A polymer modified composite positive electrode for lithium-sulfur battery and preparation method thereof

A lithium-sulfur battery and composite cathode technology, applied in battery electrodes, lithium storage batteries, electrode manufacturing, etc., to achieve the effects of easy transmission, large specific surface area, and inhibition of shuttle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

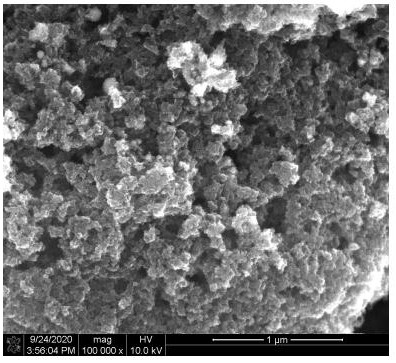

[0033] Example 1 Preparation of Porous Carbon A Using Fructose as Carbon Source

[0034] Mix 6.11345g 1-butyl-3-methylimidazolium chloride ([Bmim]Cl) with 5.577g ferric chloride (FeCl 3 ) mixed, fully stirred and mixed with a magnetic stirrer, and centrifuged in a high-speed centrifuge to remove insoluble matter to obtain an ionic liquid ([Bmim]FeCl 4 ), and the temperature was kept at 80 °C in an electric constant temperature blast drying oven for 12 hours.

[0035] Add 2 g of fructose to 5 mL of the above ionic liquid, stir for 2 h with a magnetic stirrer until the fructose is fully dissolved, transfer the mixture into a 25 mL high-temperature reaction kettle, and keep it in an oven at 180 ° C for 8 h to obtain carbon aerogels. The obtained carbon aerogel was washed five times with a mixed solvent of ethanol and acetone to wash away excess ionic liquid, and the sample was treated with 0.5M dilute hydrochloric acid to remove residual Fe and then fully dried to obtain a porou...

Embodiment 2

[0037] Example 2 Preparation of Porous Carbon B Using Fructose as Carbon Source

[0038] Mix 8.7335g 1-butyl-3-methylimidazolium chloride ([Bmim]Cl) with 8.11g ferric chloride (FeCl 3) mixed, fully stirred and mixed with a magnetic stirrer, and centrifuged in a high-speed centrifuge to remove insoluble matter to obtain an ionic liquid ([Bmim]FeCl 4 ), and the temperature was kept at 80 °C in an electric constant temperature blast drying oven for 12 hours.

[0039] Add 3 g of fructose to 10 mL of the above ionic liquid, stir for 3 h with a magnetic stirrer until the fructose is fully dissolved, transfer the mixture into a 25 mL high-temperature reaction kettle, and keep it in an oven at 180 ° C for 10 h to obtain a carbon airgel. The obtained carbon aerogel was washed five times with a mixed solvent of ethanol and acetone to wash away excess ionic liquid, and the sample was treated with 0.5M dilute hydrochloric acid to remove residual Fe and then fully dried to obtain a porous...

Embodiment 3

[0041] The preparation of embodiment 3 sulfur-carbon composite material A

[0042] Take 100mg of porous carbon A prepared in Example 1 and mix evenly with 200mg of sublimated sulfur, heat the mixture to 155°C under vacuum and keep it for 10h to obtain sulfur-carbon composite material A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com