Halogen-free resin composition, adhesive and laminated busbar insulating adhesive film prepared therefrom, and preparation method of insulating adhesive film

A technology of resin composition and insulating film, applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesives, insulators, etc., can solve the problems such as the limitation of the use of halogen-containing products, and achieve excellent high temperature peel strength, excellent heat resistance high temperature adhesion, good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A halogen-free resin composition, comprising 40 parts by mass of saturated polyester resin B (L952), 5 parts of thermoplastic phenolic resin, 3 parts of aliphatic isocyanate curing agent, phosphorus-containing flame retardant (OP-935) 30 parts, filler (aluminum hydroxide) 5 parts, antioxidant (168) 0.3 part, coupling agent (KH570) 0.8 part.

[0038] The halogen-free resin composition is applied to an insulating adhesive film for a laminated busbar.

[0039] The preparation method of the insulating adhesive film for laminated busbars containing the halogen-free resin composition: first use cyclohexanone to adjust the composition of the saturated polyester resin B, thermoplastic phenolic resin, aliphatic isocyanate curing agent, phosphorus-containing flame retardant, A liquid dispersion (with a solid content of 40wt%) composed of a filler, an antioxidant and a coupling agent is mixed to form a flame-retardant adhesive.

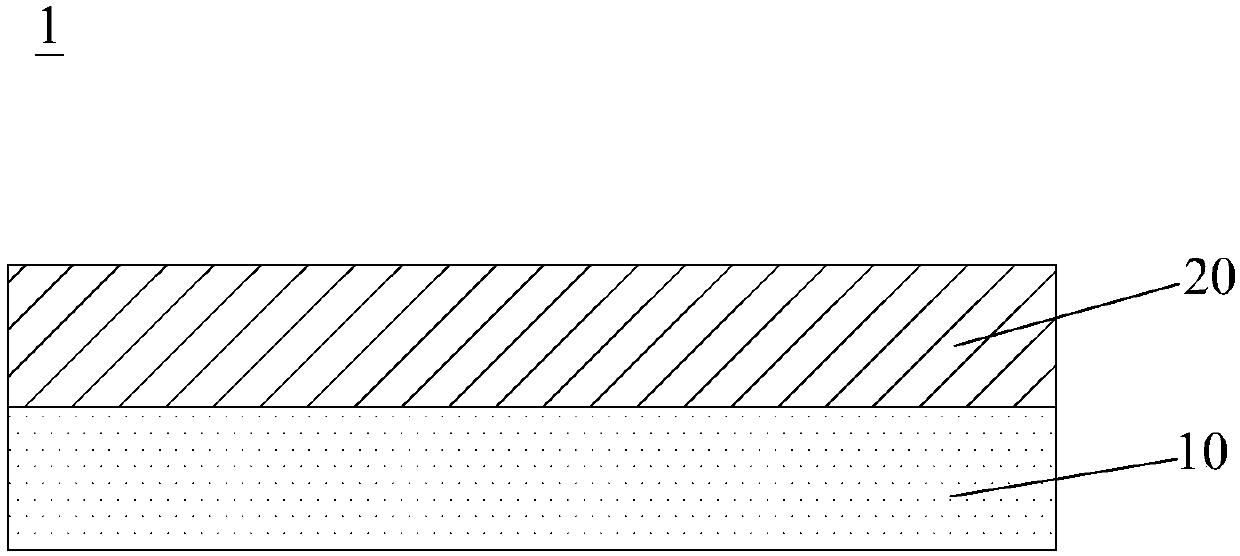

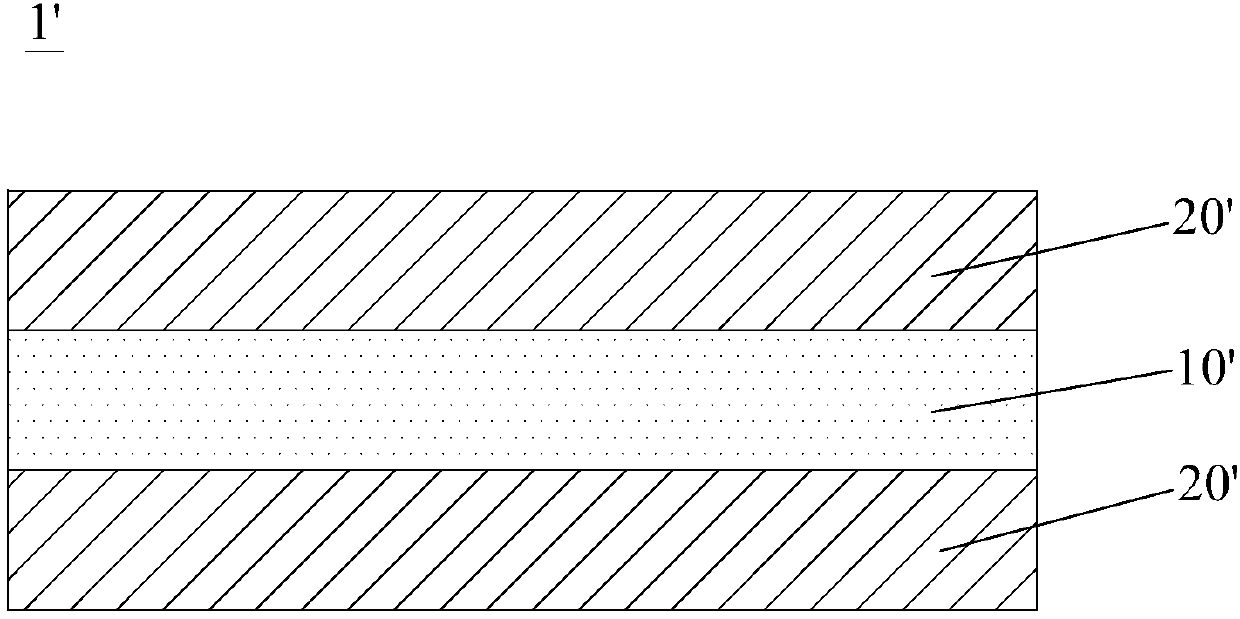

[0040] Such as figure 1 As shown, the flame-reta...

Embodiment 2

