Method for inhibiting cemented carbide grain growth and ultra-fine grain cemented carbide preparation process

A cemented carbide, grain growth technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problem of inhibiting uneven distribution, achieve grain refinement, reduce speed and probability, improve hardness and bending resistance the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

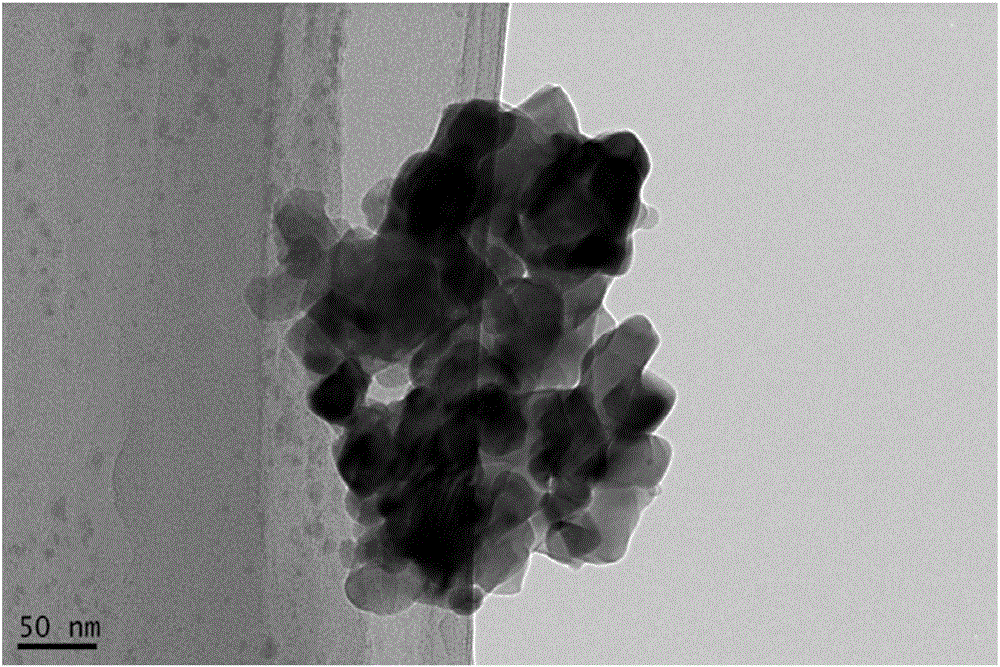

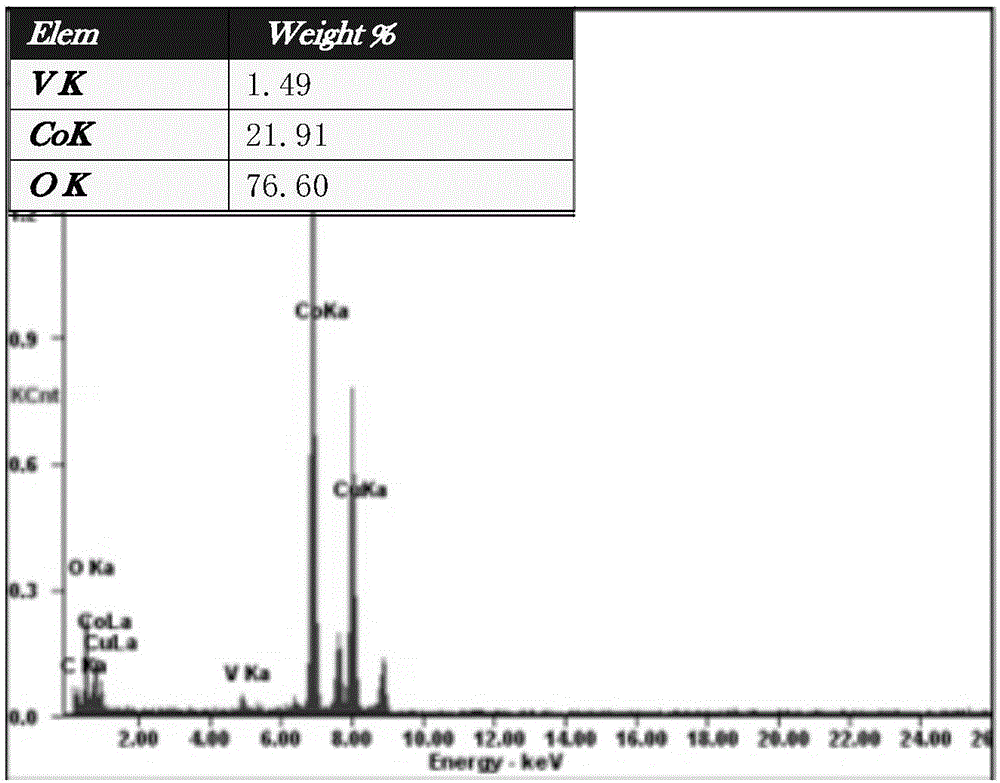

[0047] Step 1: Co. 3 o 4 -V 2 o 5 Preparation of Composite Nanopowders

[0048] Take 100gCoCl 2 and 4.65gNH 4 VO 3 Preparation of CoCl with a concentration of 0.4mol / L 2 , NH 4 VO 3 Add 0.44mol / L, same volume, same temperature oxalic acid solution to the resulting mixed solution and mix evenly, stir to produce precipitate; after 6 hours of aging, dry the precipitate and calcinate at 400°C for 4h to prepare Co 3 o 4 -V 2 o 5 Composite nanopowder; V 2 o 5 :Co 3 o 4 =1:35.87.

