Heat dissipation structure and processing technology of single tube igbt

A technology of heat dissipation structure and processing technology, which is applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., and can solve the problems that the ambient temperature of the coolant affects the structural design of the heat exchanger, reduces operating safety, and is not easy to clean. Achieve excellent in-plane thermal conductivity, improve longitudinal conductivity, and meet heat dissipation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with drawings and embodiments.

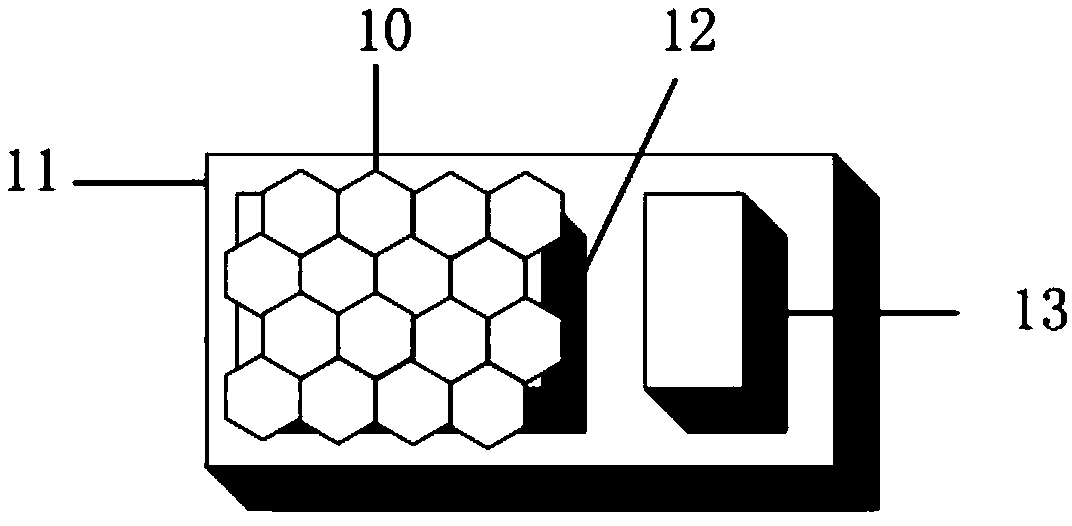

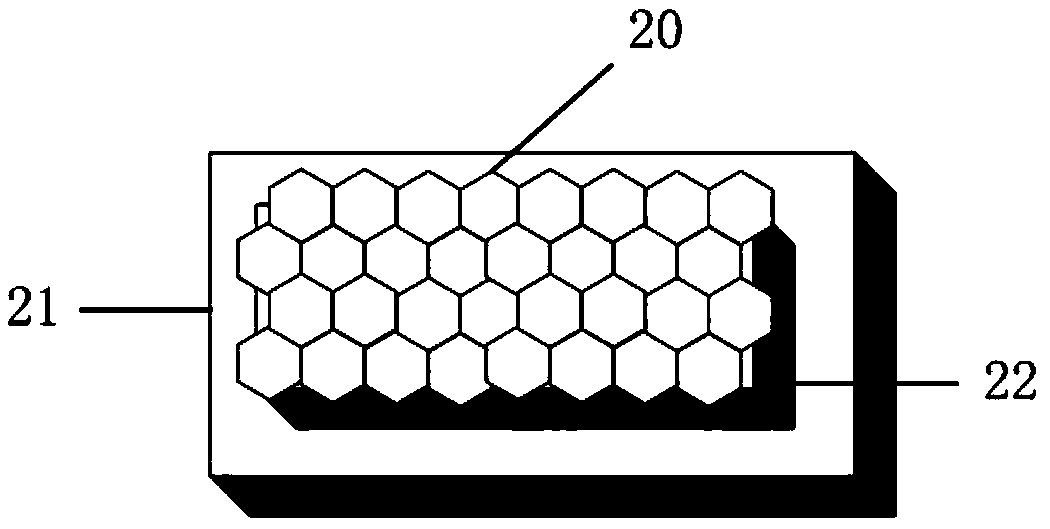

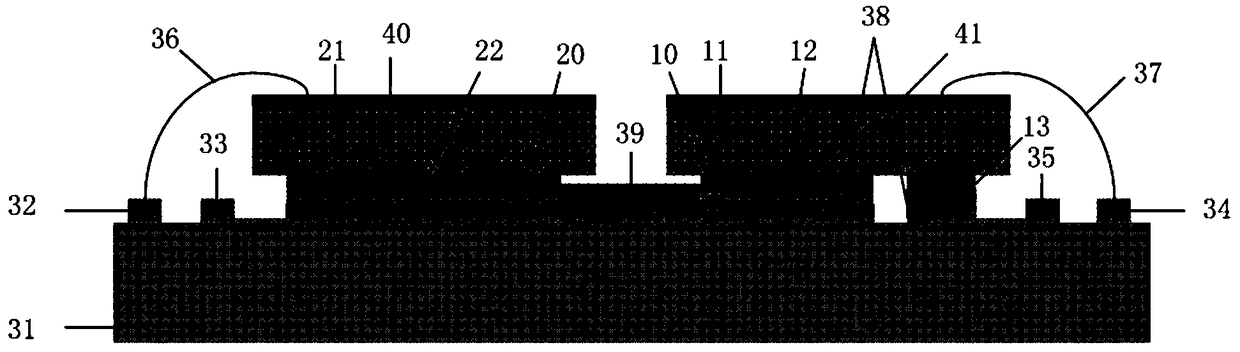

[0039] The invention proposes a heat dissipation structure of a single-tube IGBT, which generally includes a substrate, a chip, a heat sink, a graphene heat dissipation layer and a graphene-based interconnection material. Wherein the single-layer graphene film prepared by chemical vapor deposition is used as the heat dissipation layer for the fronts of the IGBT chip 11 and the FRD chip 21, see figure 1 and figure 2 . figure 1 The upper surface of the middle IGBT chip 11 has an IGBT chip emitter 12 and a gate 13 , and the upper surface of the IGBT chip emitter 12 is a first graphene thin film heat dissipation layer 10 . figure 2 The FRD chip emitter 22 is arranged on the upper surface of the middle FRD chip 21 , and the second graphene film heat dissipation layer 20 is formed on the upper surface thereof.

[0040] The few-layer graphene powder prepared by the redox ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com