Biomass-based N, S and P-containing co-doped porous carbon and application thereof

A technology of porous carbon and biomass, which is applied in the manufacture of carbon compounds, hybrid/electric double layer capacitors, inorganic chemistry, etc., can solve the problems of environmental pollution, waste of resources, etc., and achieve the effect of abundant raw materials, low cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] (5) Preparation of activated carbon electrode: take the prepared activated carbon as the active material, weigh the active material with a mass ratio of 8:1:1, the conductive agent acetylene black, and the binder polytetrafluoroethylene (PTFE) into the agate grinder. Grind in a bowl, grind until viscous, and then apply it on a nickel foam with a diameter of 1 cm. After drying, press it into a flat sheet with a tablet press (pressure 10 MPa).

[0035] (6) Electrochemical performance test: use the electrochemical workstation to test the performance of materials such as cyclic voltammetry, constant current charge and discharge, and AC impedance, and use two-electrode systems and three-electrode systems to measure them in different electrolytes.

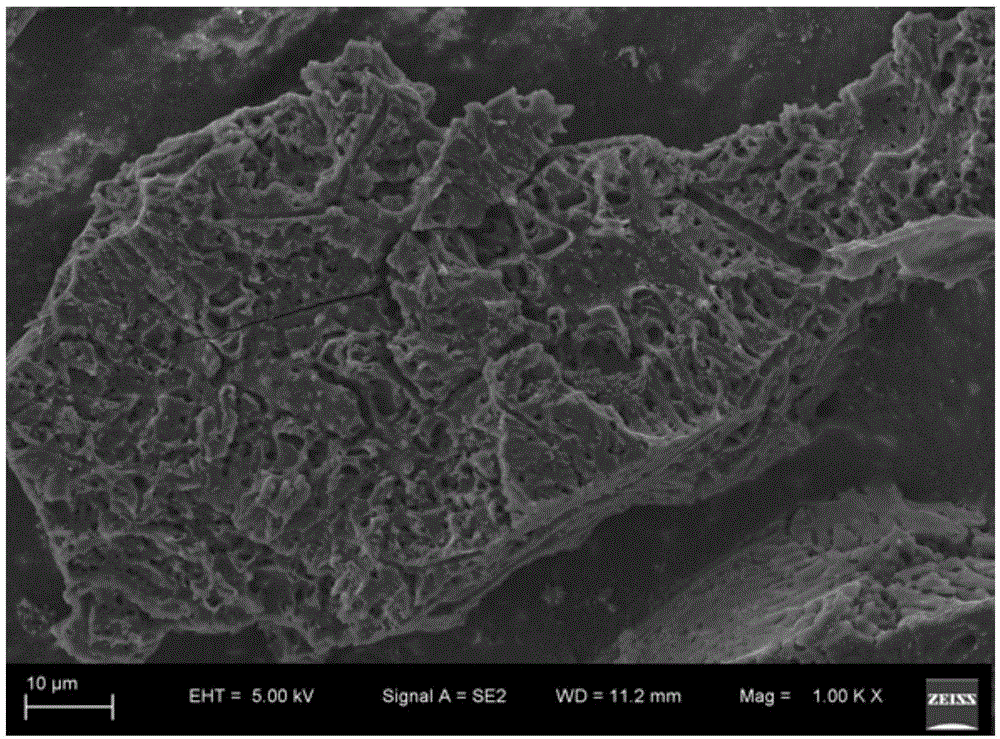

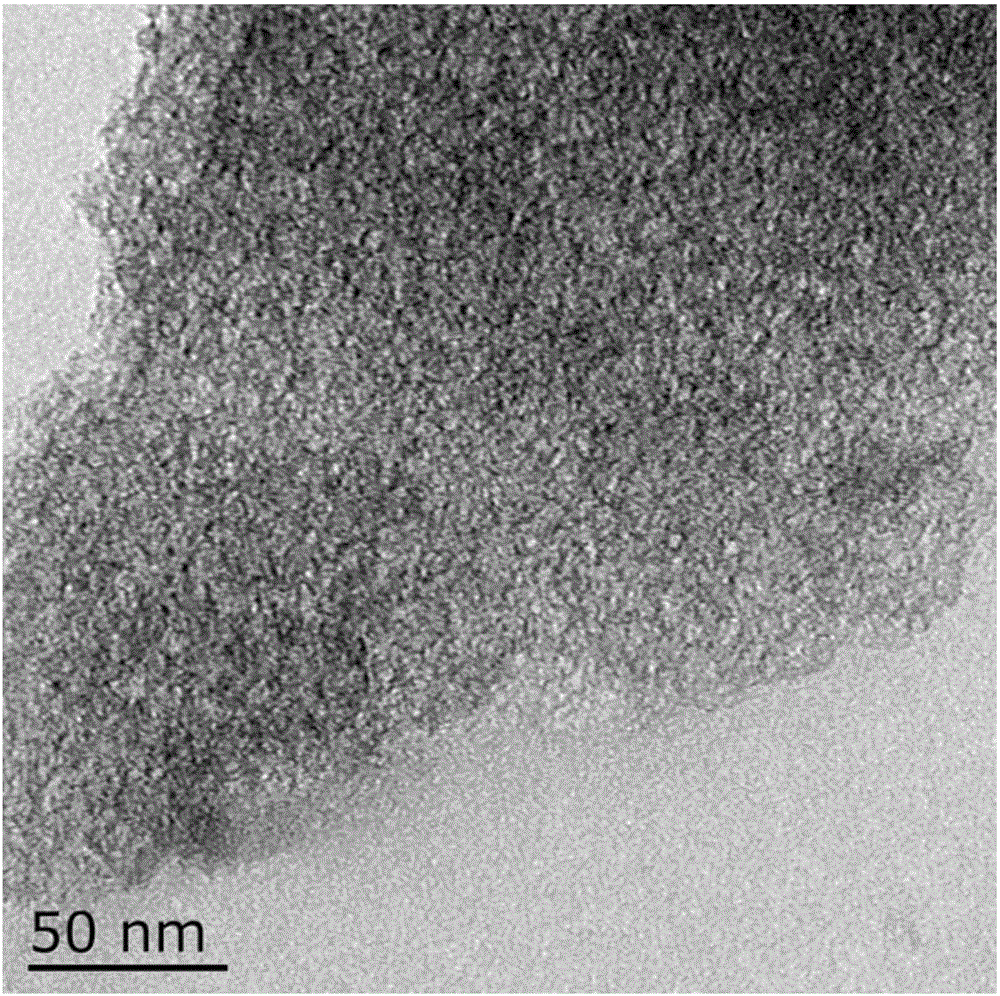

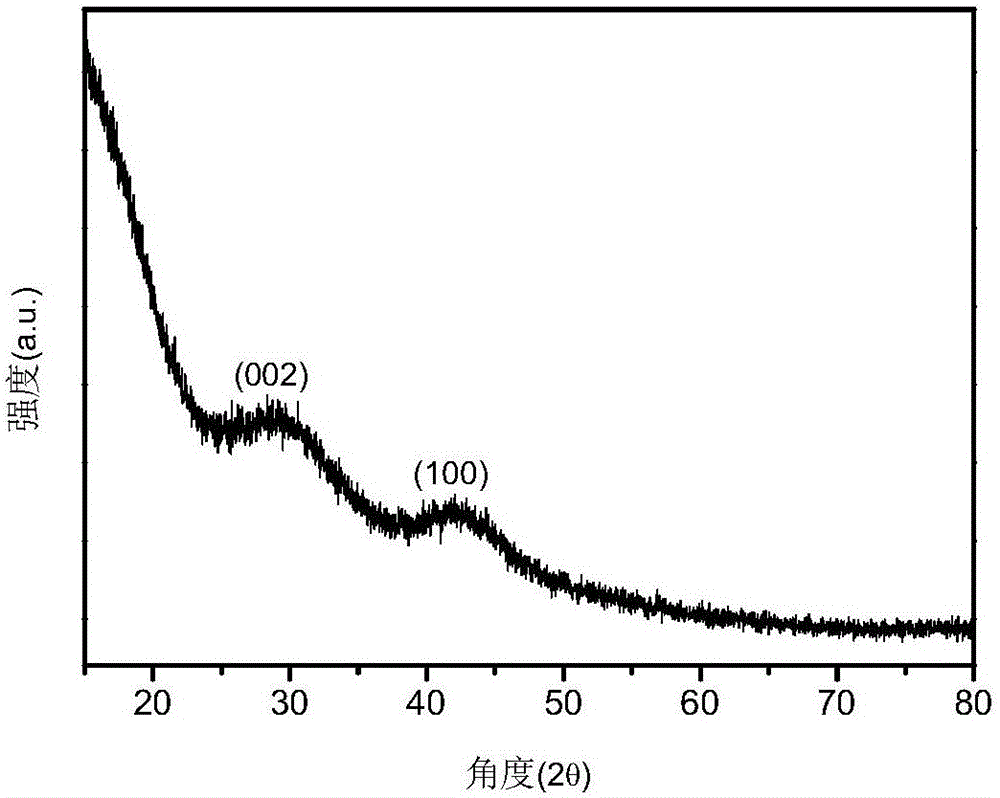

[0036] The invention prepares palm shell activated carbon with superior performance under the appropriate alkali-carbon ratio and heating temperature, with a specific surface area of 2760 m 2 / g, pore volume up to 1.6 cm 3 / g, ...

Embodiment 1

[0038] (1) Carbonization: Weigh a certain amount of dry palm shell raw materials and place them in a quartz crucible and heat them in a tube furnace. h, take it out after standing to normal temperature, and obtain the black palm shell carbonized material, which is pulverized and sieved for subsequent use.

