Fully automatic hydraulic rock opening device

A fully automatic and hydraulic technology, applied in the field of hydraulic devices, can solve the problems of oil cylinders without dust-proof facilities, time-consuming and labor-intensive efficiency, and low safety factor, and achieve the effects of reducing dust pollution, reducing noise, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

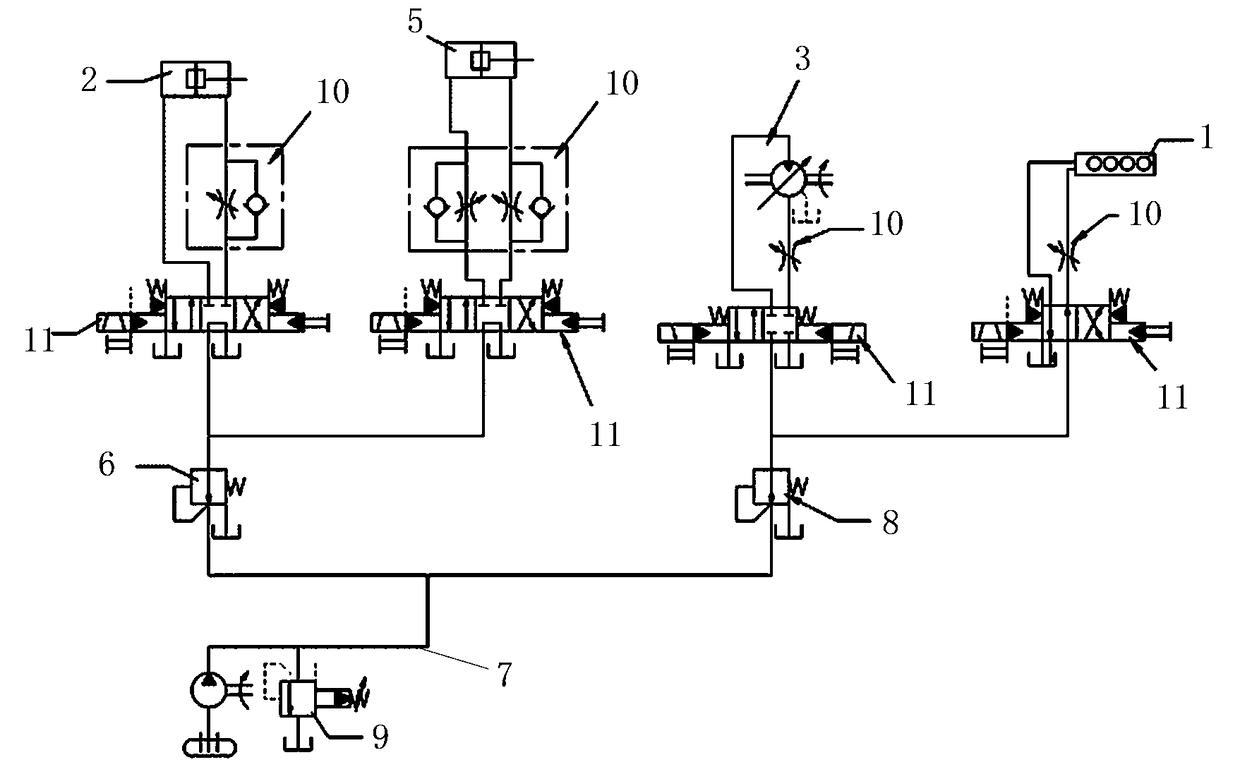

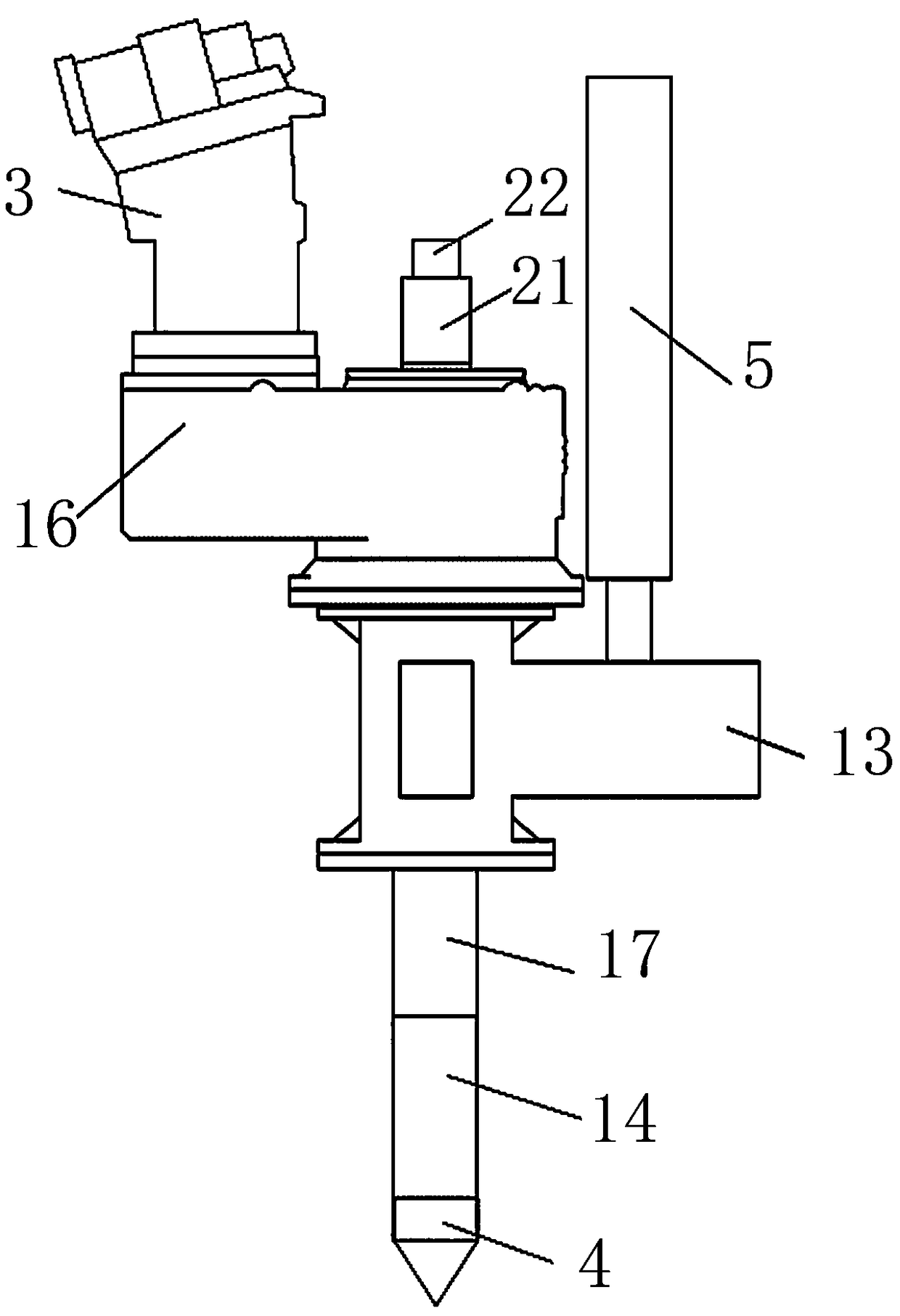

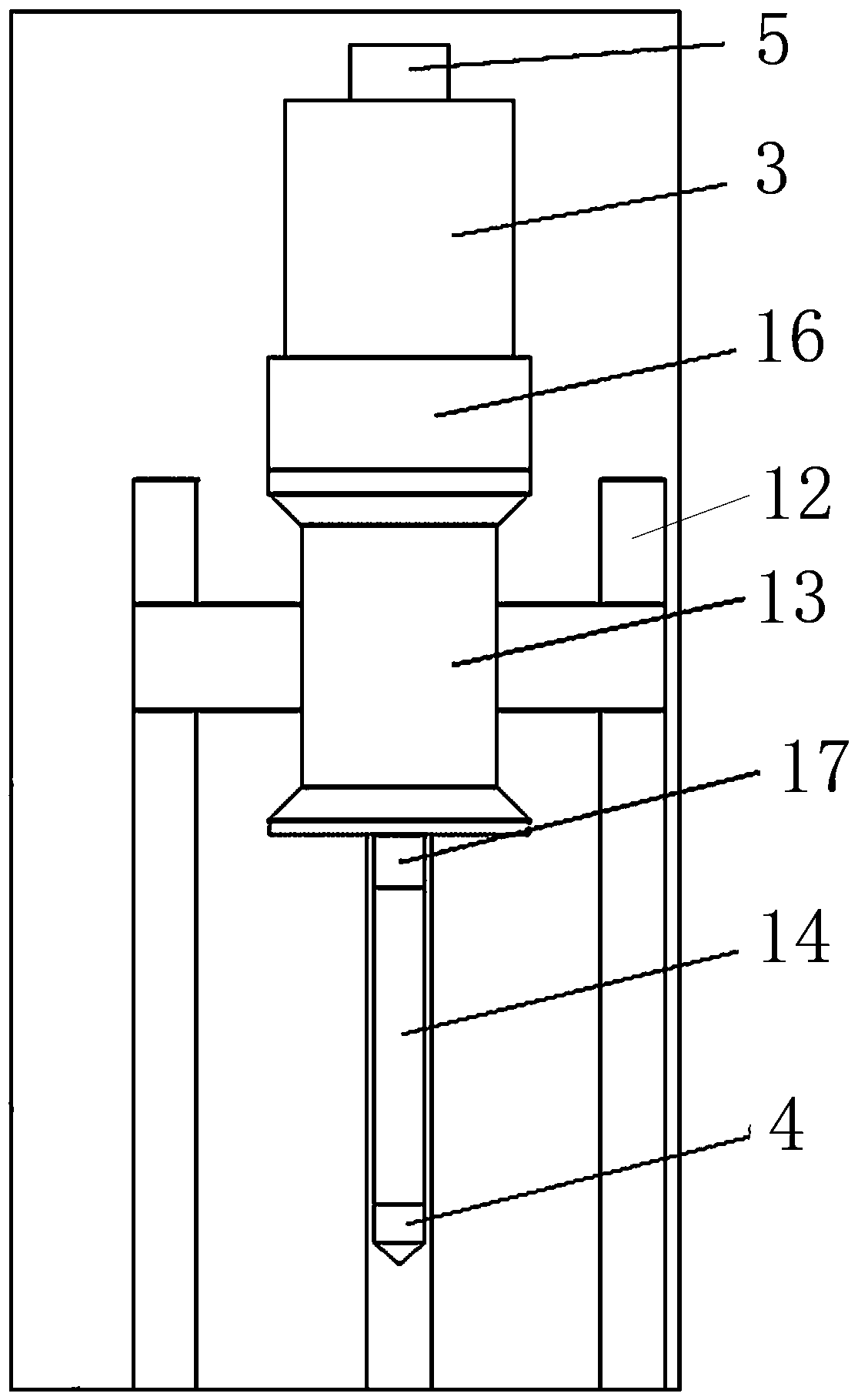

[0019] Such as figure 1 As shown, the fully automatic hydraulic rocking device includes a rocking part and a drilling part. The rocking part is mainly composed of a rocking expander 1 and a rocking hydraulic cylinder 2. The pistons of the rocking expander 1 and the rocking hydraulic cylinder 2 The rods are connected, and there is at least one open stone part. When there are multiple, the arrangement is linear arrangement, curved arrangement and linear and curved mixed arrangement. There are various combinations such as planar arrangement and spatial three-dimension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com