Nitride fluorescent powder and preparation method thereof

A technology of nitride phosphors and phosphors, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of low purity, poor anti-aging performance, and poor heat and humidity resistance of red fluorescent pink, and achieve long light decay time, Excellent high temperature resistance and high humidity resistance, excellent performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

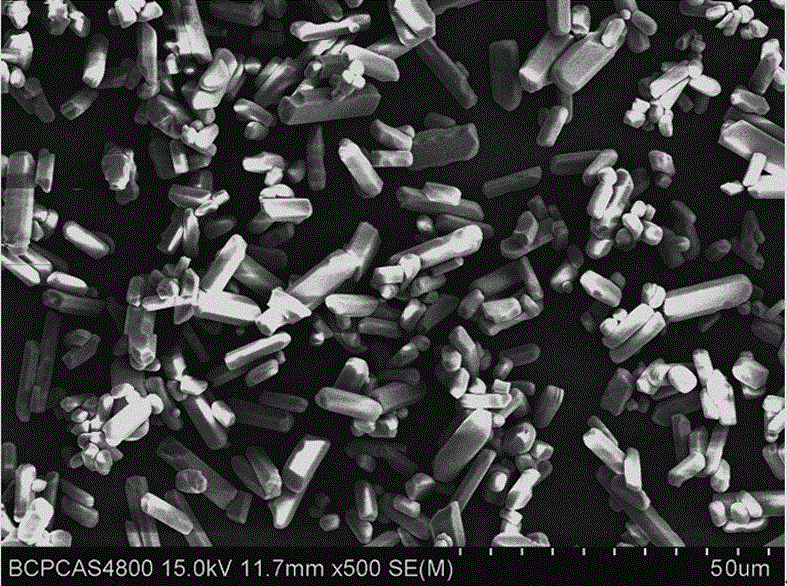

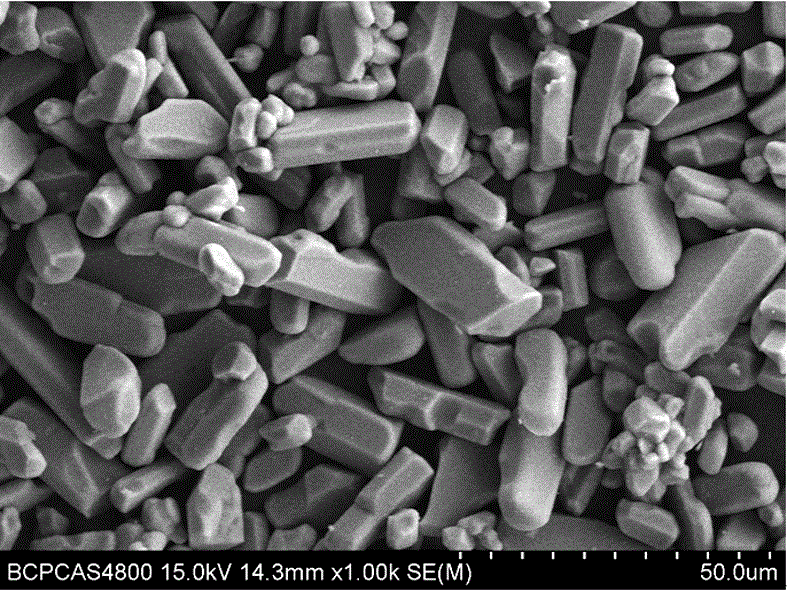

Image

Examples

Embodiment 1

[0037] According to Ca 0.992 AlMo 0.1 Si 0.9 N 3 : Eu 0.008 Stoichiometric ratio, weigh 0.331mol of Ca in an inert gas environment 3 N 2 , 1mol of AlN, 0.033mol of Mo 3 N 2 , 0.008mol of EuN and 0.3mol of Si 3 N 4 , and Ca 3 N 2 , AlN, Mo 3 N 2 , EuN purity are higher than 99.999%, D502 : MgF 2 :SrCl 2 =1:1:1 weigh BaCl 2 , MgF 2 and SrCl 2, and mixed evenly in denatured alcohol, then dried, and passed through a 300-mesh sieve to obtain a flux. The prepared flux was weighed, and the amount of the flux was 3wt% of the total mass of the above mixture. Mix the raw materials and flux in the air-flow mixer for 3 hours and then fill them in the molybdenum crucible, put the molybdenum crucible in another boron nitride crucible with a slightly larger diameter, and fill the SiC powder between the two crucibles , cover the crucible lid. Put this boron nitride crucible in a pressure furnace under H 2 The nitrogen-hydrogen mixture with a volume fraction of 5% is sinte...

Embodiment 2~22

[0041] The preparation methods of Examples 2-22 are the same as those of Example 1, except that the Mo content is changed.

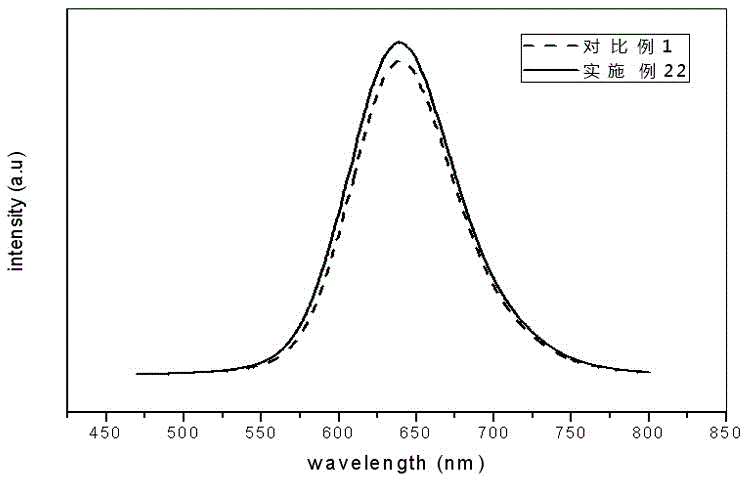

[0042] Table 1 shows the samples prepared in Examples 1-22 and Comparative Example 1 and their performance parameters.

[0043] Table 1

[0044] Example structural formula light intensity x color coordinate Peak wavelength / nm Particle size / μm Comparative example 1 Eu 0.008 Ca 0.992 AlSiN 3

100 0.669 653 15 Example 1 Ca 0.992 AlMo 0.1 Si 0.9 N 3 : Eu 0.008

100.5 0.6685 652 12 Example 2 Ca 0.992 AlMo 0.15 Si 0.85 N 3 : Eu 0.008

102 0.6682 652 12 Example 3 Ca 0.992 AlMo 0.2 Si 0.8 N 3 : Eu 0.008

103 0.6678 652 12 Example 4 Ca 0.992 AlMo 0.25 Si 0.75 N 3 : Eu 0.008

105 0.6673 651 12 Example 5 Ca 0.992 AlMo 0.3 Si 0.7 N 3 : Eu 0.008

104 0.6665 651 12 Example 6 Ca 0.992 AlMo 0.35 Si 0.65 N 3 : Eu...

Embodiment 23~35

[0048] The preparation method of Examples 23-35 is the same as that of Example 1, except that the concentration of Eu is changed. Table 2 shows the prepared samples and their performance parameters.

[0049] Table 2

[0050] Example structural formula light intensity x color coordinate Peak wavelength / nm Particle size / μm Example 23 Ca 0.996 AlMoN 3 : Eu 0.002

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com