Vitamin D3 soft capsule and preparation method thereof

A vitamin and soft capsule technology, applied in the field of vitamin D3 soft capsules and its preparation, can solve the problems of low bioavailability and poor stability, and achieve the effects of extending shelf life, easy absorption, and enhancing integrity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

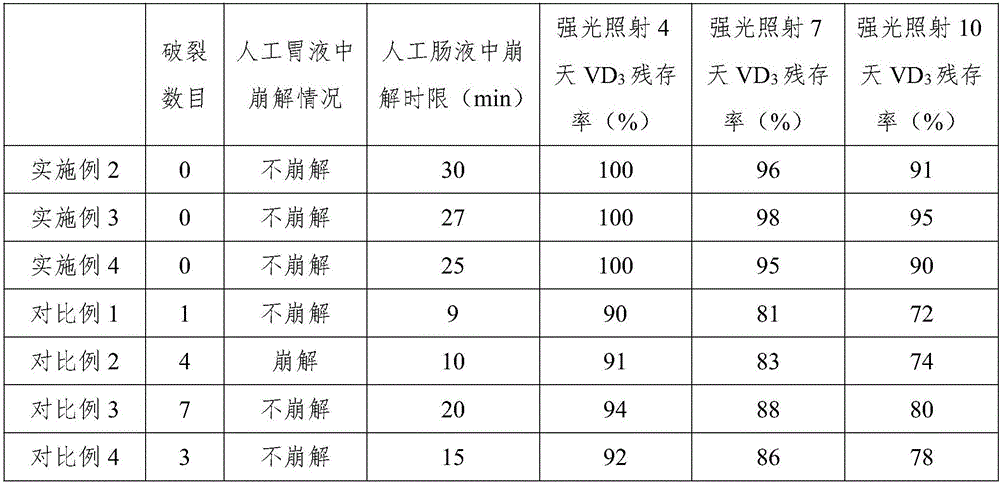

Examples

Embodiment 1

[0046] Embodiment 1, a kind of preparation of acylated gelatin

[0047] Prepare 70 parts of 3% bovine gelatin solution, add 2mol / L NaOH solution to adjust the pH value to 9.7, and put it in a water bath at a constant temperature of 65°C for 30 minutes; Amine tetraacetic dianhydride, adjust the pH value to 9.7, after the acylation reaction for 4 hours, dialyze the dialysis bag for 48 hours until the pH value of the water is 7, place it in a polyethylene glycol solution and concentrate to a protein concentration of 15%, then add 1 part 25% glutaraldehyde solution was cross-linked and solidified at 45° C. and 500 rpm / min constant temperature stirring for 60 minutes, aged at room temperature for 24 hours, frozen and dried to obtain the product.

Embodiment 2

[0048] Embodiment 2, a kind of vitamin D 3 soft capsule

[0049] The vitamin D 3 Soft capsules consist of contents and capsule shell:

[0050] The content consists of the following preparation raw materials and their parts by weight: Vitamin D 3 30 parts of powder and 40 parts of olive oil;

[0051] The vitamin D 3 The powder preparation method is:

[0052] A. 40 servings of vitamin D 3 , 50 parts of olive oil, 0.03 part of tert-butyl hydroquinone, 0.5 part of monoglyceride, heated to 45°C and stirred to obtain an oil phase;

[0053] B. Dissolve 5 parts of bovine gelatin, 20 parts of maltodextrin, 2 parts of sodium carboxymethylcellulose, and 3 parts of sucrose ester in 40 parts of purified water, heat to 45°C and stir to obtain the aqueous phase;

[0054] C. the oil phase obtained in step A is mixed with the water phase obtained in step B at a volume ratio of 1:1, homogenized 2 times under 20MPa conditions, each 20min, microemulsion, and the average particle diameter o...

Embodiment 3

[0066] Embodiment 3, a kind of vitamin D 3 soft capsule

[0067] The vitamin D 3 Soft capsules consist of contents and capsule shell:

[0068] The content consists of the following preparation raw materials and their parts by weight: Vitamin D 3 45 parts of powder and 55 parts of walnut oil;

[0069] The vitamin D 3 The powder preparation method is:

[0070] A. 48 Vitamin D 3 , 52 parts of walnut oil, 0.2 part of ethoxyquinoline, 0.8 part of glycerol monostearate, heated to 65 ° C and stirred to obtain an oil phase;

[0071] B. Dissolve 8 parts of soybean protein, 32 parts of β-cyclodextrin, 2 parts of sodium carboxymethyl cellulose, and 3 parts of sucrose ester in 60 parts of purified water, heat to 55°C, stir and mix to obtain the aqueous phase;

[0072] C. the oil phase obtained in step A is mixed with the water phase obtained in step B at a volume ratio of 1:1, homogenized 2 times under 40MPa conditions, each 30min, microemulsion, and the average particle diameter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com