Water level detecting circuit for water treatment equipment

A technology for water treatment equipment and water level detection, applied in water/sewage treatment, water treatment parameter control, water/sludge/sewage treatment, etc., can solve the problems of high investment, large system, long treatment process, etc., and achieve reasonable Water level control, simple circuit structure, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

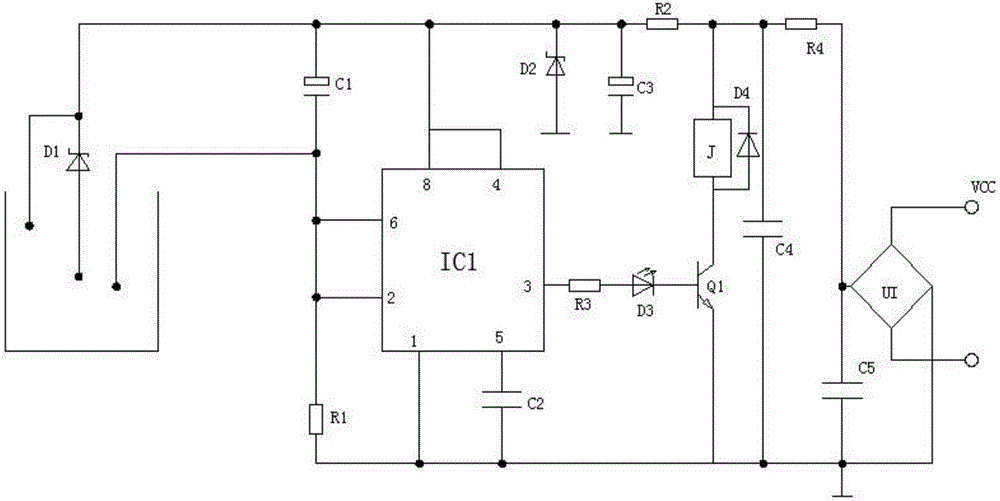

[0033] A water level detection circuit for water treatment equipment, using three different heights of water level detection lines to detect the water level, can safely and quickly let the user know the current water level, and automatically brake the relay, so as to achieve reasonable control water level purposes such as figure 1 As shown, the following arrangement structure is adopted in particular: a detection circuit, a main processing circuit, a relay circuit and a power supply circuit are provided, the detection circuit is set in the water level detection area of the water treatment equipment, and the detection circuit is connected to the main processing circuit connected; the main processing circuit is connected to the relay circuit, and the power supply circuit is respectively connected to the detection circuit, the main processing circuit and the relay circuit; The detection line of the water level and the capacitor C1, and a Zener diode D1 is also arranged on the d...

Embodiment 2

[0035] This embodiment is further optimized on the basis of the above-mentioned embodiments. In order to better realize the present invention, the following arrangement structure is adopted in particular: the negative electrode of the Zener diode D1 is connected to the first end of the capacitor C1.

Embodiment 3

[0037] This embodiment is further optimized on the basis of any of the above-mentioned embodiments. Further, in order to better realize the present invention, the real-time sensed water level data information can be effectively processed, and then used to control the relay circuit, so that The equipment controlled by the relay circuit performs the corresponding braking operation, such as figure 1 As shown, the following arrangement structure is adopted in particular: a processing chip IC1, a capacitor C2, a resistor R1 and an indicator circuit are arranged in the main processing circuit, and the second end of the capacitor C1 is respectively connected to pins 2 and 2 of the processing chip IC1. Pin 6 is connected to the first end of resistor R1, the second end of resistor R1 is connected to pin 1 of processing chip IC1, pin 1 of processing chip IC1 is connected to pin 3 of processing chip IC1 through capacitor C2; processing chip IC1 Pin 3 of the IC1 is connected to the relay ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com