Nitrogen-enriched carbon shell cladded nano core-shell-structure carbonaceous carrier as well as preparation method and application thereof

A nano-core-shell and carbonaceous technology, applied in the field of electrochemical energy, can solve the problem that the cycle life of lithium-sulfur batteries cannot meet the requirements of industrialization, and achieve excellent physical and chemical adsorption capabilities of strong polysulfide ions, maintain high capacity, The effect of easy scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] In some preferred embodiments, the preparation method includes: carbonizing the precursor at a temperature of 100°C to 500°C. Further, the carbonization treatment time adopted is 12h-24h.

[0049] One aspect of the present invention provides a sulfur-carbon composite material, comprising:

[0050] The nano-core-shell structure carbonaceous carrier coated with nitrogen-rich carbon shell;

[0051] And, the sulfur loaded on the carbonaceous carrier;

[0052] Wherein, the sulfur-carbon composite material contains 50-90 wt% sulfur (mass percentage).

[0053] One aspect of the present invention provides a method of making the sulfur-carbon composite material, comprising:

[0054] Coating at least one carbon material with a nitrogen-containing polymer to form a precursor with a core-shell structure;

[0055] The precursor is uniformly mixed with sulfur, and carbonized in a protective atmosphere to form the sulfur-carbon composite material.

[0056] In some embodiments, th...

Embodiment 1

[0071] Example 1: Preparation of nitrogen-rich carbon shell precursor materials (NCNT@NCS and NG-NCNT@NCS)

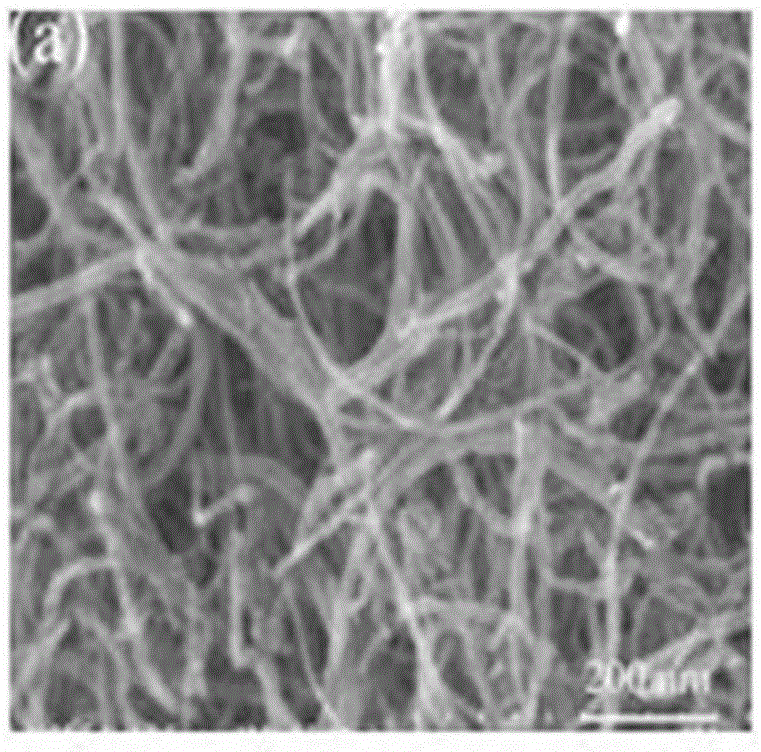

[0072] Concentrated acid (volume ratio H 2 SO 4 :HNO 3 =3:1) to treat carbon nanotubes (CNTs), and then nitrogen-doped carbon nanotubes (NCNTs) with a nitrogen content of 0.62at% by feeding ammonia gas under the temperature condition of 750°C for nitriding treatment. Weigh 100 mg of NCNT and ultrasonically disperse it in ultrapure water, slowly add 150 mg of aniline (ANI) solution dropwise, and adjust the pH value to between 1 and 2 with hydrochloric acid. Under ice-water bath conditions, an appropriate amount of ammonium persulfate was slowly added dropwise and stirred for 24 hours. After the reaction was completed, the mixture was filtered, washed, and vacuum-dried to obtain a PANI-coated NCNT material (NCNT@PANI), which is a one-dimensional nitrogen-rich nanomaterial.

