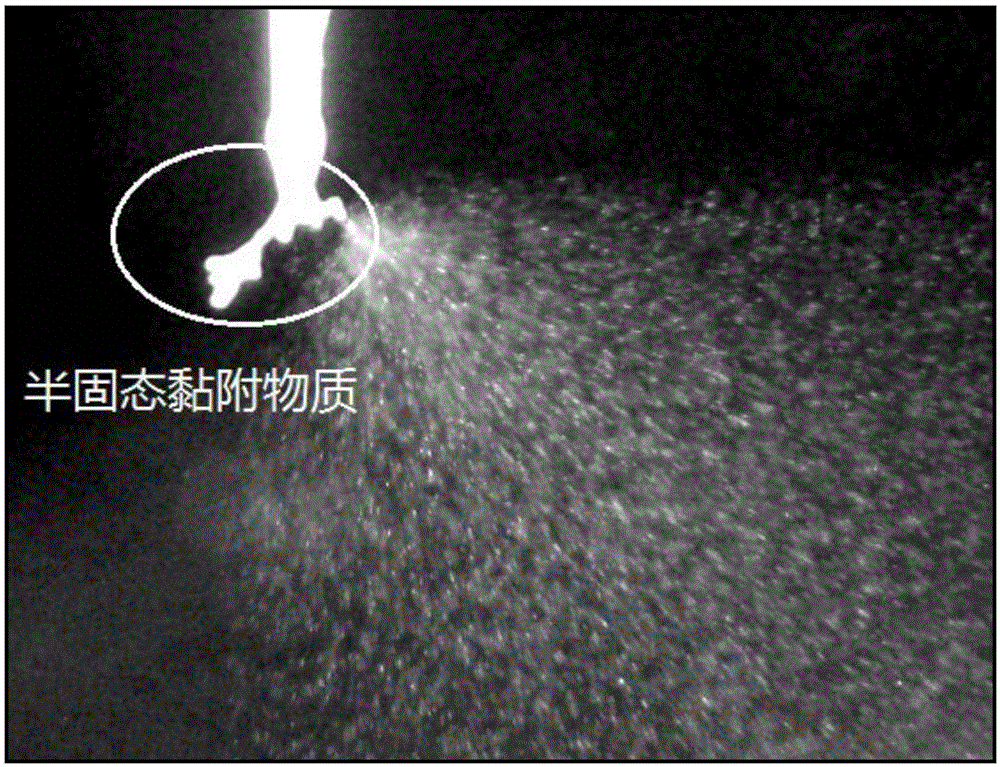

[0034] Put the eutectic solution of zein and 2 grams of ibuprofen into the syringe, install it on the syringe pump, use the metal capillary with an inner diameter of 0.6 mm as the nozzle, connect it directly to the front end of the syringe, connect the metal needle and DC high voltage Static generator. The flow rate of the working fluid was adjusted to 1.0 mL / h. When there are liquid droplets evenly dripping from the nozzle, start the high-voltage electrostatic generator. Under the working condition of applied voltage of 18 kV and receiving distance of 20 cm, a stable single-jet high-voltage electrostatic spraying process was started. Because proteins are easy to interact with metals, semi-solid adherent substances often hang on the nozzle during electrospray and block the nozzle (such as figure 1 shown). Therefore, these semi-solid substances composed...

