Nitrogen-doped niobium carbide nanosheets and preparation method thereof

A niobium carbide nanometer and nitrogen doping technology, applied in chemical instruments and methods, carbon compounds, nanotechnology, etc., can solve problems such as few reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

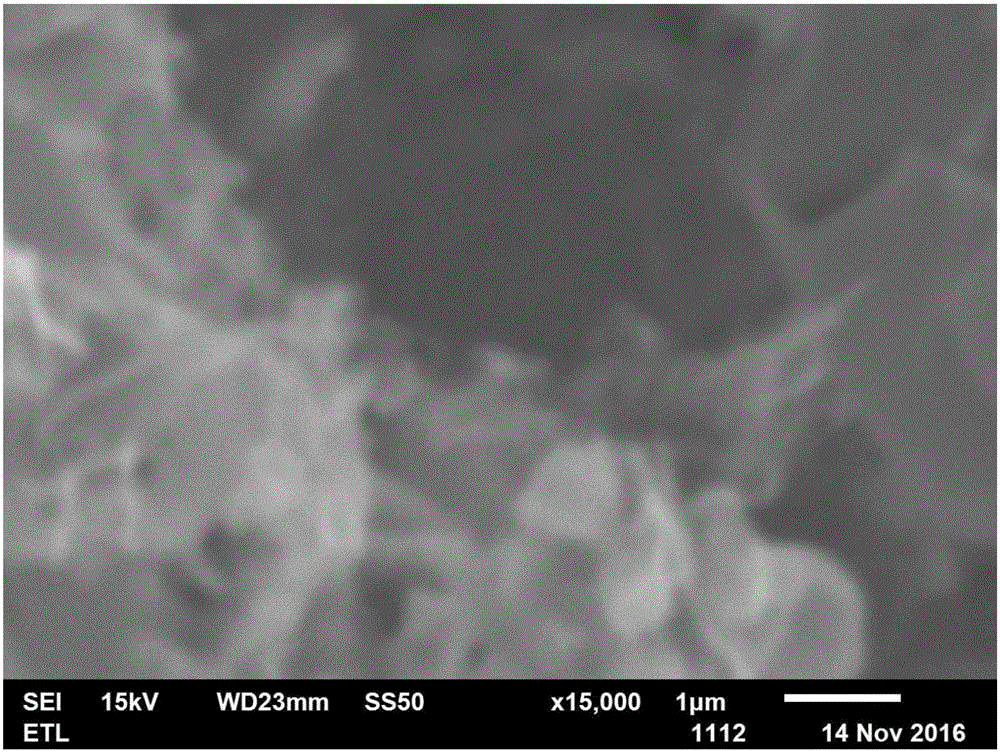

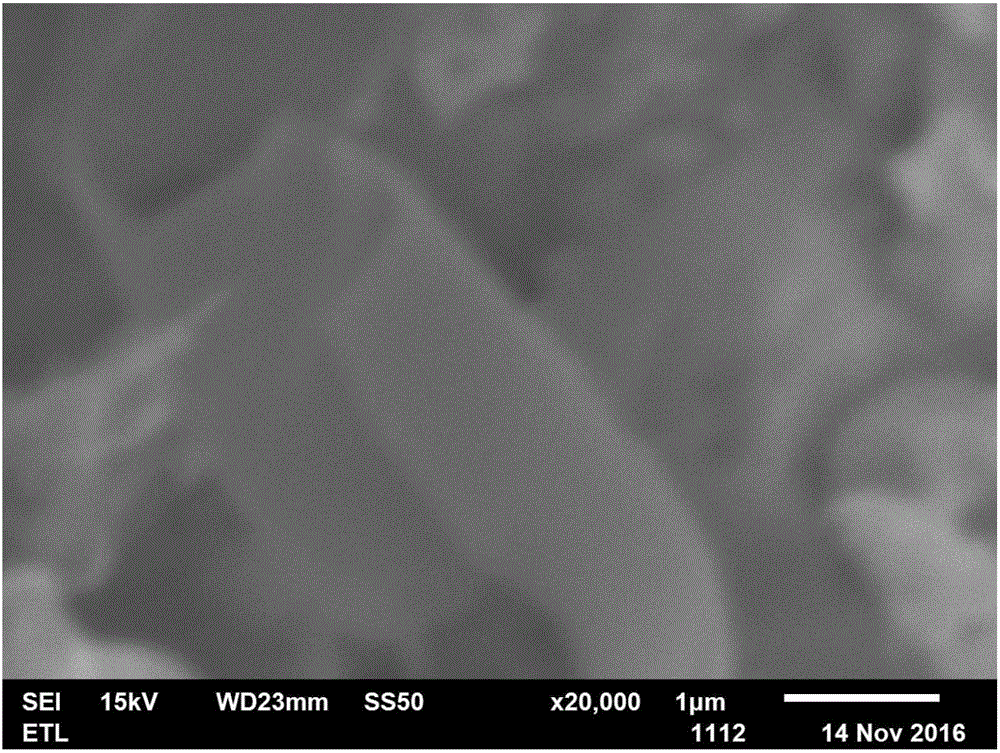

[0020] First, 1.3292g of Nb 2 o 5 , 2.4748g NiCl 2 ·6H 2 O, 3.1573 g of C 3 h 6 N 6 Put it in a ball mill jar and mill it in a ball mill for 1 hour to make it fully mixed. After taking it out, put it in a mortar and grind until it becomes powder (grinding is for more convenient performance characterization, and no grinding will not affect the implementation of the present invention), and vacuum-dry at 60° C. for 20 minutes. Put the dried powder in a graphite box, cover it, and put it in a fixed tube atmosphere furnace (CVD tube furnace). After vacuuming, nitrogen gas is introduced, and the parameters are set, and the temperature is raised to 1100 at 5°C / min. ℃, and keep it warm for 2 hours, then cool down with the furnace to get the final product. (See figure 1 , figure 2 )

Embodiment 2

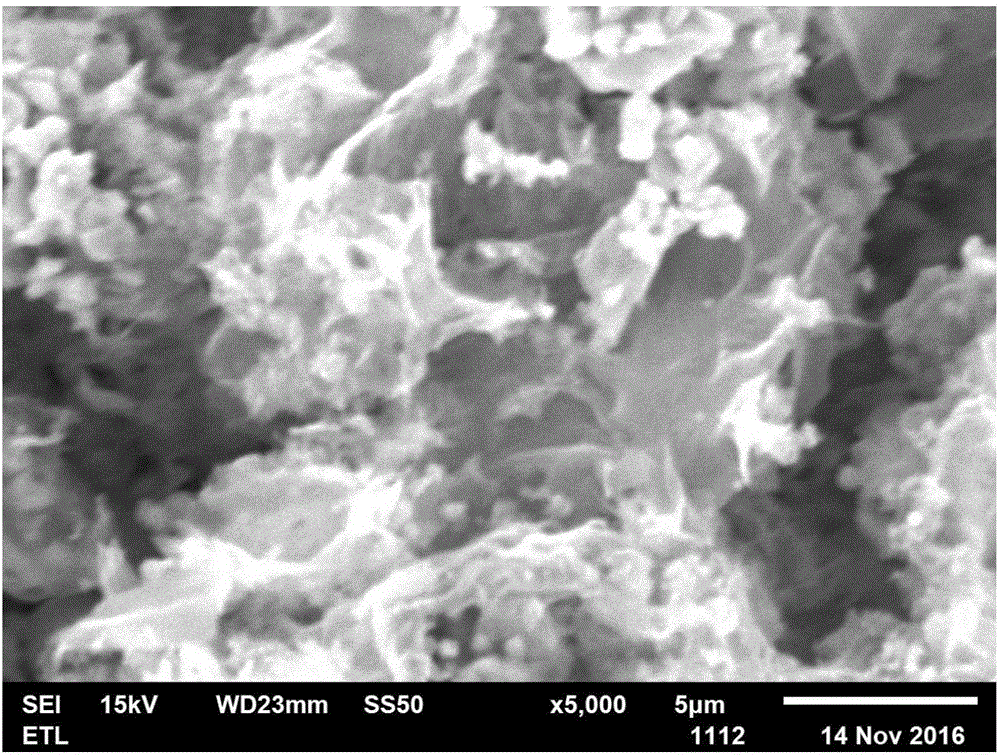

