Fishhook

A technology of fishing hooks and hydrolyzable groups, applied in the field of fishing hooks, can solve problems such as plating peeling, low impact resistance of fishing hooks, insufficient surface treatment of fishing hooks, etc., and achieve the effect of reducing stress and improving fishing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

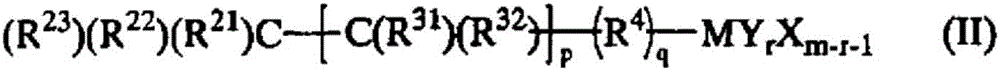

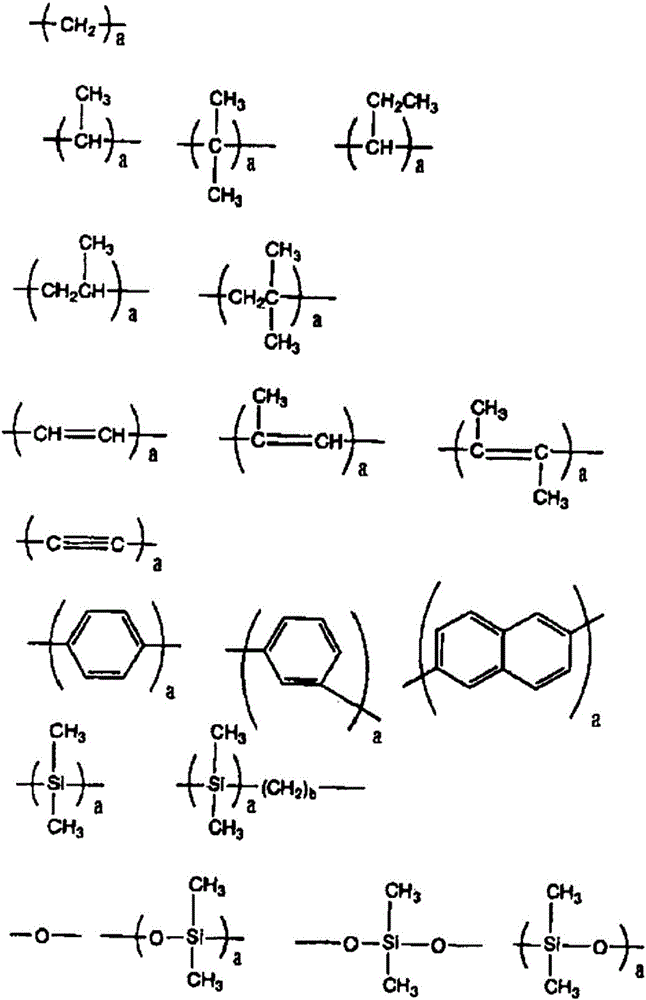

Method used

Image

Examples

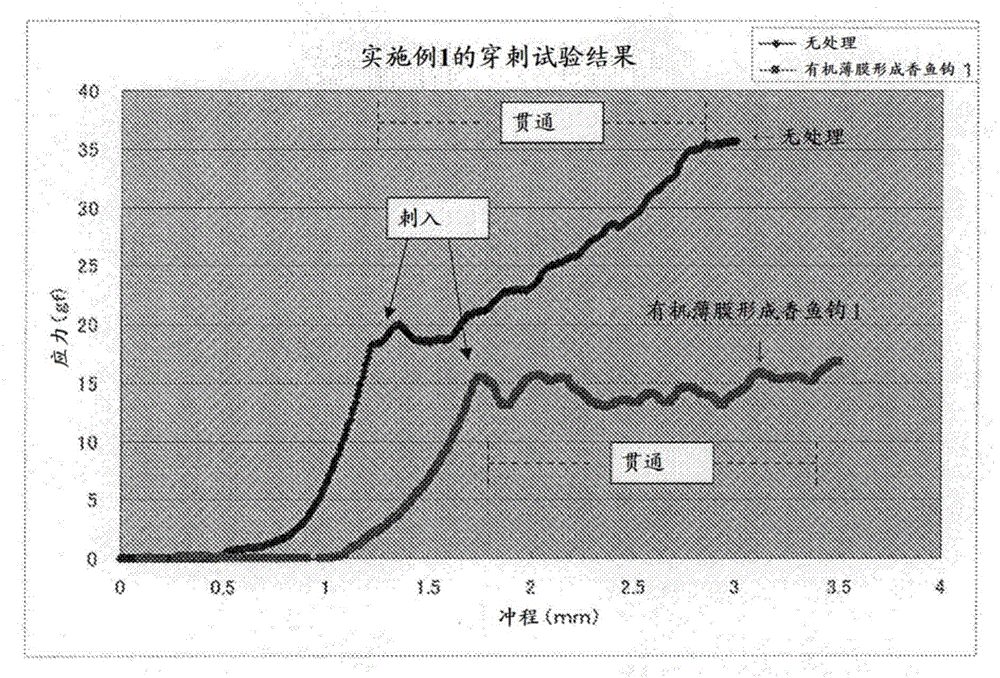

Embodiment 1

[0426] Put 100 sweetfish hooks (XP AIR SPEED, size: 6.5, manufactured by DAIWA Co., Ltd.) in a glass container, and perform four times with toluene, two times with acetone, one time with pure water, and one time with isopropanol. (Hereinbelow, it may be referred to as IPA) Ultrasonic cleaning was performed once, and the above-mentioned ultrasonic cleaning was performed for 10 minutes at a time.

[0427] Thereafter, the sweetfish hooks after ultrasonic cleaning were dried at 60° C. for 30 minutes, and dipped in a 1 M-sodium silicate aqueous solution at room temperature for 30 minutes.

[0428] After the treatment with the sodium silicate aqueous solution, the sodium silicate aqueous solution was sufficiently washed with pure water to remove the sodium silicate aqueous solution, further washed with IPA, and dried at 60° C. for 30 minutes.

[0429] Next, after immersing in a surface treatment composition (SAMLAY (registered trademark), manufactured by Nippon Soda Co., Ltd.) for 3...

Embodiment 2

[0431] Put 100 nickel-plated sweetfish hooks (XP AIR SPEED, size: 6.5, manufactured by DAIWA Co., Ltd.) in a glass container, and perform four times with toluene, two times with acetone, one time with pure water, and one time with IPA. Ultrasonic cleaning was performed once, and the above-mentioned ultrasonic cleaning was performed for 10 minutes at a time.