Embodiment 3

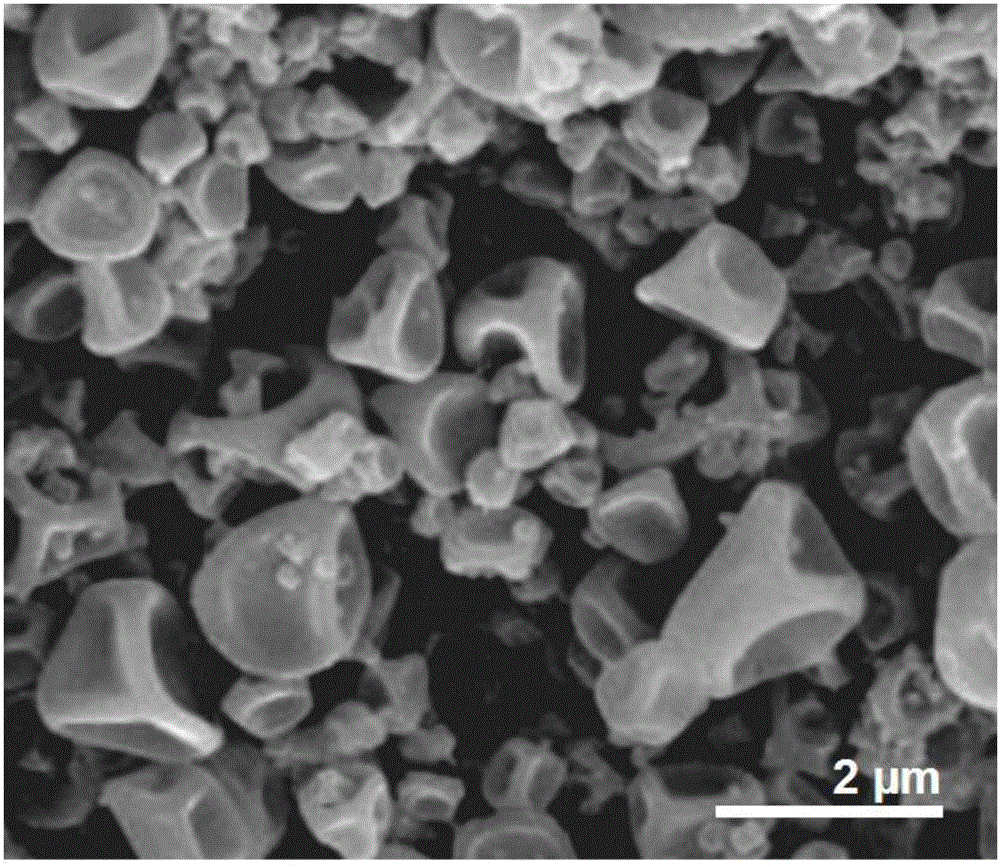

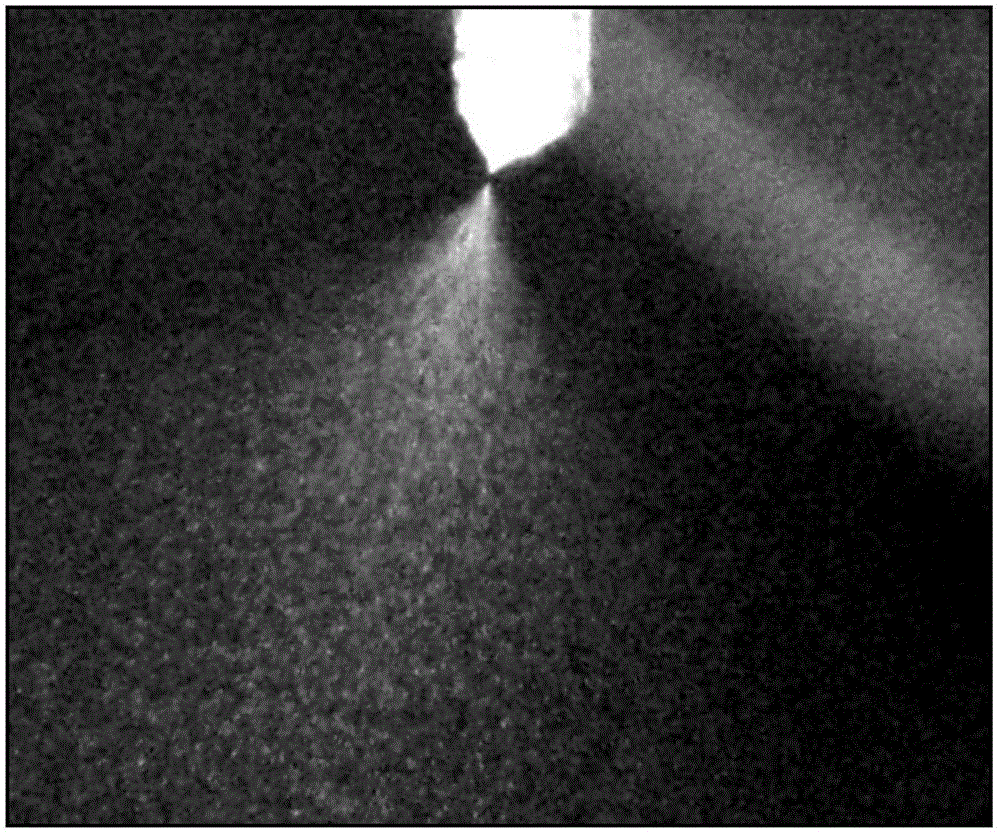

[0035] Example 3 Preparation of Drug-Loaded Protein Particles by Acidic Solvent Circulation Coaxial High-voltage Electrospray Process

[0036] A co-dissolved solution of zein and 2 g of ibuprofen was filled into a syringe and fitted to a syringe pump. The mixed solvent of acetic acid and ethanol with a volume ratio of 30:70 was filled into another syringe as electrospray sheath fluid, and installed on another syringe pump. The above two working fluids are injected into the coaxial spray head through the pump. Connect the coaxial nozzle and the DC high voltage electrostatic generator. The flow rate of the working fluid in the core was adjusted to 0.7 mL / h, and the flow rate of the working fluid in the sheath to 0.3 mL / h. When there are liquid droplets evenly dripping from the nozzle, start the high-voltage electrostatic generator. Under the working condition of applied voltage of 18 kV and receiving distance of 20 cm, a stable coaxial high-voltage electrostatic spraying proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com