[0022] First, 1.3265g of Nb 2 o 5 , 4.7534g NiCl 2 ·6H 2 O, 3.1507g of C 3 h 6 N 6 Put it in a ball mill jar and mill it in a ball mill for 1 hour to make it fully mixed. After taking it out, grind it in a mortar until it becomes powder, and dry it under vacuum at 60°C for 20 minutes. Put the dried powder in a graphite box, cover it, put it in a CVD tube furnace, pump it into argon after vacuuming, set the parameters, raise the temperature to 1200°C at 7°C / min, and keep it warm for 3 hours , with furnace cooling to obtain the final product. (See image 3 )

Embodiment 3

[0024] First, 1.3292g of Nb 2 o 5 , 3.6754 g CoCl 2 ·6H 2 O, 3.1573 g of C 3 h 6 N 6 Put it in a ball mill jar and mill it in a ball mill for 1 hour to make it fully mixed. After taking it out, put it in a mortar and grind until it becomes powder, and dry it under vacuum at 60°C for 20 minutes. Put the dried powder in a graphite box, cover it, and put it in a CVD tube furnace. After vacuuming, nitrogen gas is introduced, and the parameters are set. The temperature is raised to 1100°C at a rate of 5°C / min, and the temperature is kept for 2 hours. Cool to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com