A kind of polypropylene composition and its preparation method and application

A polypropylene composition and composition technology, applied in the field of polymers, can solve the problems of unfavorable fast packaging production lines, increased processing costs, narrow processing window, etc., and achieve the effects of good mechanical properties, fast heat sealing speed, and low packaging cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of homemade aromatic copolyester: Add 600g terephthalic acid, 400g isophthalic acid, 20g phthalic acid, 600g ethylene glycol, 0.5g antimony trioxide and 0.2g trimethyl phosphate into the reaction kettle , and then replace the reactor with high-purity nitrogen, and the initial pressure is 0.12MPa. Stir to raise the temperature to 220°C, raise the pressure to 0.4MPa for the first contact reaction for 4 hours, then raise the temperature to 275°C, reduce the pressure to 60Pa for the second contact reaction for 1 hour, and extrude into strips under nitrogen pressure in a molten state. After water cooling, it is granulated by a granulator to obtain non-crystalline copolyester chips. Its intrinsic viscosity is 0.65dl / g, and its glass transition temperature range is 67°C.

Embodiment 2

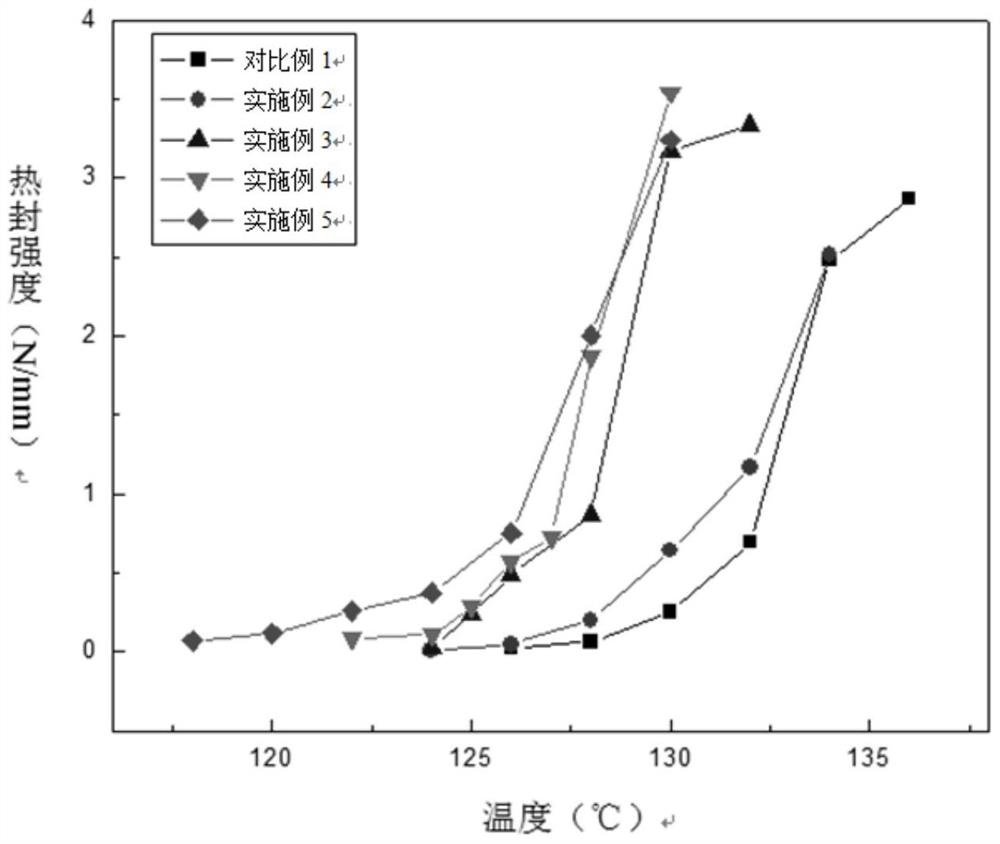

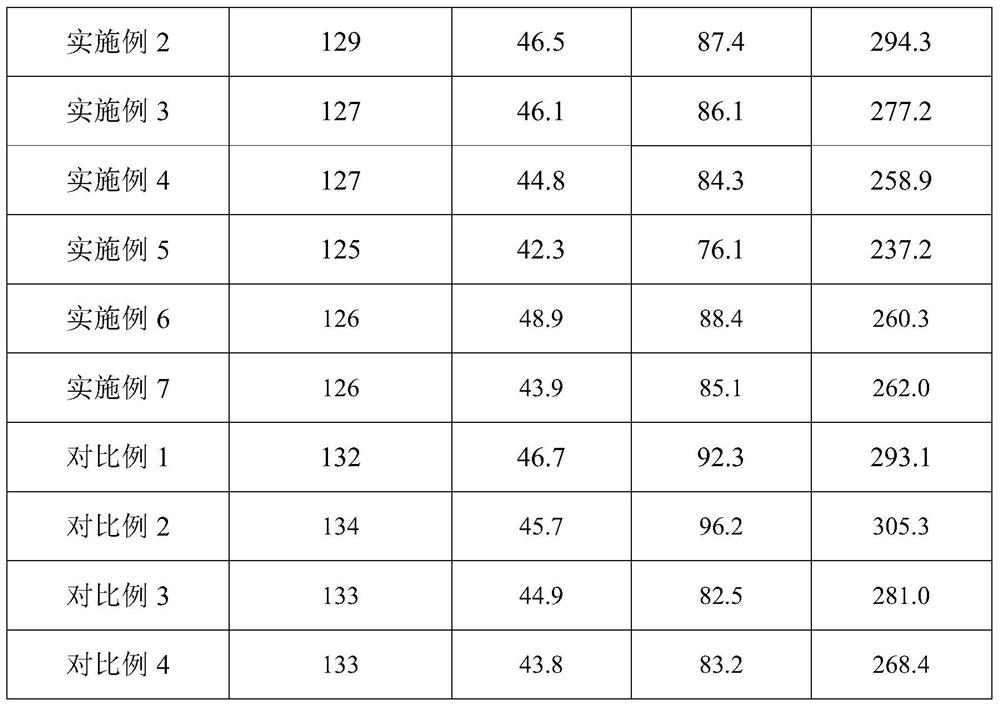

[0042] Yangzi Petrochemical ternary copolymerized polypropylene pellets PPR-FO7-V (containing 1.6 mol% of ethylene and 5.1 mol% of 1-butene, with a melting index of 6.2g / 10min and a melting point of 135°C) and Example 1 provide The self-made aromatic copolyester was mixed, and the polypropylene composition was prepared by melt blending at 200°C, wherein the content of the self-made aromatic copolyester was 5wt%. The polypropylene composition was formed into a film with a thickness of 0.2 mm using a single-screw caster with a screw temperature of 230°C. Determine the initial heat-sealing temperature and mechanical properties of the film, and the results are included in the figure 1 and Table 1.

Embodiment 3

[0044] Yangzi Petrochemical ternary copolymerized polypropylene pellets PPR-FO7-V (containing 1.6 mol% of ethylene and 5.1 mol% of 1-butene, with a melting index of 6.2g / 10min and a melting point of 135°C) and Example 1 provide The self-made aromatic copolyester was mixed, and the polypropylene composition was prepared by melt blending at 200°C, wherein the content of the self-made aromatic copolyester was 10wt%. The polypropylene composition was formed into a film with a thickness of 0.1 mm using a single-screw casting machine, and the temperature of the screw was 200°C. Determine the initial heat-sealing temperature and mechanical properties of the film, and the results are included in the figure 1 and Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com