[0039] (2) Impregnation: According to the alkali-carbon ratio of 3:1, weigh 6 g of activator KOH in a beaker, then weigh 2 g of palm shell carbonized material and mix it with it, add an appropriate amount of distilled water, stir to mix evenly, and place at 100 °C Dry in an oven for activation.

[0040] (3) Activation: During the activation process, the palm shell carbonized material impregnated with KOH is placed in a nickel crucible and placed in a tube furnace, and the mixture is heated to 800 ~ Keep at 1000°C for 1 h.

[0041](4) Washing and drying: After the activation, cool naturally, add 1M hydrochloric acid solution to wash after taking it out, put it in a beaker ...

Embodiment 2

[0045] (1) Carbonization: Weigh a certain amount of dry palm shell raw materials and place them in a quartz crucible and heat them in a tube furnace. h, take it out after standing to normal temperature, and obtain the black palm shell carbonized material, which is pulverized and sieved for subsequent use.

[0046] (2) Impregnation: According to the alkali-carbon ratio of 4:1, weigh 8 g of activator KOH in a beaker, then weigh 2 g of palm shell carbonized material and mix it with it, add an appropriate amount of distilled water, stir to mix evenly, and place at 100 °C Dry in an oven for activation.

[0047] (3) Activation: During the activation process, the palm shell carbonized material impregnated with KOH was placed in a nickel crucible and placed in a tube furnace, and the mixture was heated to 800-800 °C at a rate of 5 °C / min under a nitrogen atmosphere. Keep at 1000°C for 1 h.

[0048] (4) Washing and drying: After activation, cool naturally, add 1 M hydrochloric acid s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com