[0432] Thereafter, the sweetfish hooks after ultrasonic cleaning were dried at 60° C. for 30 minutes, and dipped in a 1 M-sodium silicate aqueous solution at room temperature for 30 minutes.

[0433] After the treatment with the sodium silicate aqueous solution, the sodium silicate aqueous solution was sufficiently washed with pure water to remove the sodium silicate aqueous solution, further washed with IPA, and dried at 60° C. for 30 minutes.

[0434] Next, after immersing in a surface treatment composition (SAMLAY (registered trademark), manufactured by Nippon Soda Co., Ltd.) for 30 minutes, wash with n-decane, and dry...

Embodiment 3

[0436] Put 100 nickel-plated sweetfish hooks (XP AIR SPEED, size: 6.5) in a glass container, and perform ultrasonication 4 times with toluene, 2 times with acetone, 1 time with pure water, and 1 time with IPA For cleaning, the above-mentioned ultrasonic cleaning was performed for 10 minutes at a time.

[0437] Thereafter, the sweetfish hooks after ultrasonic cleaning were dried at 60° C. for 30 minutes, and dipped in a 1 M-sodium silicate aqueous solution at room temperature for 30 minutes.

[0438] After the treatment with the sodium silicate aqueous solution, the sodium silicate aqueous solution was sufficiently washed with pure water to remove the sodium silicate aqueous solution, further washed with IPA, and dried at 60° C. for 30 minutes.

[0439] Next, using nonafluorohexyltrimethoxysilane, after immersing in the surface treatment composition prepared by the method described in Patent No. 4995467 for 30 minutes, wash with HFE-7300 (manufactured by Sumitomo 3M Co., Ltd.)....

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com