Foaming cement and foaming polyurethane interpenetrating network thermal insulation board for external wall and preparation of foaming cement and foaming polyurethane interpenetrating network thermal insulation board

A technology for foaming polyurethane and external wall thermal insulation boards, which is applied in thermal insulation, ceramic products, other household appliances, etc., can solve the problems of low strength, limited popularization and application, cracking, etc., and achieves the effect of overcoming easy powdering and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment first configures the A component cement slurry:

[0023] (1) Component A (by weight): 95 parts of cement, 2.5 parts of early strength agent, 1.5 parts of water reducer, 5.0 parts of fly ash, 1.0 part of PP fiber (8-10mm), calcium stearate ( CP) 2.0 parts, H 2 30 parts of O (water at room temperature), 2.0 parts of paraffin, fully mix the above slurry, and then add foaming agent H 2 o 2 (27.5%) 8.0 parts, stirred rapidly and poured into a 1.0×2.0m mold, and left to stand to obtain a foamed cement board.

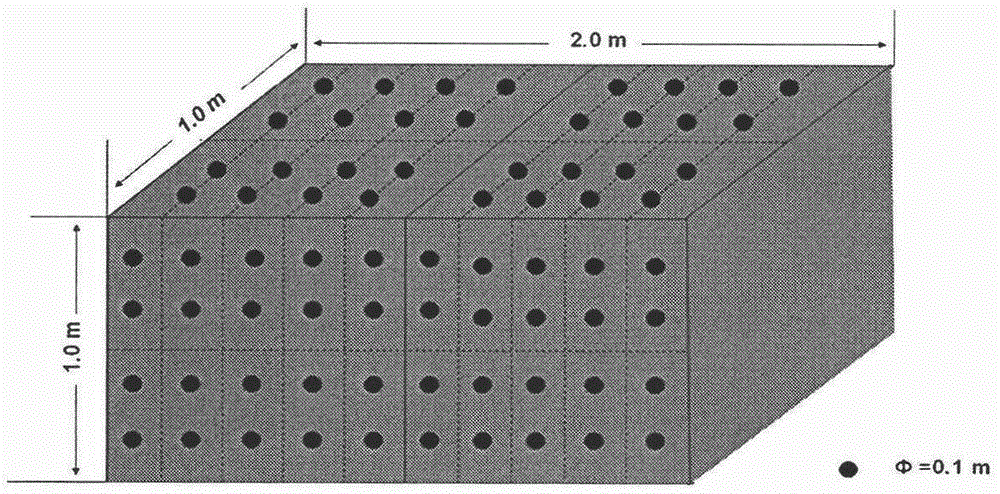

[0024] After the above-mentioned foamed cement board is left to stand for 4 to 24 hours, the foamed cement board has a certain strength. figure 1 Make the jack.

[0025] Weigh component B (by weight): 45 parts of polyurethane black material (PU), 35 parts of white material, 3.0 parts of triethanolamine (TEA), 10.0 parts of foaming agent water, 1.0 part of organotin catalyst and mix well;

[0026] Use a pressurized grouting machine to pressurize and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com