Preparation method and application of sulfur-doped polyacrylonitrile-chlorella derived carbon compound sodium ion battery negative electrode material

A sulfur polyacrylonitrile, sodium ion battery technology, applied in battery electrodes, active material electrodes, secondary battery manufacturing, etc., can solve problems that have not been reported in the literature, and achieve the effects of inhibiting dissolution, simple operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Blend 0.5 g of anhydrous tin dichloride, 0.5 g of polyacrylonitrile, 0.23 g of chlorella and 10 mL of N-N dimethylformamide, and magnetically stir for 24 h to obtain a uniform spinning solution. ;

[0029] (2) Take the spinning solution prepared in the above step (1) in the syringe, set the spinning voltage to 23 kV, the plug flow rate to 0.3 mL / h, the receiving distance to 15 cm, and the temperature to 40 o C, PAN / SnCl prepared by electrospinning 2 carbon composite fibers;

[0030] (3) Place the composite fiber prepared in the above step (2) and a certain amount of sulfur powder in a tube furnace at a mass ratio of 1:5. Under an Ar atmosphere, with a gas flow rate of 80 mL / min, 5 oC / min rate of heating at 470 o C Calcination time 1 h, that is, sulfur-doped polyacrylonitrile-chlorella derived carbon composite;

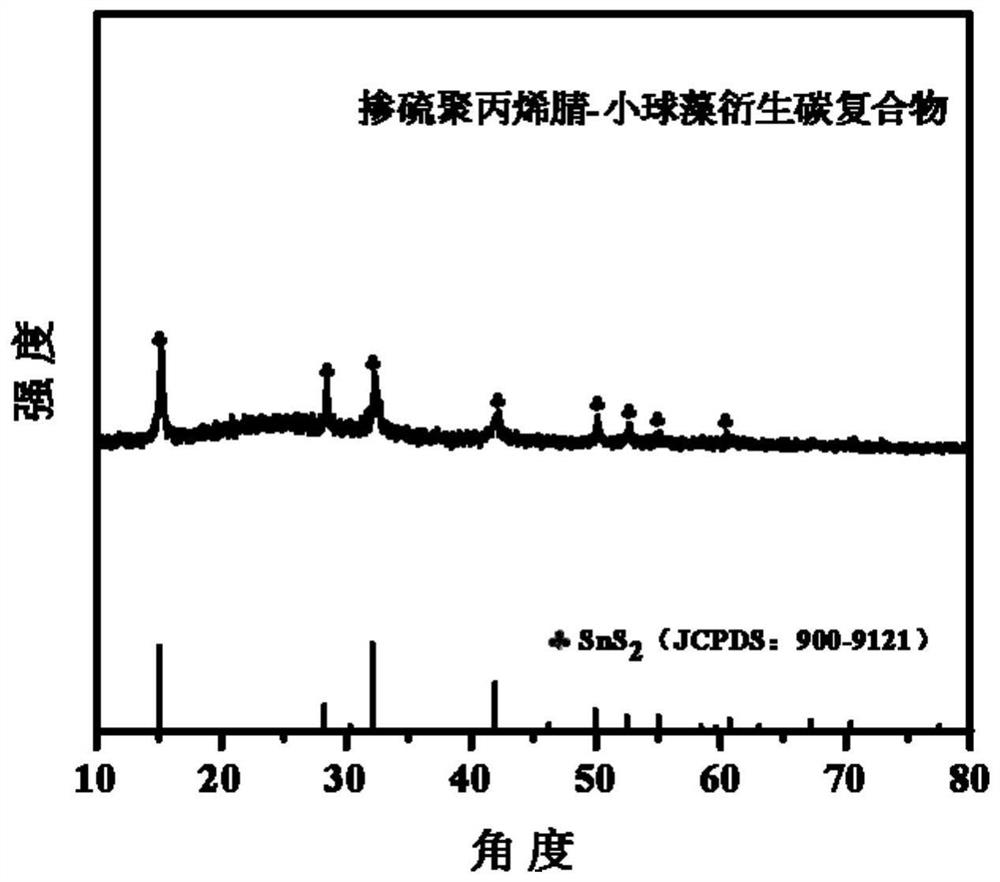

[0031] attached figure 1 It is the XRD pattern of sulfur-doped polyacrylonitrile-chlorella-derived carbon composite, from which the diffraction peak ...

Embodiment 2

[0034] (1) Blend 1 g of anhydrous tin dichloride, 1 g of polyacrylonitrile, 0.6 g of chlorella and 20 mL of N-N dimethylformamide, and magnetically stir for 24 h to obtain a uniform spinning solution for later use ;

[0035] (2) Take the spinning solution prepared in the above step (1) in the syringe, set the spinning voltage to 23 kV, the plug flow rate to 0.5 mL / h, the receiving distance to 15 cm, and the temperature to 35 o C, PAN / SnCl prepared by electrospinning 2 carbon composite fibers;

[0036] (3) Place the composite fiber prepared in the above step (2) and a certain amount of sulfur powder in a tube furnace at a mass ratio of 1:5, and in an Ar atmosphere, with a gas flow rate of 60 mL / min, 2 oC / min rate of heating at 450 o C Calcination time 1 h, that is, sulfur-doped polyacrylonitrile-chlorella derived carbon composite;

[0037] The sulfur-doped polyacrylonitrile-chlorella-derived carbon composite prepared in this example is used as the active component of the ...

Embodiment 3

[0039] (1) Blend 10 g of tin sulfate, 10 g of polyacrylonitrile, 8 g of chlorella, and 50 mL of N-N dimethylformamide, and magnetically stir for 24 h to obtain a uniform spinning solution for later use;

[0040] (2) Take the spinning solution prepared in the above step (1) in the syringe, set the spinning voltage to 25 kV, the plug flow rate to 0.6 mL / h, the receiving distance to 18 cm, and the temperature to 40 o C, PAN / SnCl prepared by electrospinning 2 carbon composite fibers;

[0041] (3) Place the composite fiber prepared in the above step (2) and a certain amount of sulfur powder in a tube furnace at a mass ratio of 1:5. Under an Ar atmosphere, with a gas flow rate of 80 mL / min, 5 oC / min rate of heating at 500 o C Calcination time 1 h, that is, sulfur-doped polyacrylonitrile-chlorella derived carbon composite;

[0042] The sulfur-doped polyacrylonitrile-chlorella-derived carbon composite prepared in this example is used as the active component of the negative electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com