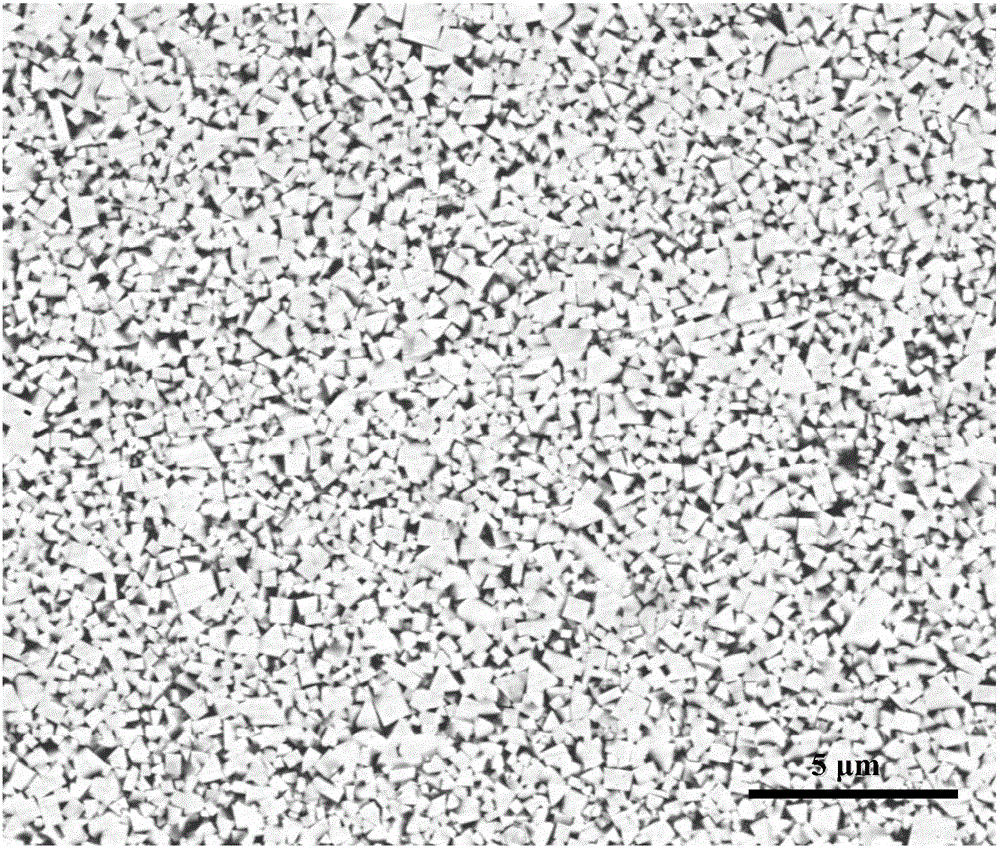

[0049] The second step: preparation of Co-VC composite structure nanopowder

[0050] Weigh Co according to the designed cemented carbide material composition ratio 3 o 4 -V 2 o 5 Composite nanopowder, C, where Co 3 o 4 -V 2 o 5 Composite nanopowder: C=2.7:1, mixing and ball milling to obtain a powder mixture; mold the alloy powder mixture in a mold to form a compact, and the molding pressure is 80MPa; place the compact in a vacuum atmosphere In-situ carbonization reaction, the rea...

Embodiment 2

[0055] Step 1: Co. 3 o 4 -V 2 o 5 Preparation of Composite Nanopowders

[0056] Take 100g of CoCl 2 and 2.99 g of NH 4 VO 3 Preparation of CoCl with a concentration of 0.6mol / L 2 , NH 4 VO 3 Add 0.72 mol / L oxalic acid solution of the same volume and temperature to the resulting mixed solution and mix evenly, stirring to produce a precipitate; after 6 hours of aging, the precipitate is dried and calcined at 400°C for 2 hours to prepare Co 3 o 4 -V 2 o 5 Composite nanopowder; V 2 o 5 :Co 3 o 4 =1:50.

[0057] The second step: preparation of Co-VC composite structure nanopowder

[0058] Weigh Co according to the designed cemented carbide material composition ratio 3 o 4 -V 2 o 5 Composite nanopowder, C, where Co 3 o 4 -V 2 o 5 Composite nanopowder: C=2.8:1, mixing and ball milling to obtain a powder mixture; molding the alloy powder mixture in a mold to form a compact, and the molding pressure is 100MPa; placing the compact in a vacuum atmosphere In-situ...

Embodiment 3

[0063] Step 1: Co. 3 o 4 -V 2 o 5 Preparation of Composite Nanopowders

[0064] Take 100g of CoCl 2 and 6.14 g of NH 4 VO 3 Preparation of CoCl with a concentration of 0.8mol / L 2 , NH 4 VO 3 Add 0.9 mol / L, same volume, same temperature oxalic acid solution to the obtained mixed solution and mix evenly, stir to produce precipitate; after 4 hours of aging, dry the precipitate and calcinate at 450°C for 4h to prepare Co 3 o 4 -V 2 o 5Composite nanopowder; V 2 o 5 :Co 3 o 4 =1:28.40.

[0065] The second step: preparation of Co-VC composite structure nanopowder

[0066] Weigh Co according to the designed cemented carbide material composition ratio 3 o 4 -V 2 o 5 Composite nanopowder, C, where Co 3 o 4 -V 2 o 5 Composite nanopowder: C=2.9:1, mixing and ball milling to obtain a powder mixture; mold the alloy powder mixture in a mold to form a compact, and the molding pressure is 150MPa; place the compact in a vacuum atmosphere In-situ carbonization reaction,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com