A method for separation and extraction of chitotetraose monomer based on molecular imprinting technology

A molecular imprinting technology, molecular imprinting technology, applied in the direction of amino sugar, chemical instruments and methods, sugar derivatives, etc., can solve the problems of low purity, high price, and separation research has not yet been published, and achieve simple separation and extraction process and market competition The effect of strong force and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

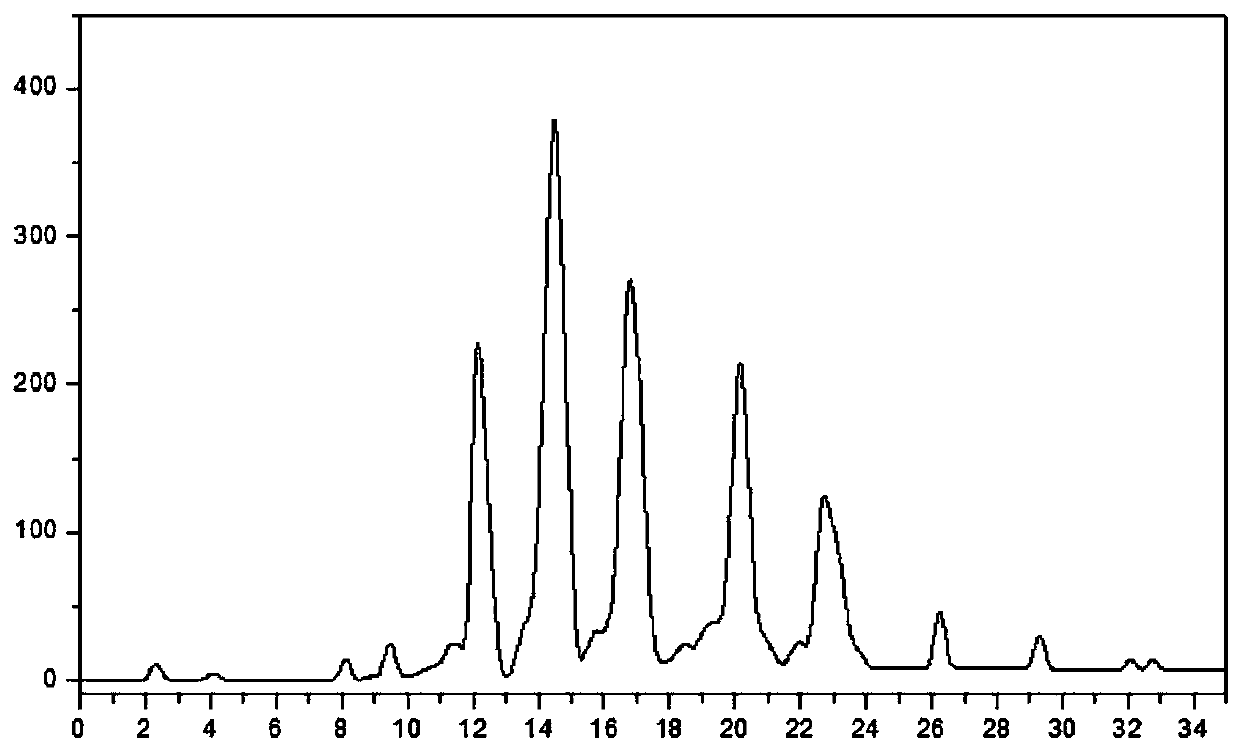

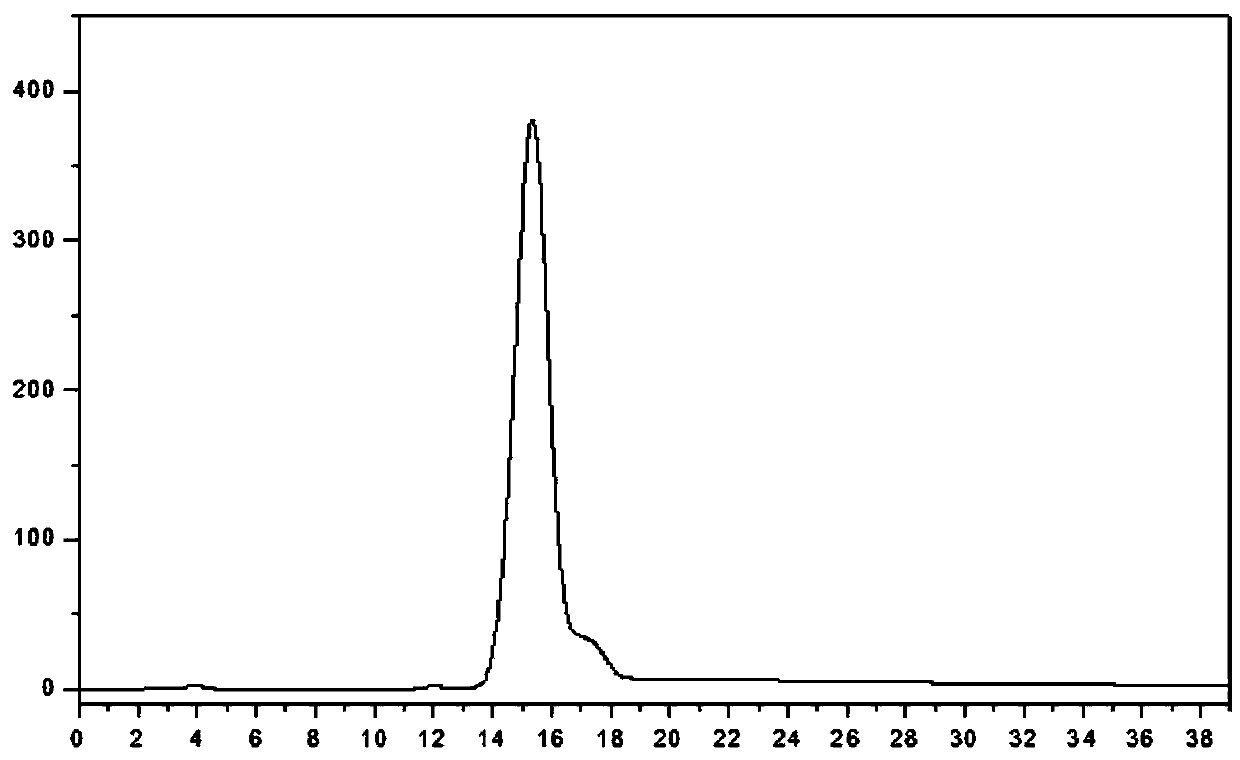

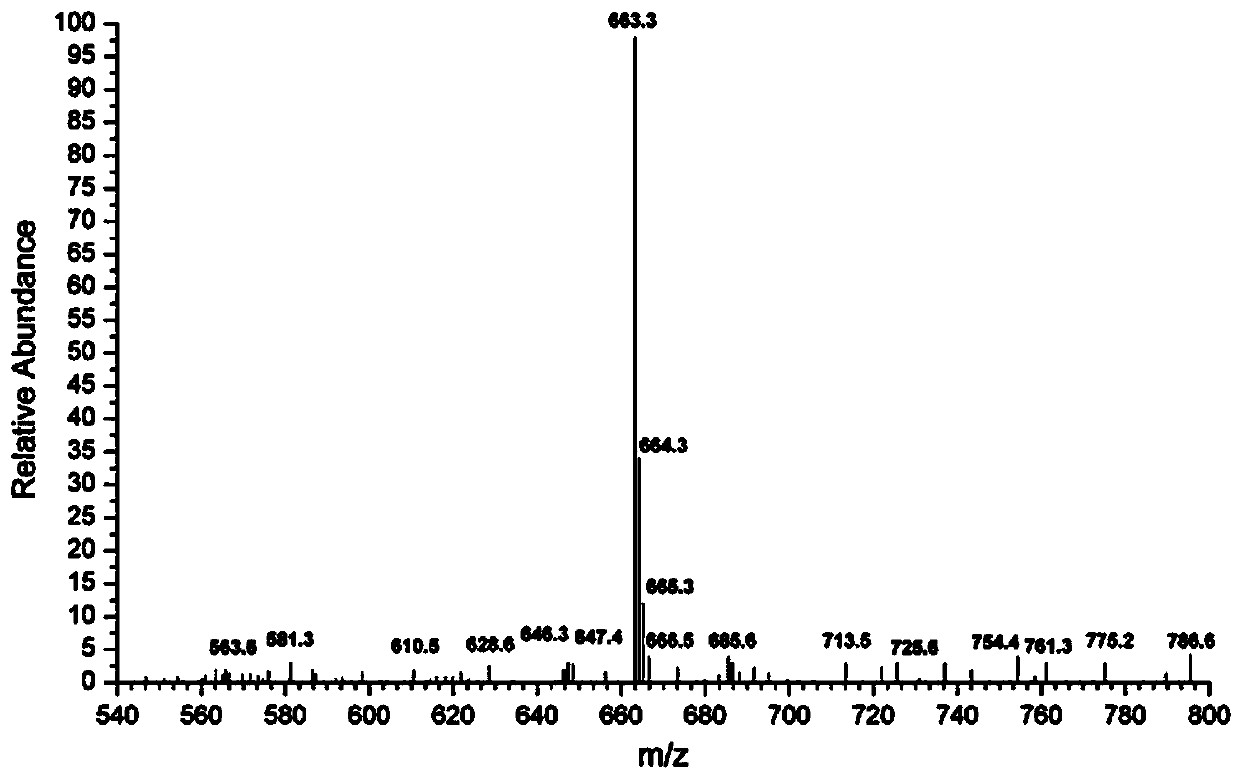

Image

Examples

Embodiment 1

[0027] Preparation: Take 65kg ethylene glycol dimethacrylate (EGDMA); 5kg N-[2-(dimethylamino)ethyl]-N'-[(2-hydroxy-4-vinylphenyl)]oxamide Binuclear zinc-chitotetraose; 5kg petroleum ether 90-120; 0.5kg polyvinyl alcohol (PVA); 0.05kg azobisisobutyronitrile (AIBN);

[0028] Preparation of chitotetraose molecularly imprinted resin: N-[2-(dimethylamino)ethyl]-N'-[(2-hydroxyl-4-vinylphenyl)] oxamide dinuclear zinc-chitotetraose and even Azodiisobutyronitrile is dissolved in absolute ethanol according to the proportion by weight, so that