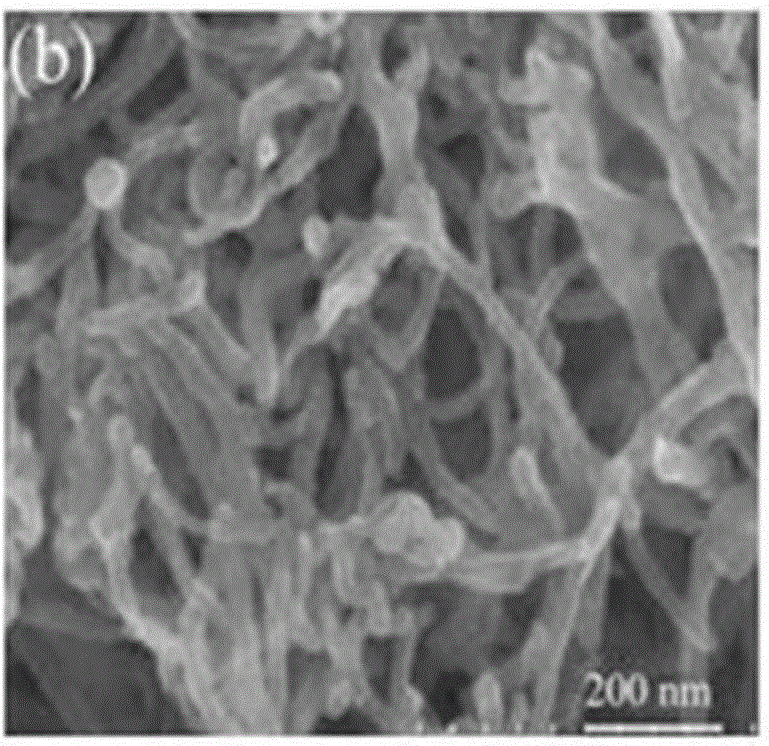

[0073] Introduce nitrogen-doped graphene to disperse ultrasonically with NCNT in a certain prop...

Embodiment 2

[0076] Example 2: Preparation and Characterization of Low Temperature Carbonization of Nitrogen-rich Carbon Shell PANI Coated Carbon-rich Nano

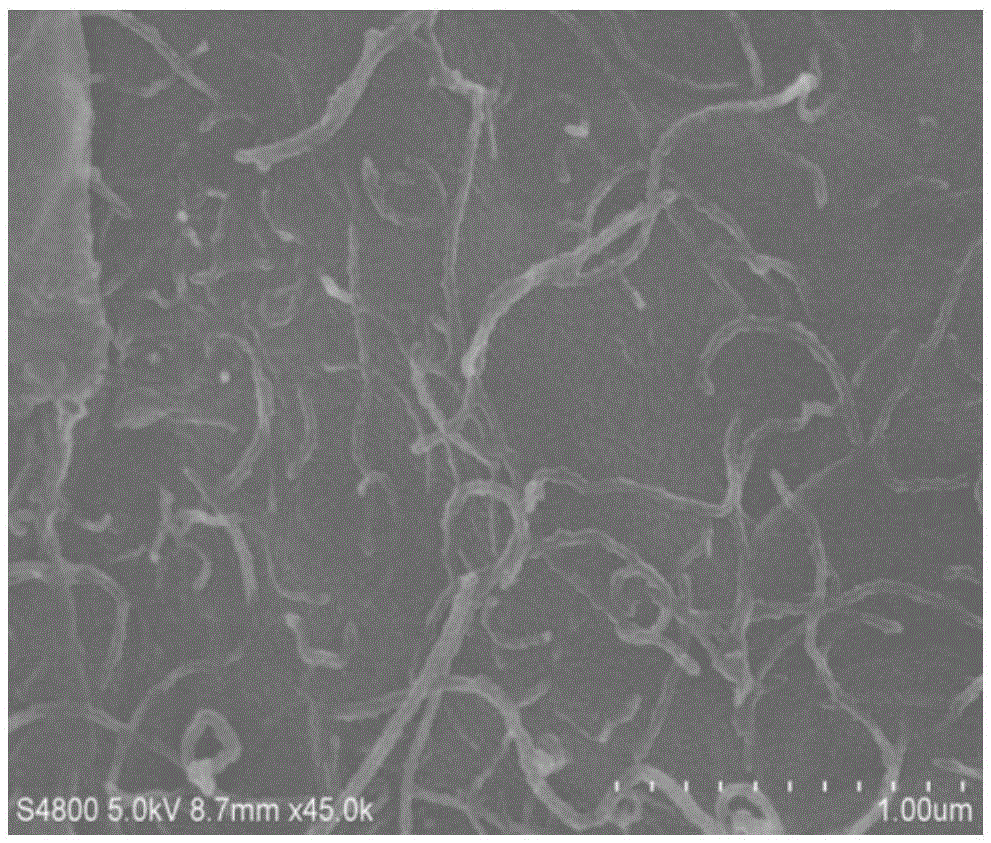

[0077] Under the protection of argon, the one-dimensional nitrogen-enriched nanomaterial (NCNT@PANI) obtained in Example 1 was first carbonized at 155° C. for 12 hours, and then carbonized at 180° C. for 12 hours to obtain the carbon nanomaterial ( NCNT@NCS), its nitrogen content is 11.1 at%.

[0078] Three-dimensional nano-nitrogen-rich nanomaterials (NG-NCNT@PANI) were subjected to low-temperature carbonization under the same conditions to obtain nitrogen-rich nano-carbon materials (NG-NCNT@NCS), whose nitrogen content was as high as 12.6 at%.

[0079] From figure 2 It can be seen from the Raman spectrum shown that after coating with PANI, both NCNT@PANI and NG-NCNT@PANI can display the peak of PANI at wavenumbers 1402 and 1235. After low-temperature carbonization treatment, the characteristic peaks of PANI are all weakened or ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com