Core-shell ceramic microspheres and preparation method thereof

A ceramic microsphere, core-shell technology, applied in the field of SiO2/SiCN core-shell ceramic microsphere and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

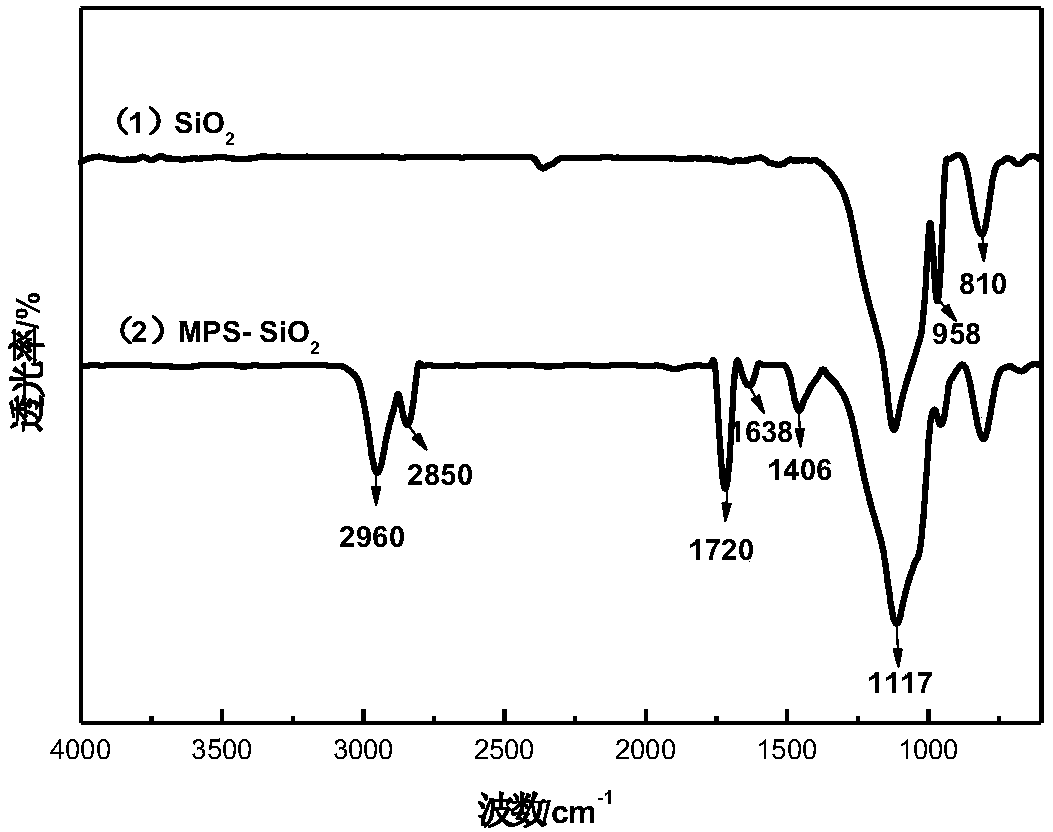

[0035] Add 0.5 g of silicon dioxide and 5 mL of absolute ethanol into the three-necked flask, and put it into an ultrasonic instrument for sufficient ultrasonic dispersion for 15 minutes. Add 0.5 mL of silane coupling agent MPS, and react in a water bath at 40° C. for 24 h. Centrifugal washing, drying. Disperse the modified silica in an aqueous phase system containing 0.1 g of emulsifier OP-100, 7.5 g of deionized water, and 7.5 g of acetonitrile, and add 1 g of polysilazane dropwise to the above aqueous phase system. 0.01ml per minute, ultrasonically dispersed to obtain a uniform emulsion, cross-linked and solidified in an autoclave at 160°C for 4 hours, after the reaction, it was centrifuged and washed three times, dried at 80°C, and then placed in a vacuum furnace for sintering. From room temperature 20 degrees Celsius, the temperature is raised to 1000 degrees Celsius at a rate of 5 degrees Celsius per minute and kept for 5 hours and then cooled to room temperature 20 deg...

Embodiment 2

[0037] Add 0.5 g of silicon dioxide and 5 mL of absolute ethanol into the three-necked flask, and put it into an ultrasonic instrument for sufficient ultrasonic dispersion for 15 minutes. Add 0.5 mL of silane coupling agent MPS, and react in a water bath at 40° C. for 24 h. Centrifugal washing, drying. Disperse the modified silicon dioxide in an aqueous phase system containing 0.2 g of emulsifier OP-100, 15 g of deionized water, and 15 g of acetonitrile, and add 2 g of polysilazane dropwise to the above aqueous phase system at a rate of Minute 0.05ml, ultrasonic dispersion to obtain a homogeneous emulsion, cross-linked and solidified in an autoclave at 200 ° C for 4 hours, after the reaction, it was centrifuged and washed three times, dried at 80 ° C, placed in a vacuum furnace for sintering, from room temperature Start at 25 degrees Celsius and heat up to 1600 degrees Celsius at a rate of 2 degrees Celsius per minute and keep it warm for 1 hour and then cool to room temperat...

Embodiment 3

[0039] Add 0.5 g of silicon dioxide and 5 mL of absolute ethanol into the three-necked flask, and put it into an ultrasonic instrument for sufficient ultrasonic dispersion for 15 minutes. Add 0.5 mL of silane coupling agent MPS, and react in a water bath at 40° C. for 24 h. Centrifugal washing, drying. Disperse the modified silicon dioxide in an aqueous phase system containing 0.2 g of emulsifier OP-10, 15 g of deionized water, and 15 g of acetonitrile, and add 2 g of polysilazane dropwise to the above aqueous phase system at a rate of 0.03ml per minute, ultrasonic dispersion to obtain a homogeneous emulsion, cross-linked and solidified in an autoclave at 200°C for 6 hours, after the reaction, it was centrifuged and washed three times, dried at 80°C, and then placed in a vacuum furnace for sintering. At room temperature of 20 degrees Celsius, the temperature is raised to 1200 degrees Celsius at a rate of 4 degrees Celsius per minute and kept for 3 hours, then cooled to room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com