N-[2-(dimethylamino)ethyl]-N'-[(2-hydroxyl-4-vinylphenyl)] grass The mass percent concentration of amide dinuclear zinc-chitotetraose and azobisisobutyronitrile in dehydrated alcohol is 10%, then the mixed solution is mixed with ethylene glycol dimethacrylate, petroleum ether 90-120; Under strong stirring, slowly add this mixed system into a three-necked flask containing polyvinyl alcohol, pass through nitrogen to remove oxygen for 30 minutes; he...

Embodiment 2

[0037] Preparation: Take 80kg ethylene glycol dimethacrylate (EGDMA); 10kg N-[2-(dimethylamino)ethyl]-N'-[(2-hydroxy-4-vinylphenyl)]oxamide Binuclear zinc-chitotetraose; 7kg petroleum ether 90-120; 1kg polyvinyl alcohol (PVA); 0.15kg azobisisobutyronitrile (AIBN);

[0038] Preparation of chitotetraose molecularly imprinted resin: N-[2-(dimethylamino)ethyl]-N'-[(2-hydroxyl-4-vinylphenyl)] oxamide dinuclear zinc-chitotetraose and even Azodiisobutyronitrile is dissolved in absolute ethanol according to the proportion by weight, so that N-[2-(dimethylamino)ethyl]-N'-[(2-hydroxyl-4-vinylphenyl)] grass The mass percent concentration of amide dinuclear zinc-chitotetraose and azobisisobutyronitrile in dehydrated alcohol is 15%, then the mixed solution is mixed with ethylene glycol dimethacrylate, petroleum