Porous silicon composite negative electrode material and preparation method thereof

A negative electrode material, porous silicon technology, applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc., can solve the problem of inability to carry out large-scale promotion, increase production requirements and difficulties, porous structure is easy to be destroyed, etc. problems, to achieve the effect of improving cycle stability, good cycle performance, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0080] The present invention also provides a method for preparing a porous silicon composite negative electrode material, comprising the following steps:

[0081] (1) Coating the porous silicon substrate with the first conductive material precursor, and then treating it at 400-1600° C. for 5-10 hours to obtain the first precursor;

[0082] The first conductive material precursor includes a conductive carbon material precursor, a mixture of a conductive carbon material precursor and an alloy material precursor, or an alloy material precursor;

[0083] The coating includes emulsification coating, liquid phase coating, gas phase coating or solid phase coating;

[0084] (2) Composite the first precursor with the nano-silicon-based raw material, and then treat it at 400-1600°C for 5-10 hours to obtain a porous silicon composite negative electrode material;

[0085] The nano-silicon-based raw material includes a silicon source, or a mixture of a silicon source and other raw materia...

Embodiment 1

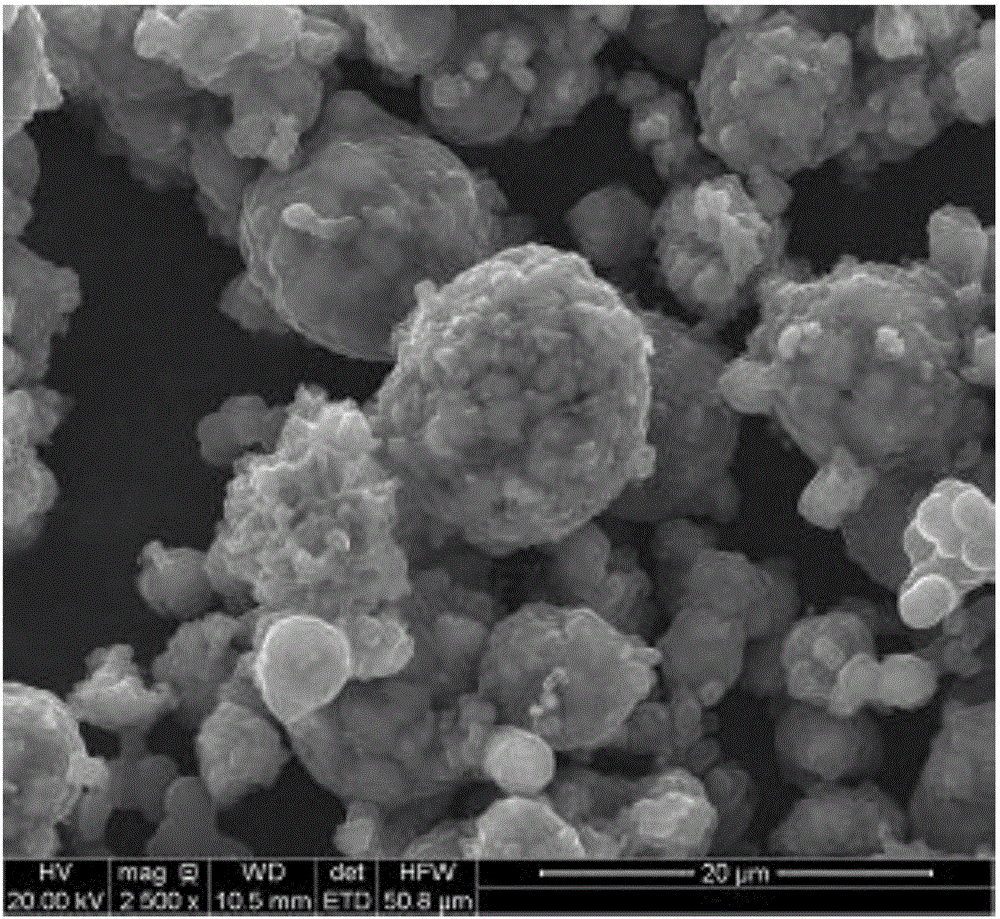

[0133] Disperse porous silicon in a solvent containing grapes, wherein the mass ratio of porous silicon to glucose is 1:1, and the specific surface area of porous silicon is 40cm 2 / g, the average particle size is 13 μm. After the dispersion is uniform, carry out spray drying, the air inlet temperature is 200°C, the air outlet temperature is 100°C, the rotation speed of the dispersion disc is 2000r / min, and then carbonized at 800°C for 5 hours in a nitrogen atmosphere, and then cooled to room temperature to obtain coating cracking The porous silicon material of carbon is the first precursor.

[0134] Place the porous silicon material coated with pyrolysis carbon in a rotary furnace, raise the temperature to 500°C under the high-purity nitrogen flow rate of 5.0L / min, and then change the high-purity nitrogen into high-purity hydrogen and SiH 4 The mixed gas, the flow rate remains unchanged, when the mass ratio of the silane gas and the first precursor is 1:1, the gas is chang...

Embodiment 2 and 3

[0136] The experimental steps in Examples 2 and 3 are the same as in Example 1, only the mass ratio of porous silicon to glucose and the mass ratio of the first precursor to silane are changed. The mass ratio of porous silicon to glucose in Example 2 is 2:1, the mass ratio of the first precursor to silane is 2:1; the mass ratio of porous silicon to glucose in Example 3 is 2:5, the first precursor The mass ratio to silane is 2:5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com