[0044] A halogen-free resin composition, comprising 5 parts of saturated polyester resin A (S1611), 75 parts of saturated polyester resin B (ES120), 15 parts of thermosetting phenolic resin, and 20 parts of alicyclic isocyanate curing agent calculated in parts by mass parts, 80 parts of phosphorus-containing flame retardant (SPB-100), 20 parts of nitrogen-containing flame retardant (melapur MC15), 10 parts of filler (magnesium hydroxide), 0.1 part of antioxidant (1010), coupling agent (KH570 ) 0.08 parts.

[0045] The halogen-free resin composition is applied to the laminated busbar insulation adhesive film.

[0046] The preparation method of the insulating adhesive film for laminated busbars containing the halogen-free resin composition: first use acetone to adjust the composition of the saturated polyester resin A, saturated polyester resin B, thermosetting phenolic resin, alicyclic isocyanate curing agent, containing A liquid dispersion (solid content: 45wt%) composed of p...

Embodiment 3

[0051] A halogen-free resin composition, comprising 25 parts by mass of saturated polyester resin A (S1426), 40 parts of saturated polyester resin B (L912), 30 parts of thermoplastic phenolic resin, and 8 parts of aromatic isocyanate curing agent , phosphorus-containing flame retardant (SP-703H) 30 parts, nitrogen-containing flame retardant (melapur MC15) 40 parts, filler (silicon dioxide) 20 parts, antioxidant (1010) 0.5 parts, coupling agent (TMC- 311) 0.2 parts.

[0052] The halogen-free resin composition is used for an insulating adhesive film for a laminated busbar.

[0053] The preparation method of the insulating adhesive film for laminated busbars containing the halogen-free resin composition: first use ethyl acetate to adjust the composition of the saturated polyester resin A, saturated polyester resin B, thermoplastic phenolic resin, aromatic isocyanate curing agent, A liquid dispersion (with a solid content of 50 wt%) composed of a phosphorus-containing flame retar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com