ether 90-120; Under strong stirring, slowly add this mixed system into a three-necked flask containing polyvinyl alcohol, pass through nitrogen to remove oxygen for 30 minutes; hea...

Embodiment 3

[0047] Preparation: Take 95kg ethylene glycol dimethacrylate (EGDMA); 15kg N-[2-(dimethylamino)ethyl]-N'-[(2-hydroxy-4-vinylphenyl)]oxamide Binuclear zinc-chitotetraose; 9kg petroleum ether 90-120; 1.5kg polyvinyl alcohol (PVA); 0.3kg azobisisobutyronitrile (AIBN);

[0048] Preparation of chitotetraose molecularly imprinted resin: N-[2-(dimethylamino)ethyl]-N'-[(2-hydroxyl-4-vinylphenyl)] oxamide dinuclear zinc-chitotetraose and even Azodiisobutyronitrile is dissolved in absolute ethanol according to the proportion by weight, so that N-[2-(dimethylamino)ethyl]-N'-[(2-hydroxyl-4-vinylphenyl)] grass The mass percent concentration of amide dinuclear zinc-chitotetraose and azobisisobutyronitrile in dehydrated alcohol is 20%, then the mixed solution is mixed with ethylene glycol dimethacrylate, petroleum ether 90-120; Under strong stirring, slowly add this mixed system into a three-necked flask containing polyvinyl alcohol, pass through nitrogen to remove oxygen for 30 minutes; he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com