Praseodymium activated lead fluoride scintillation crystal material and preparation method thereof

A scintillation crystal, lead fluoride technology, applied in the direction of polycrystalline material growth, chemical instruments and methods, crystal growth, etc., can solve problems such as the inability to use dual-read calorimeters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 Crucible descending method grows Pr 0.005 PbF 2.015 the crystal

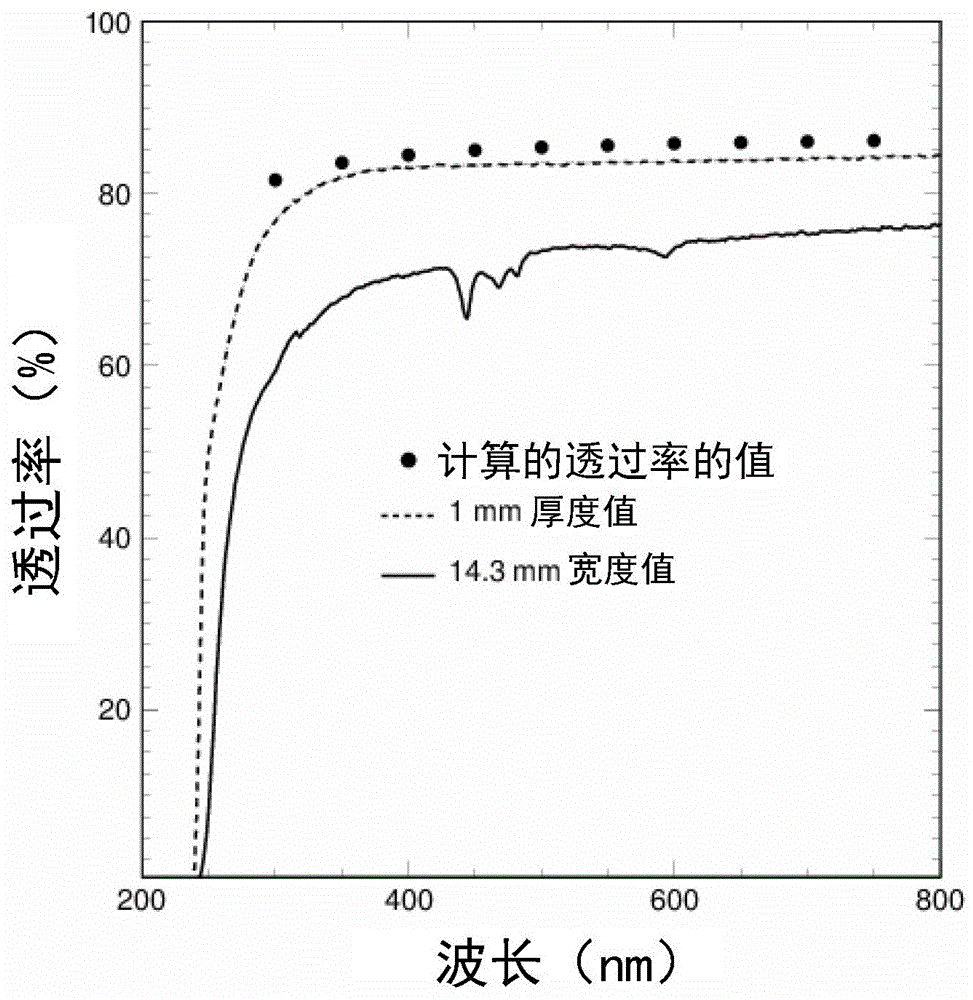

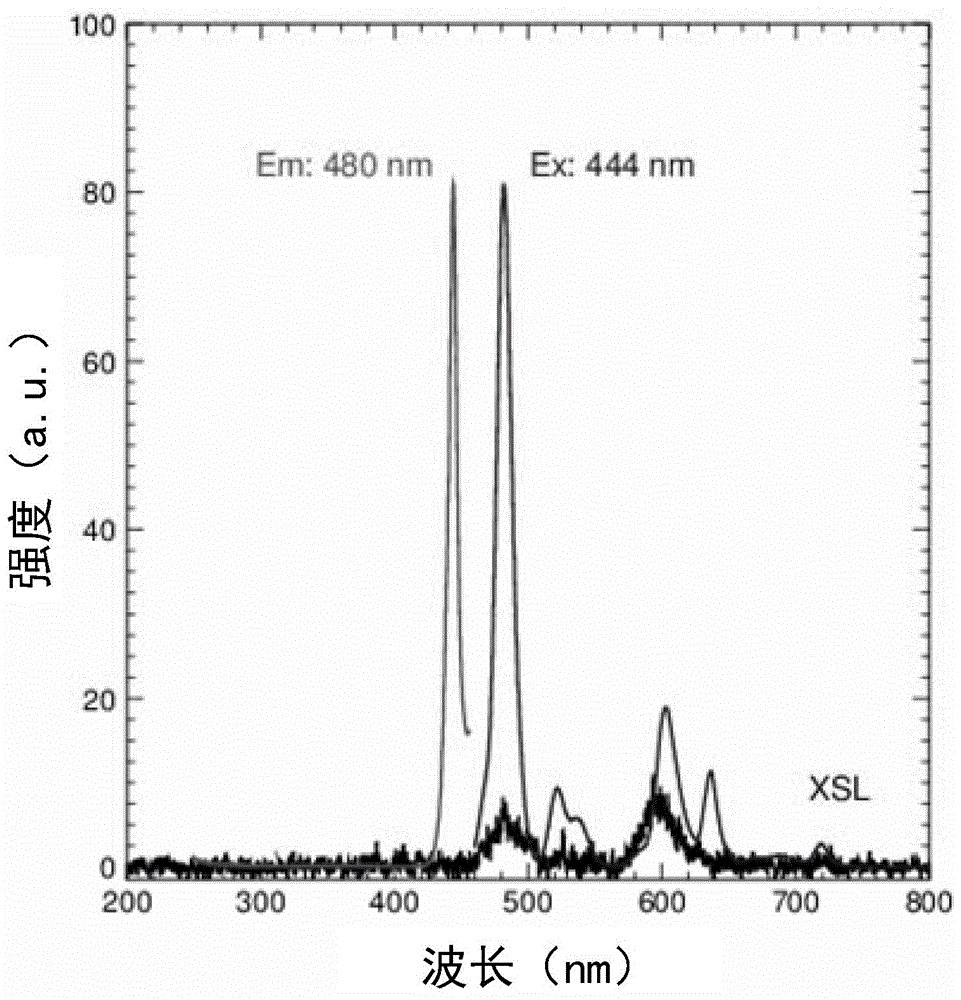

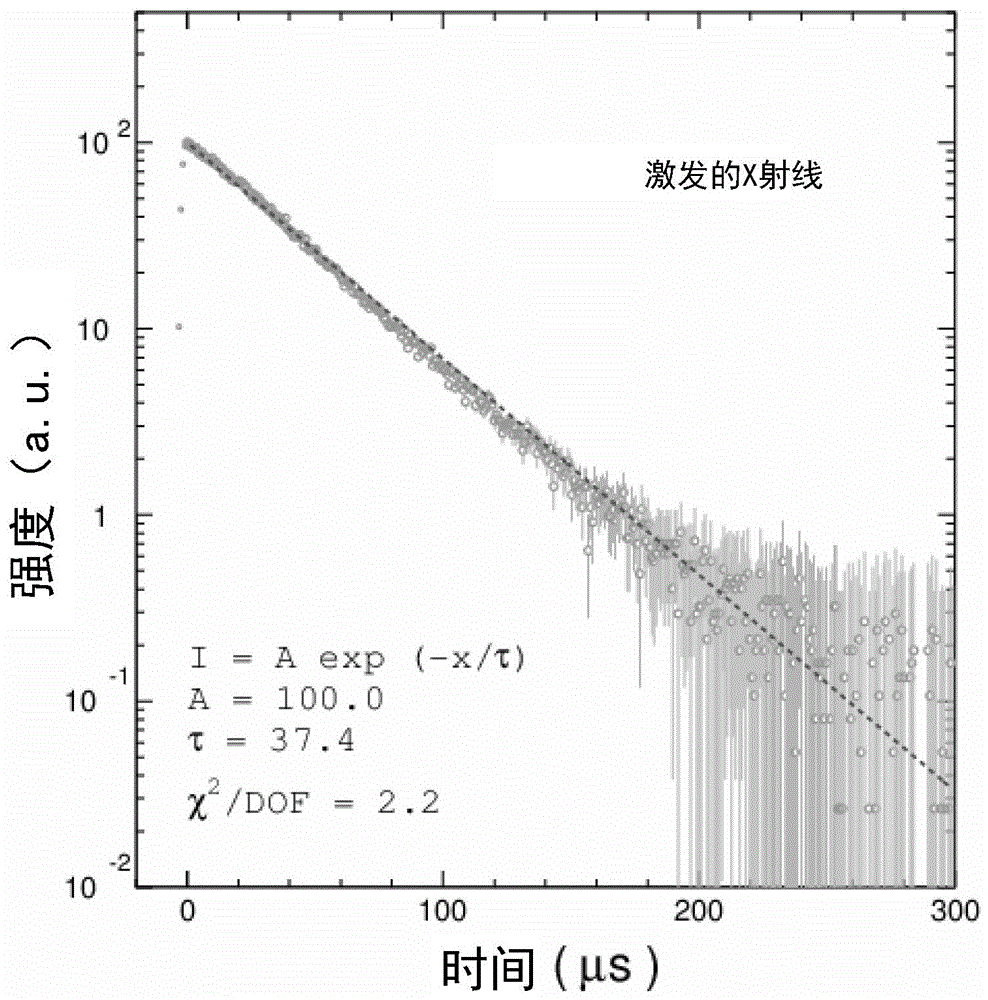

[0035] PrF with a purity of 99.99% 3 and PbF 2 According to molecular formula Pr 0.005 PbF 2.015 The ratio is accurately weighed, and the total mass of raw materials is 500 grams; the raw materials are fully mixed and dried in a vacuum oven at 200°C for 10 hours; the dried raw materials are transferred into a 20×20×200mm In a platinum crucible, seal the crucible; place the crucible in a descending growth furnace, then control the growth furnace to heat up at a rate of 30°C / min until the temperature of the platinum crucible is 890°C, and keep it warm for 5 hours; crystal growth solid-liquid interface