A process for purifying boron trifluoride gas by low-temperature rectification

A boron trifluoride, low temperature rectification technology, applied in the direction of boron halide compound, boron halide, etc., can solve the problem of unstable product quality, and achieve the effect of simple and stable temperature control, low equipment investment and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

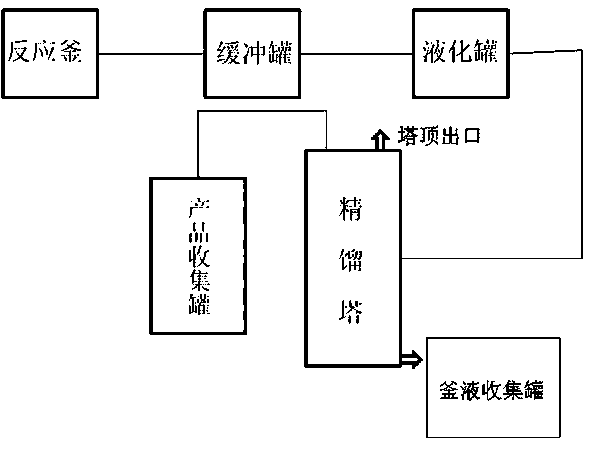

Method used

Image

Examples

example 1

[0028] The boron trifluoride raw material gas is compressed first, and the raw material gas composition is: SO 2 6000ppm, SO 3 50ppm, HF100ppm, SiF 4 15ppm, air (N 2 +O 2 ) 1.2%, BF 3 98.18%. Compress the gas to 3.5MPa, enter the liquefaction tank for liquefaction, and then enter the rectification tower. The temperature of the refrigerant in the top condenser is -38°C to -40°C, the temperature of the material in the tower kettle is 12°C-15°C, and the pressure of the rectification tower is controlled At 3.35-3.4MPa. The feed rate is 110-120KG / h. The continuous rectification has a stable discharge rate of 100-110KG / h, and the product analysis result is obtained: SO 2 12ppm, SO 3 5ppm, HF 3ppm, SiF 4 14ppm, air (N 2 +O 2 ) 251ppm, BF 3 99.97%.

example 2

[0030] The boron trifluoride raw material gas is compressed first, and the raw material gas composition is: SO 2 8500ppm, SO 3 70ppm, HF110ppm, SiF 4 16ppm, air (N 2 +O 2 ) 1.1%, BF 3 98.03%. Compress the gas to 3.3MPa, enter the liquefaction tank for liquefaction, and then enter the rectification tower. The temperature of the refrigerant in the top condenser is -40°C to -42°C, the temperature of the material in the tower kettle is 12°C-15°C, and the pressure of the rectification tower is controlled At 3.2-3.25MPa. The feed rate is 100-110KG / h. The continuous rectification has a stable discharge rate of 90-100KG / h, and the product analysis result is obtained: SO 2 15ppm, SO 3 6ppm, HF 3ppm, SiF 4 14ppm, air (N 2 +O 2 ) 211ppm, BF 3 99.98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com