Super-hydrophobic and anti-icing transparent coating and preparation method thereof

A transparent coating and super-hydrophobic technology, applied in coatings and other directions, can solve the problems of high risk, failure to meet the requirements of super-hydrophobic contact angle, complex preparation process of silica gel precursor, etc., and achieve good self-cleaning effect and high practicality. Value, the effect of large hydrophobic angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of superhydrophobic, anti-icing transparent coating, the steps are as follows:

[0054] 1) Add the silane coupling agent to the organic solvent, mix well and then add deionized water, uniformly disperse the inorganic nanoparticles into the organic solvent containing the silane coupling agent by ultrasonic or mechanical stirring, and disperse for 2~4 hours ; Suction filtration, washing with water, drying at 100°C, and grinding in a mortar to obtain inorganic nanoparticle fillers with superhydrophobic and anti-icing properties;

[0055] The inorganic nanoparticles are: one of hydrophilic nano-silicon dioxide, nano-titanium dioxide, and nano-alumina particles;

[0056]The dosage ratio of the inorganic nanoparticles, silane coupling agent, organic solvent and deionized water is: 5g~6g︰0.9g~4.7g︰36mL~60mL︰3.5mL~4.5mL;

[0057] 2) Add the corresponding quality of fluorosilane to the transparent fluorocarbon varnish, mix evenly at room temperature, and ...

Embodiment 1

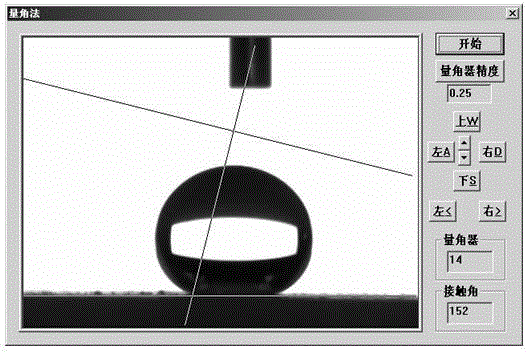

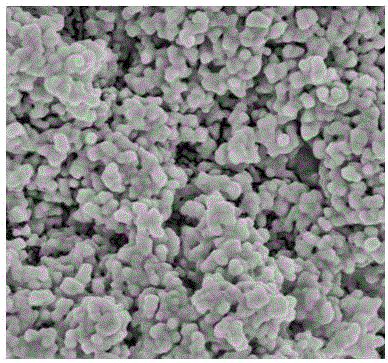

[0074] Such as Figure 1~6 Shown:

[0075] (1) Preparation of inorganic nanofillers:

[0076] Nano silica: 5g

[0077] Silane coupling agent (3-aminopropyltriethoxysilane): 1.48g

[0078] Toluene: 50mL

[0079] Deionized water: 3.5mL

[0080] Add the silane coupling agent 3-aminopropyltriethoxysilane to toluene, mix well and add deionized water; obtain a mixed solution; uniformly disperse nano-silica into the mixed solution by mechanical stirring, and disperse for 3.5 h; suction filtration, washing with water, and drying at 100°C; grinding in a mortar to obtain superhydrophobic and anti-icing inorganic nanoparticle fillers.

[0081] (2) The composition ratio of the coating composition is (mass percentage):

[0082] Fluorocarbon varnish: 30.71g

[0083] Per(thirteen)fluorooctyltriethoxysilane: 0.31g

[0084] Superhydrophobic nano silica: 4.91g

[0085] Thinner: 6.14g

[0086] Weigh the above composition according to the proportion, stir it for 90 minutes, make it full...

Embodiment 2

[0088] (1) Preparation of inorganic nanofillers:

[0089] Nano silica: 5g

[0090] Silane coupling agent (γ-(methacryloyloxy)propyltrimethoxysilane): 4.7g

[0091] Isopropanol: 36mL

[0092] Deionized water: 4.5mL

[0093] Add the silane coupling agent γ-(methacryloyloxy)propyltrimethoxysilane to isopropanol, mix well, add deionized water, and magnetically stir for 1 hour to obtain a mixed solution; The silicon oxide is evenly dispersed in the mixed solution, and dispersed for 4 hours; suction filtered, washed with water, and dried at 100°C; ground in a mortar, and superhydrophobic, anti-icing inorganic nanoparticle fillers are obtained.

[0094] (2) The composition ratio of the coating composition is (mass percentage):

[0095] Fluorocarbon varnish: 30.71g

[0096] Heptadecafluorodecyltrimethoxysilane: 0.31g

[0097] Hydrophobic nano silica: 4.91g

[0098] Thinner: 6.14g

[0099] Weigh the above composition according to the proportion, stir it for 90 minutes, make it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com