The temperature gradient is set to 35°C / cm; the crucible is slowly lowered at a speed of 2mm / hour; after the crystal growth is completed, the temperature is slowly lowered to room temperature at 30°C / hour. Cut, grind and polish the grown crystal into a 14.3×14.3×1 mm crystal sample. Its tra...

Embodiment 2

[0036] Embodiment 2 crucible descending method grows Pr 0.01 PbF 2.03 the crystal

[0037] PrF with a purity of 99.99% 3 and PbF 2 According to molecular formula Pr 0.01 PbF 2.03 Proportioning is accurately weighed, and the total mass of raw materials is 500 grams; the raw materials are fully mixed and then dried in a vacuum oven at 200°C for 30 hours; the dried PrF 3 and PbF 2Under the protection of dry Ar, it is transferred into a platinum crucible with a size of 20 × 20 × 200mm, and the crucible is sealed; the crucible is placed in a descending method growth furnace, and then the growth furnace is controlled to heat up at a rate of 30°C / min until the platinum crucible The temperature was 890°C and kept for 5 hours; the temperature gradient of the solid-liquid interface for crystal growth was set at 30°C / cm; the crucible was slowly lowered at a speed of 2mm / hour; after the crystal growth was completed, the temperature was slowly lowered at 30°C / hour to room temperature...

Embodiment 3

[0038] Embodiment 3 The crucible descending method grows Pr 0.0005 PbF 2.0015 the crystal

[0039] PrF with a purity of 99.99% 3 and PbF 2 According to molecular formula Pr 0.0001 PbF 2.0015 Proportioning is accurately weighed, and the total mass of raw materials is 500 grams; the raw materials are fully mixed and then dried in a vacuum oven at 200°C for 30 hours; the dried PrF 3 and PbF 2 Under the protection of dry Ar, it is transferred into a platinum crucible with a size of 20 × 20 × 200mm, and the crucible is sealed; the crucible is placed in a descending method growth furnace, and then the growth furnace is controlled to heat up at a rate of 30°C / min until the platinum crucible The temperature was 890°C and kept for 5 hours; the temperature gradient of the solid-liquid interface for crystal growth was set at 35°C / cm; the crucible was slowly lowered at a speed of 2mm / hour; after the crystal growth was completed, the temperature was slowly lowered at 30°C / hour to roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com